Multistage rotation dust washout testing device for aviation engine blade

An aero-engine and test device technology, which is applied in the direction of testing wear resistance, etc., can solve the problems of inability to adjust, accurately control the sand and dust flow and the humidity of the sand and dust environment, without an experimental platform and an assessment device, and achieves convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

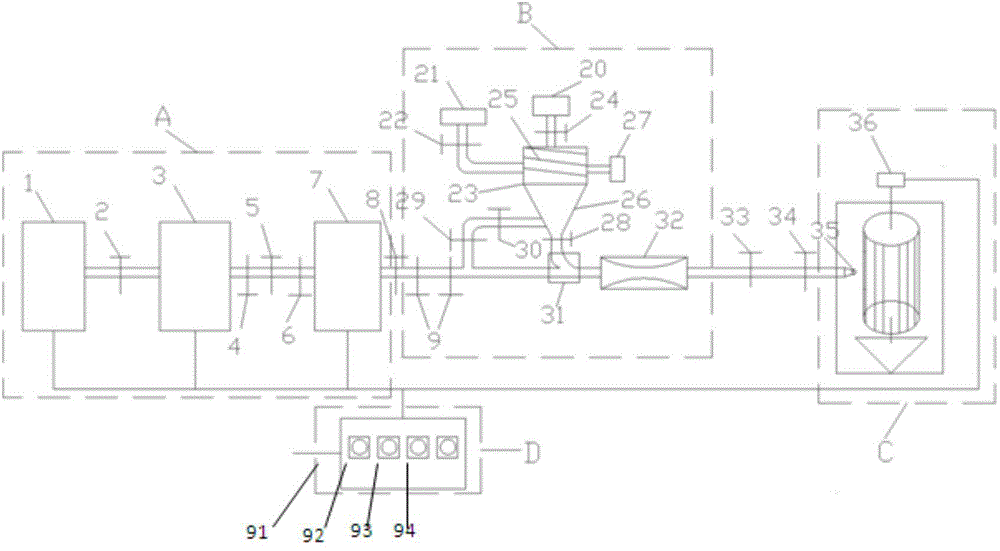

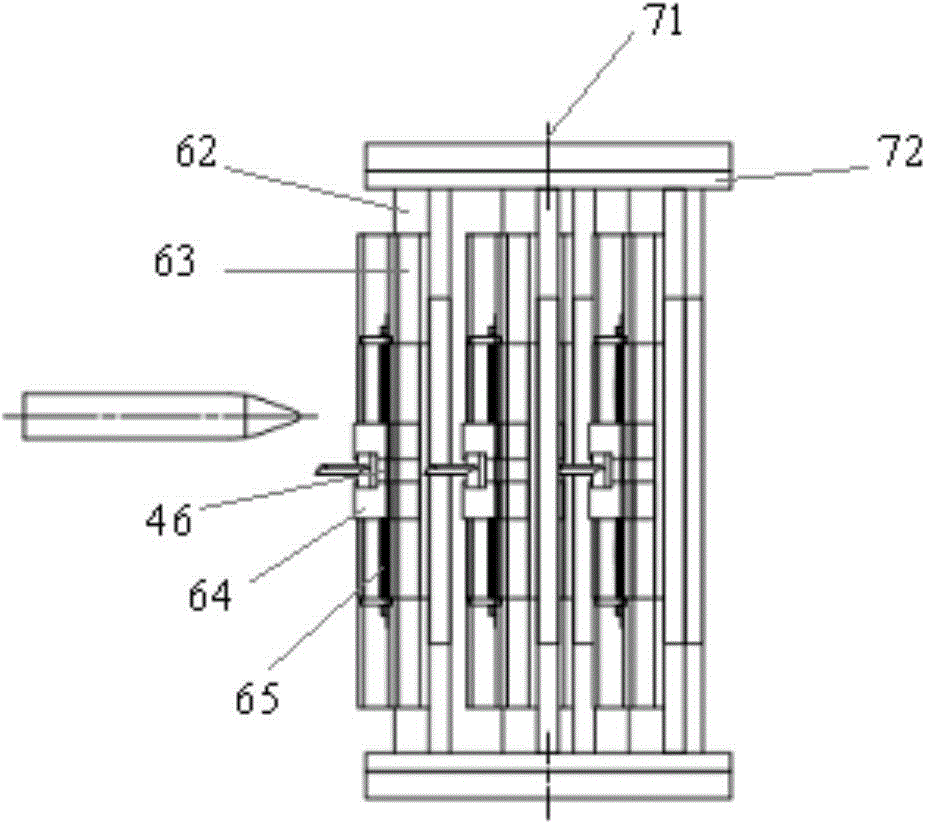

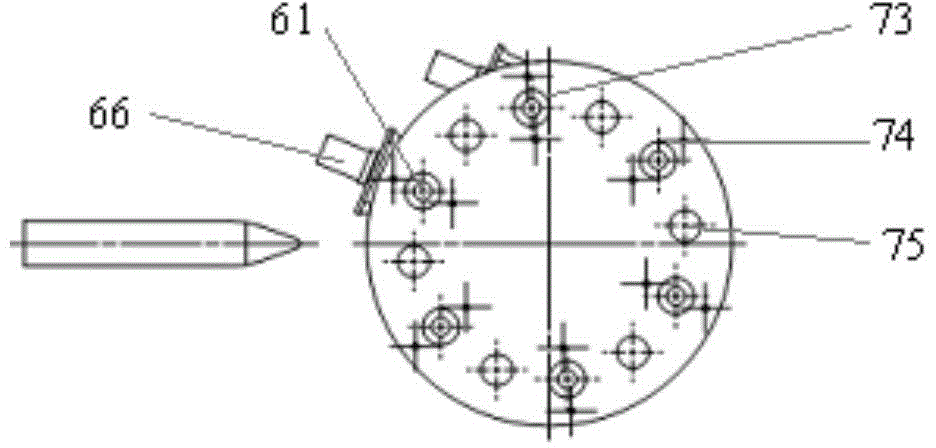

[0036] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 The aeroengine blade multi-station rotary sand and dust erosion test device of the present invention includes a high-pressure air source, a sand and dust supply and gas mixing device, a test system and a control platform, a motor 36 and a device for installing the test piece 66 Test piece installation device; the output shaft of the motor 36 is connected with the test piece installation device; the high-pressure air source includes an air compressor 1, a high-pressure gas storage tank 3, a gas pressure gauge 4 and an air dryer 7, and the air compressor The outlet of 1 is connected with the inlet of high-pressure gas tank 3, and the outlet of high-pressure gas tank 3 is connected with the inlet of air dryer 7 through gas pressur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap