A new single-shaft natural gas combined cycle heating unit system

A technology of combined cycle and heat supply units, applied in mechanical equipment, steam engine devices, machines/engines, etc., can solve the problems of no steam entering the pure condensing steam turbine, the efficiency of the steam turbine body decreases, etc., and achieve the effect of improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

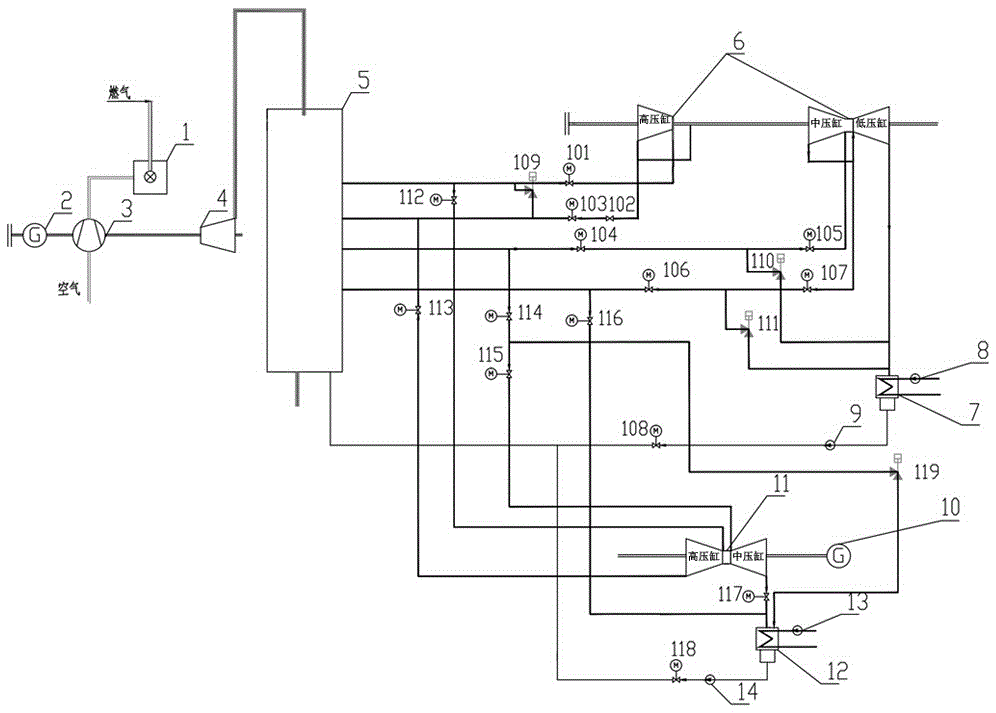

[0013] Such as figure 1 As shown, the present invention is a novel uniaxial natural gas combined cycle heating unit system, which includes a combustion chamber 1, the combustion chamber 1 is connected to the compressor 3, the compressor 3 is connected to the generator I2, and the gas turbine 4, and the gas turbine 4 is connected to the waste heat boiler 5 is connected, the waste heat boiler 5 is connected with the thermal system of the steam turbine and the thermal system of the back pressure machine, and the thermal system of the steam turbine and the thermal system of the back pressure machine are connected through the control system. The steam turbine thermal system includes a pipeline I equipped with a high-pressure bypass valve 109 and a shut-off valve I101, a pipeline II equipped with a check valve 102 and a shut-off valve II103, one end of the pipeline I is connected to the waste heat boiler 5, and the other One end is connected to the main steam valve of the condensing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com