A flatness compensation system and method for a compact field plane scanning frame

A plane scanning and compensation system technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as difficulty in ensuring compensation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

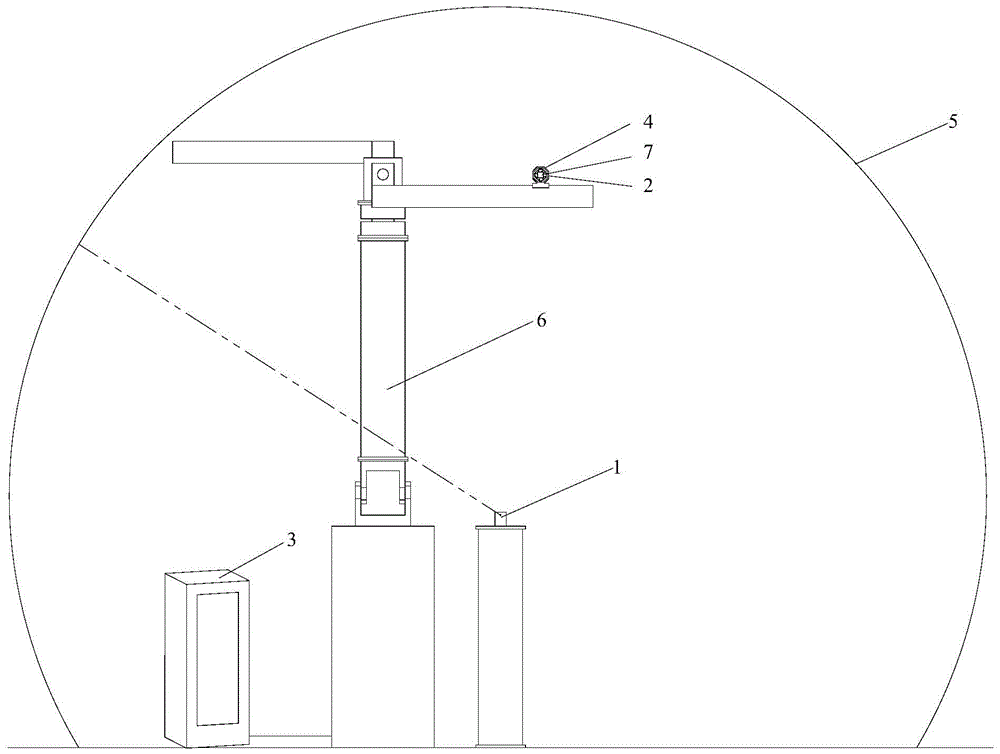

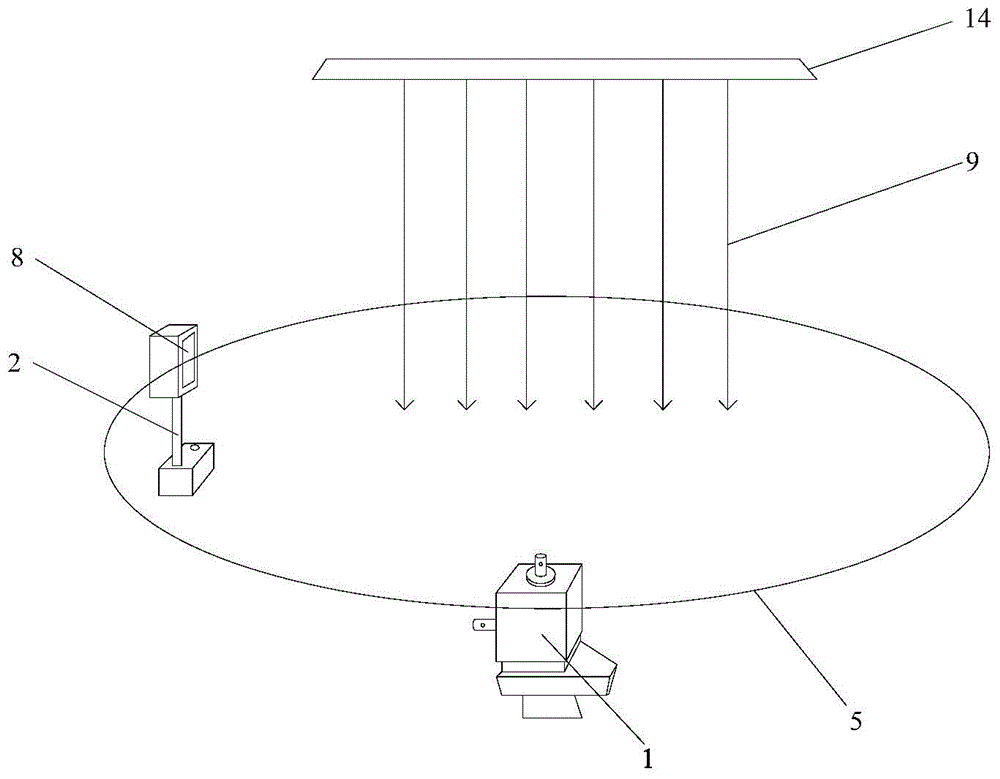

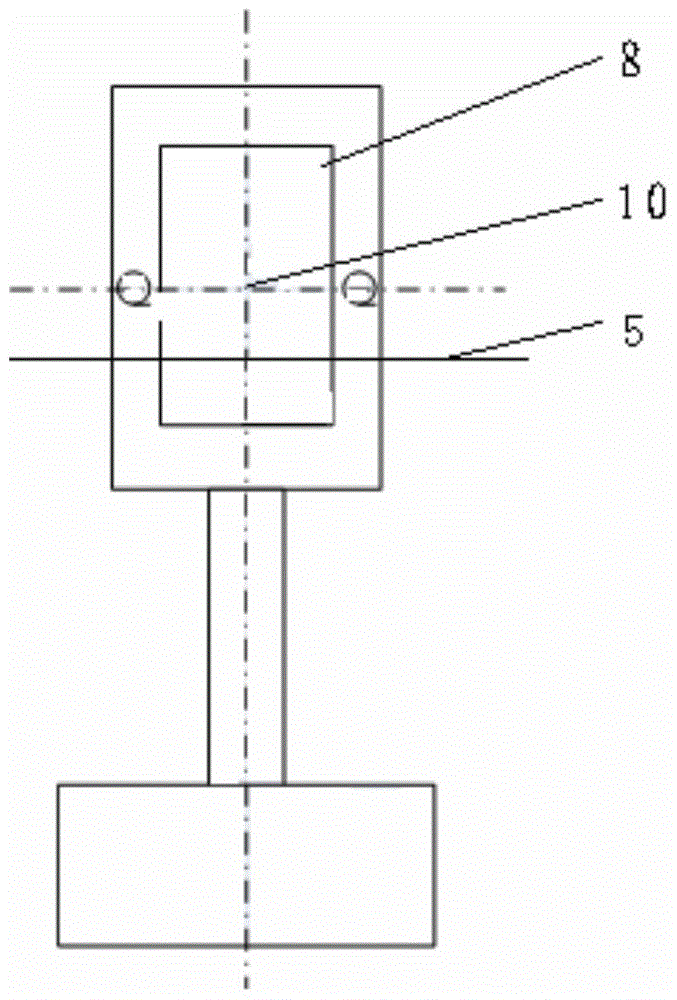

[0046] Such as figure 1 As shown, the flatness compensation system of the compact field plane scanning frame provided by this embodiment includes a laser plane emitting device 1, a position sensitive detector PSD2, a controller 3 and a servo compensator 4, and the connection relationship and working method are as follows:

[0047] The laser plane emitting device 1 is fixed on the ground, and it rotates itself so that the emitted laser beam generates a laser plane 5, and the laser plane 5 is used as a reference plane.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com