CSP swing section wheel surface automatic lubrication device

A technology of automatic lubrication and swinging section, applied in the field of steel rolling equipment, can solve the problems of environmental pollution, adhesion of wheels and guide rails, accelerated wheel and guide rail damage, no supplementary grease, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

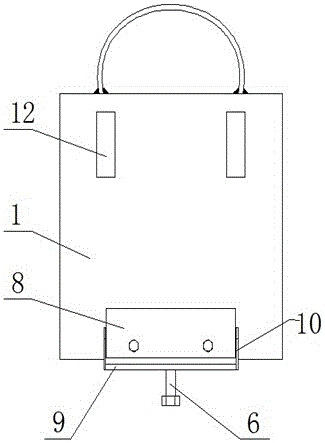

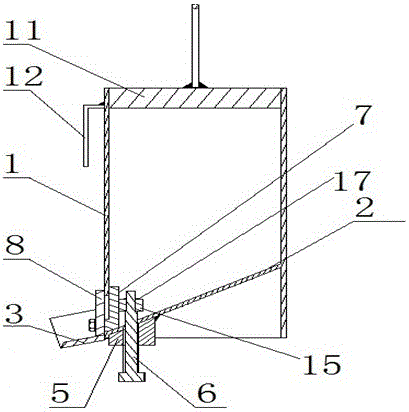

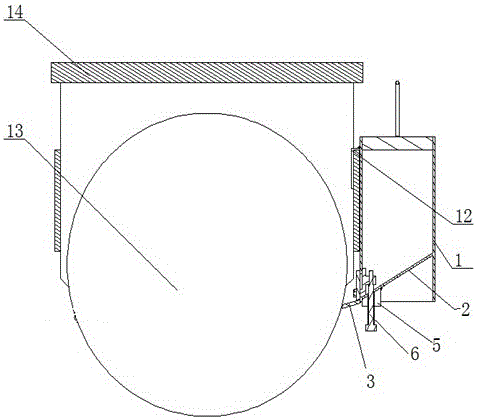

[0020] figure 1 , figure 2 , Figure 4 and Figure 5 It shows that the composition of the present invention includes a grease tank 1, an inner deflector 2, an outer deflector 3, a threaded lifting block 5, an adjustment screw 6, an inner oil adjustment plate 7 and an outer oil adjustment plate 8, and the inner deflector 2 is fixed on the inner wall of the grease tank 1, the angle between the inner deflector 2 and the bottom plate of the grease tank 1 is an acute angle, the side wall of the grease tank 1 is provided with a square oil hole 4, and the bottom of the oil hole 4 is located at the lower level of the inner deflector 2 At the junction of the edge and the side wall of the grease tank 1, the outer deflector 3 is composed of an outer deflector bottom plate 9 and two parallel outer deflector side plates 10, and one side of the outer deflector bottom plate 9 is connected to the grease tank 1 The bottom of the outer wall oil hole 4 is fixed, and the angle between the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com