Debugging device and debugging method for a split-type power stage servo valve

A debugging method and servo valve technology, applied in the field of servo valve debugging, can solve problems such as inability to accurately locate problems, and achieve the effect of improving test efficiency and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

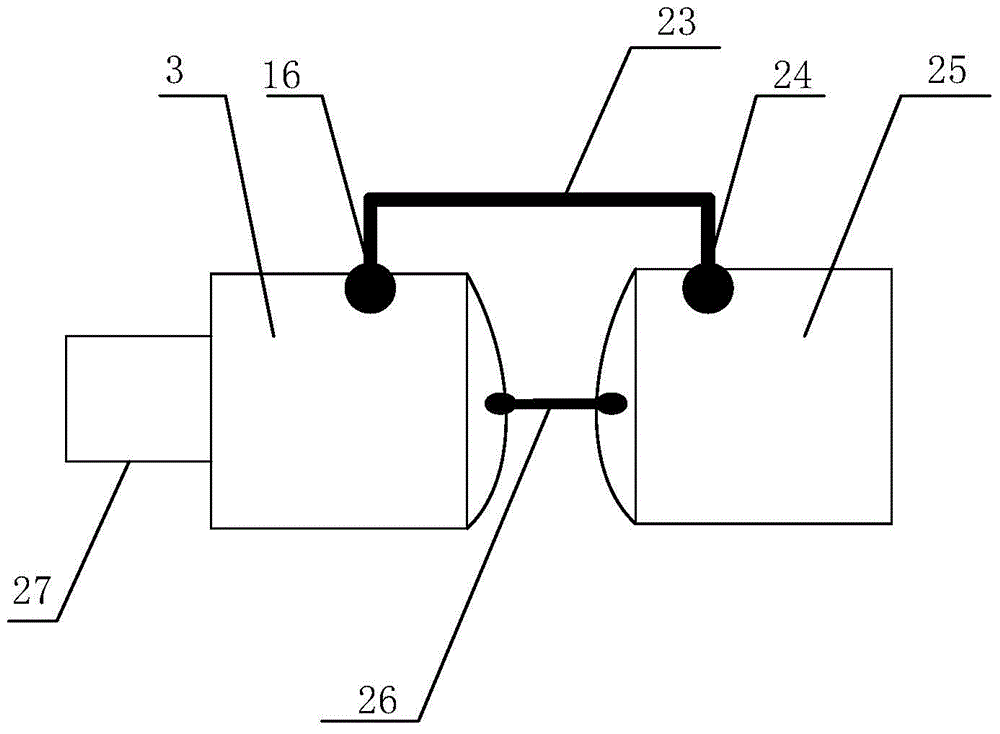

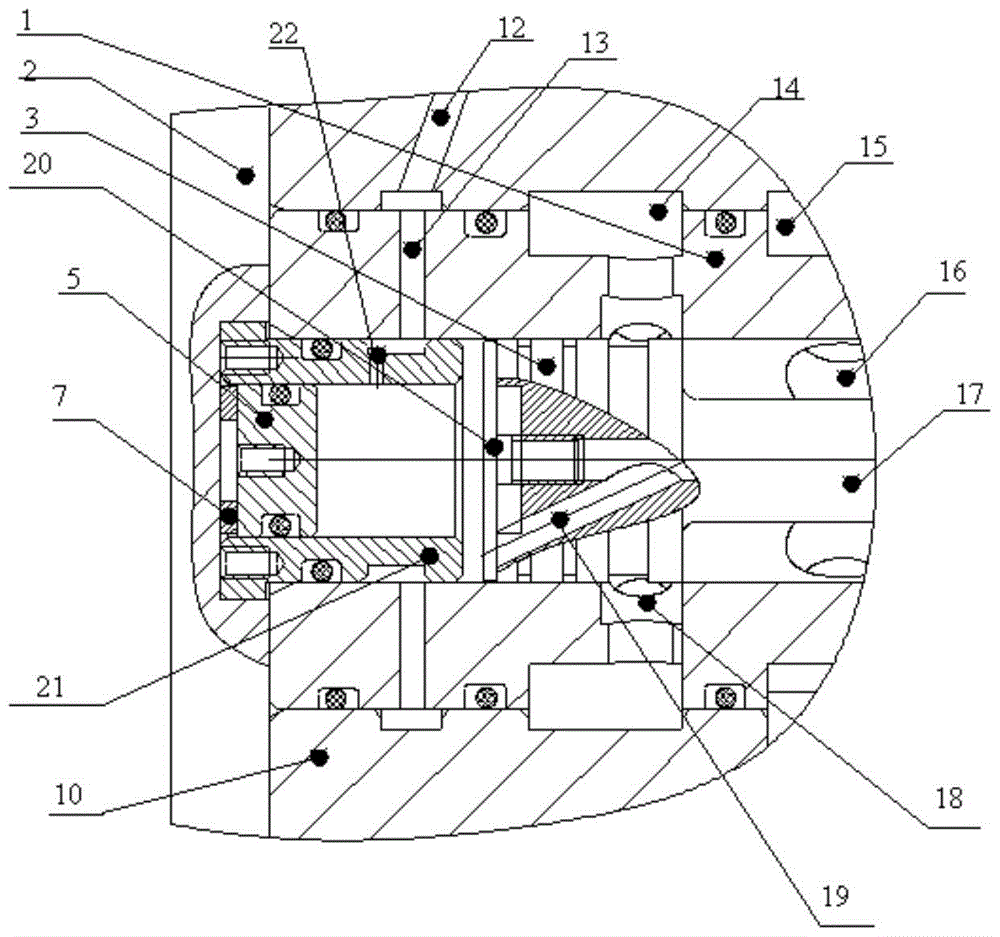

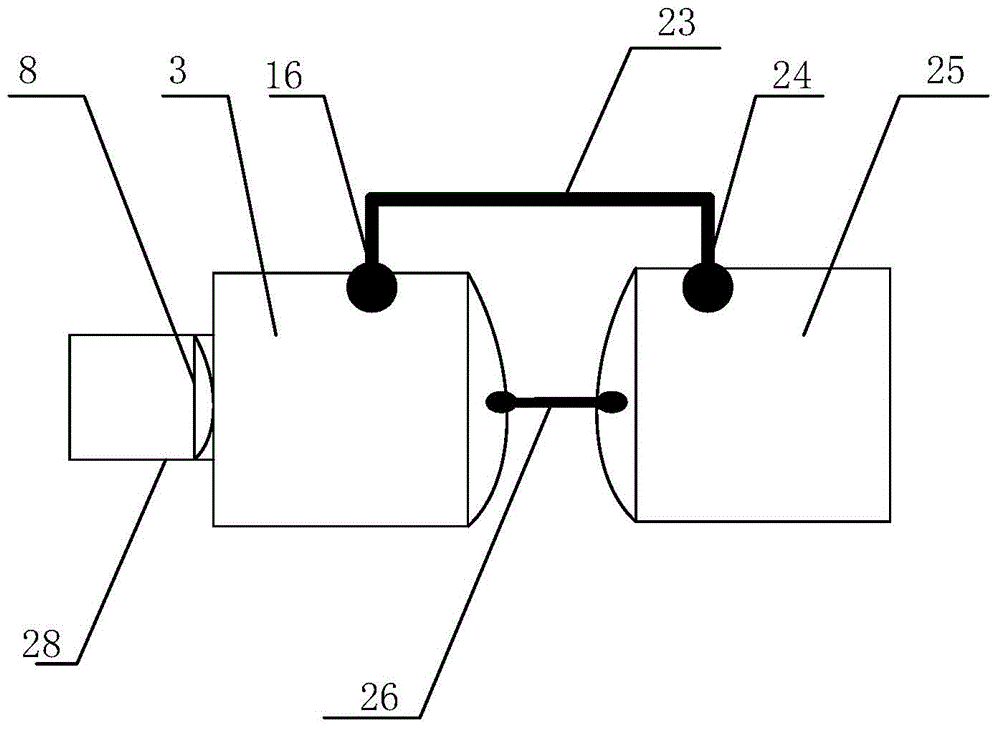

[0021] Such as figure 1 As shown, a servo valve A provided by the present invention with a split power stage servo valve debugging device includes a control oil system 27 without a small spool, a main spool 3, a main spool control chamber 16, a second main valve Core control cavity 24 , second main valve core 25 , control cavity communication channel 23 , internal leakage channel 26 . The control oil in the control oil system 27 without a small spool directly acts on the left end of the main spool 3 . The main spool 3 communicates with the second main spool 25 through an internal leakage passage 26 . The main spool 3 is provided with a main spool control cavity 16, the second main spool 25 is provided with a second main spool control cavity 24, and the gap between the main spool control cavity 16 and the second main spool control cavity 24 The outside communicates with the control chamber communication channel 23, and the control chamber communication channel 23 can be opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com