Preparation method of multilayer PEG-DMA hydrogel

A PEG-DMA and hydrogel technology, which is applied in the field of PEG-DMA hydrogel preparation, can solve problems such as detachment, instability, and poor mechanical strength, and achieve good softness, avoid deformation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

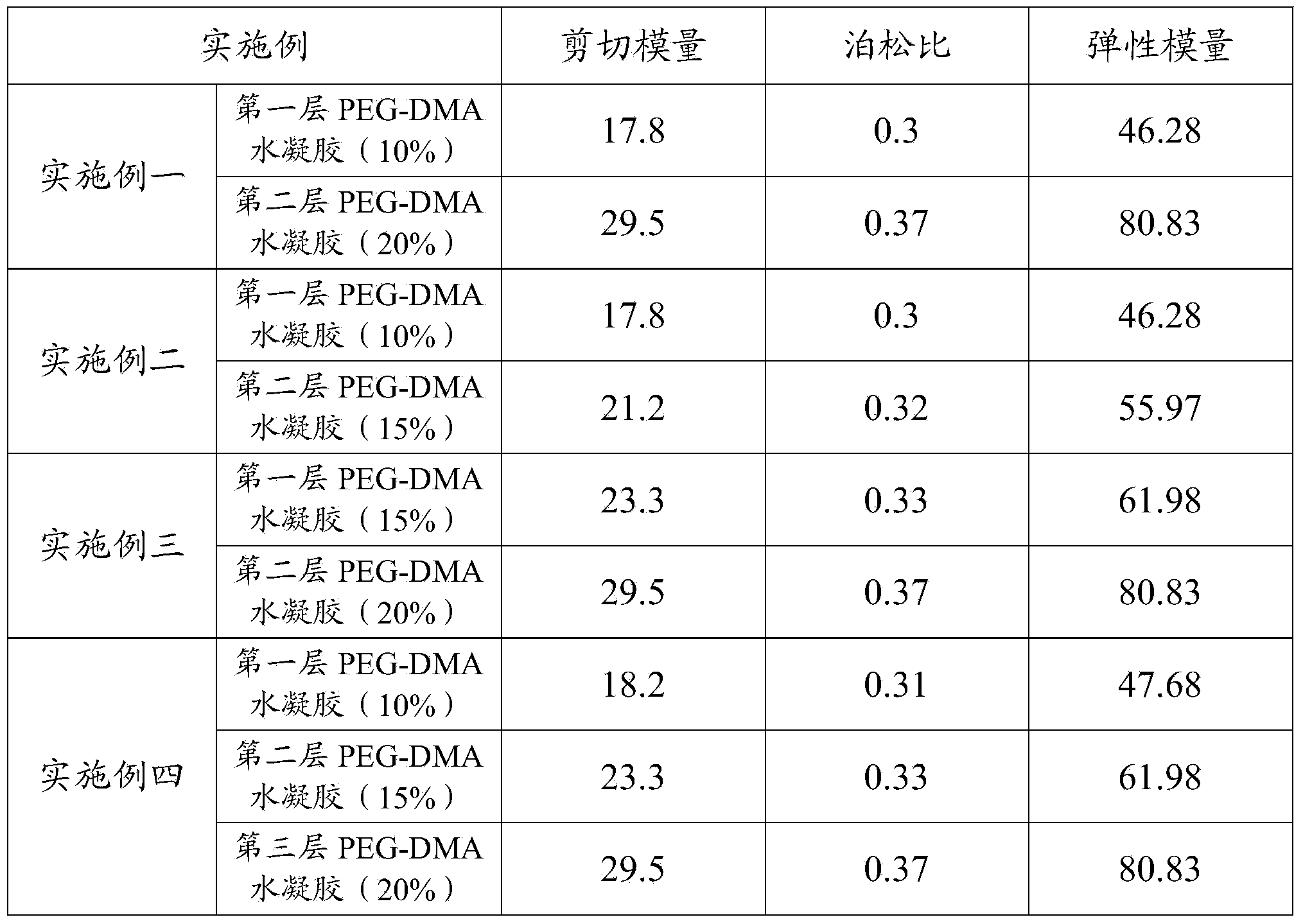

[0033] Example 1: Preparation of double-layer PEG-DMA hydrogel

[0034] Take two glass clips, a U-shaped silicone rubber strip with a thickness of 2mm and several fixing clips. Place the U-shaped silicone rubber strip between the two glass clips, and then use the fixing clip to connect the glass clip to the silicone rubber. The strips are clamped to make a U-shaped single-layer mold with a thickness of 2 mm.

[0035] Add 20mL deionized water and 2g PEG-DMA to the beaker, stir evenly to obtain a 10% mass concentration PEG-DMA solution; then add 0.1mL 2-hydroxy-2-methylpropiophenone and wrap the beaker with tin foil to avoid Stir lightly for more than 30 minutes to prepare the first layer of PEG-DMA solution; use a syringe to inject the first layer of PEG-DMA solution into a U-shaped single-layer mold, and then place it in a UV crosslinker for light crosslinking for 2 minutes to obtain The first layer of PEG-DMA hydrogel with a mass concentration of 10% and a thickness of 2mm.

[003...

Embodiment 2

[0039] Example 2: Preparation of double-layer PEG-DMA hydrogel

[0040] Take two glass clips, a U-shaped silicone rubber strip with a thickness of 2mm and several fixing clips. Place the U-shaped silicone rubber strip between the two glass clips, and then use the fixing clip to connect the glass clip to the silicone rubber. The strips are clamped to make a U-shaped single-layer mold with a thickness of 2 mm.

[0041] Add 20mL deionized water and 2g PEG-DMA to the beaker, stir evenly to obtain a 10% mass concentration PEG-DMA solution; then add 0.1mL 2-hydroxy-2-methylpropiophenone and wrap the beaker with tin foil to avoid Stir lightly for more than 30 minutes to prepare the first layer of PEG-DMA solution; use a syringe to inject the first layer of PEG-DMA solution into a U-shaped single-layer mold, and then place it in a UV crosslinker for light crosslinking for 2 minutes to obtain The first layer of PEG-DMA hydrogel with a mass concentration of 10% and a thickness of 2mm.

[004...

Embodiment 3

[0045] Example 3: Preparation of double-layer PEG-DMA hydrogel

[0046] Take two glass clips, a U-shaped silicone rubber strip with a thickness of 4mm and several fixing clips. Place the U-shaped silicone rubber strip between the two glass clips, and then use the fixing clip to connect the glass clip to the silicone rubber. The strips are clamped to make a U-shaped single-layer mold with a thickness of 4 mm.

[0047] Add 20mL of deionized water and 3g of PEG-DMA to the beaker and stir well to obtain a PEG-DMA solution with a mass concentration of 15%; then add 0.1mL of 2-hydroxy-2-methylpropiophenone and wrap the beaker with tin foil to avoid Stir lightly for more than 30 minutes to prepare the first layer of PEG-DMA solution; use a syringe to inject the first layer of PEG-DMA solution into a U-shaped single-layer mold, and then place it in a UV crosslinker for light crosslinking for 2 minutes to obtain The first layer of PEG-DMA hydrogel with a mass concentration of 15% and a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com