A stator turning over tooling

A technology of turning over and tooling, applied in the directions of transportation and packaging, load hanging components, etc., can solve problems such as damage to the embedded stator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

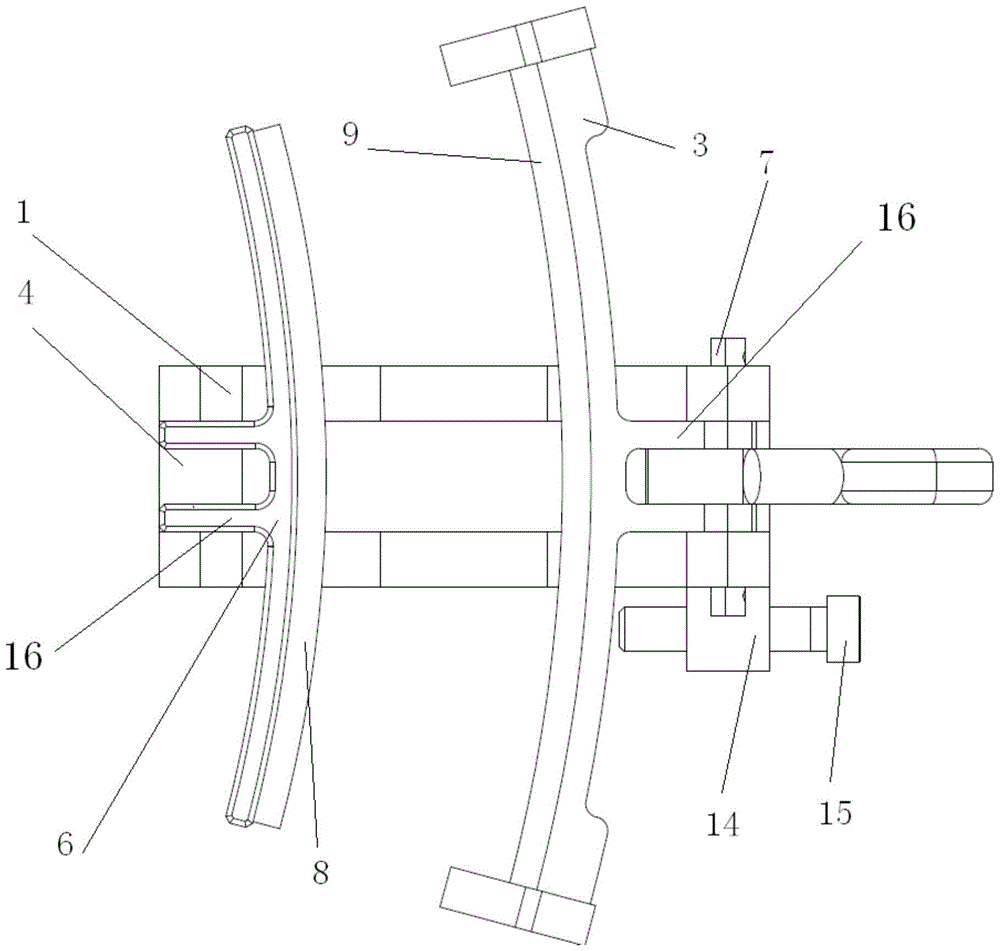

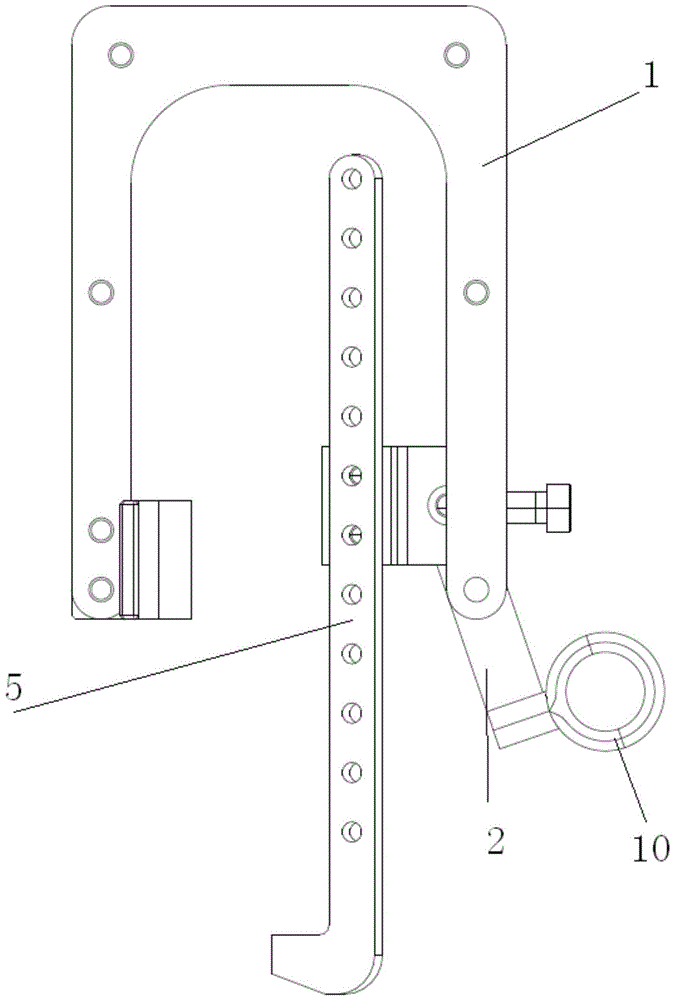

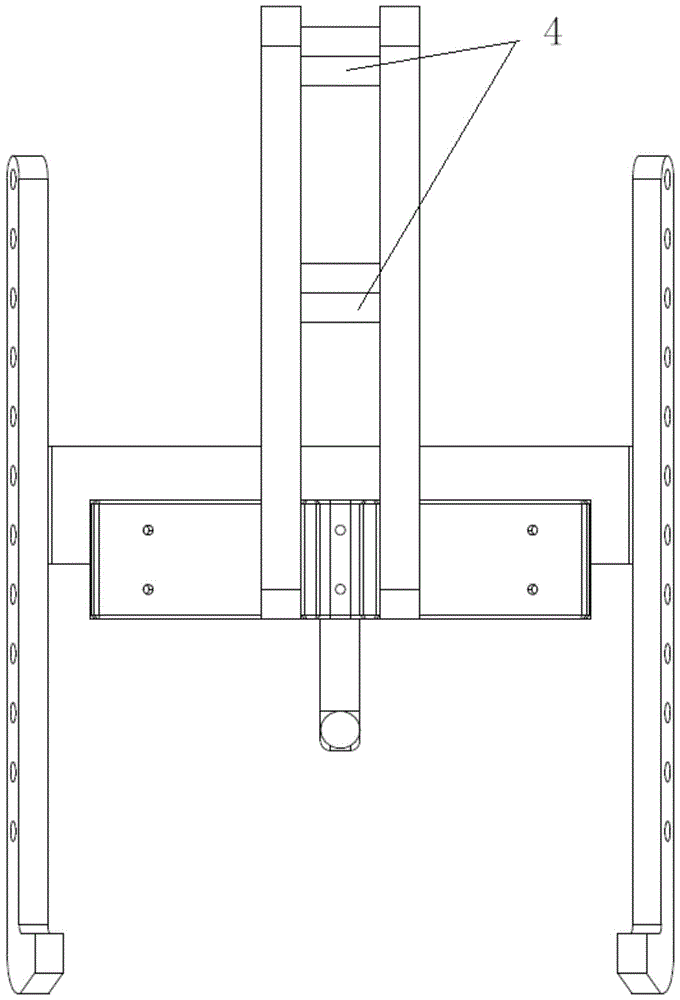

[0027] Such as Figure 5 As shown, put the tooling vertically on the wire-embedding stator 12, make the inner clamping block 6 and outer clamping block 3 of the tooling be placed between the inner and outer walls of the wire-embedding stator 12, and adjust the suspension according to the height of the wire-embedding stator. Then use the hook portion 50 of the suspension hook 5 to clamp the very small end face that can only be used at the lower end of the embedded wire stator, and then use the bolt 15 to withstand the outer diameter clamping block 3, pre-clamp, and place the tooling to fall off.

[0028] The driving hook hooks the suspension ring 10, so that the suspension rope is vertical to the ground 11 and slowly hoisted. Since the rotating shaft 7 is the center, the suspension ring 10 and the outer diameter clamp block 3 form a lever principle, so that when the suspension ring 10 is lifted upwards, the outer diameter clamp Block 3 is pressed down, and outer diameter clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com