Control method of auxiliary turn-over system

A control method and turning technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as low efficiency and product surface damage, and achieve the effect of ensuring efficiency and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

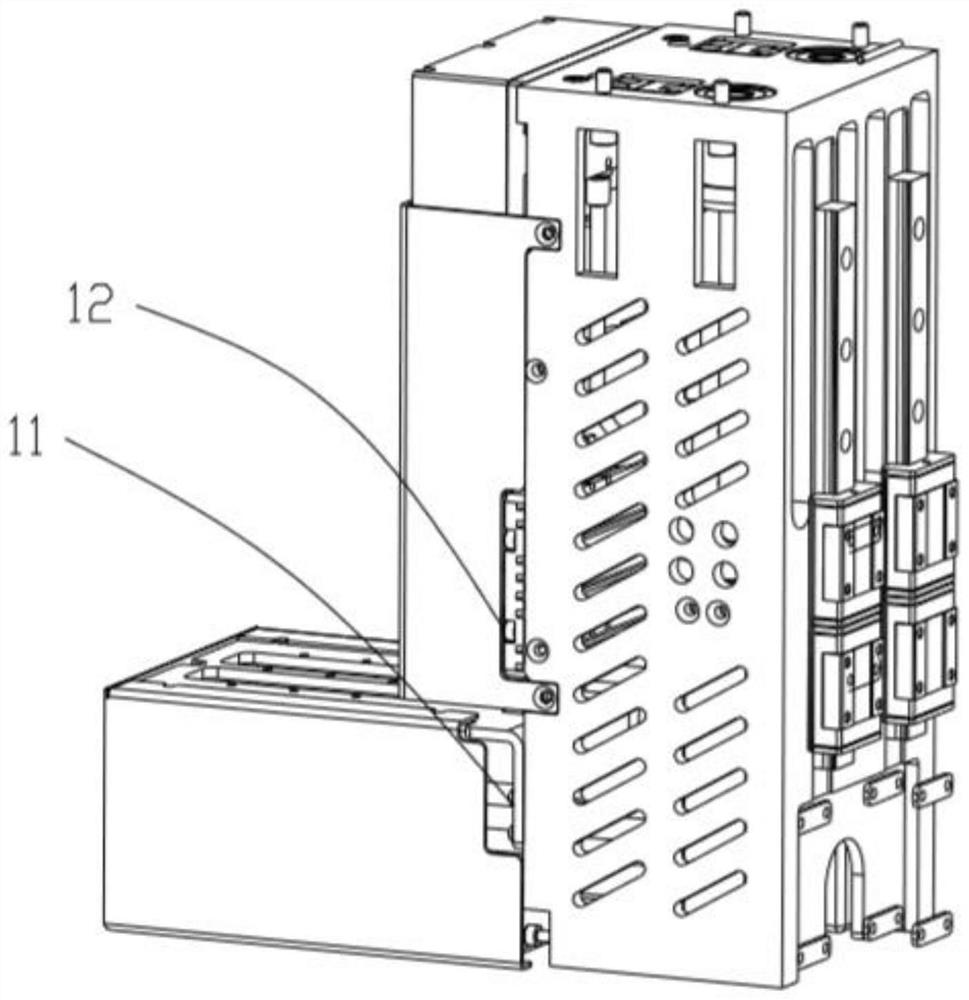

[0036] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

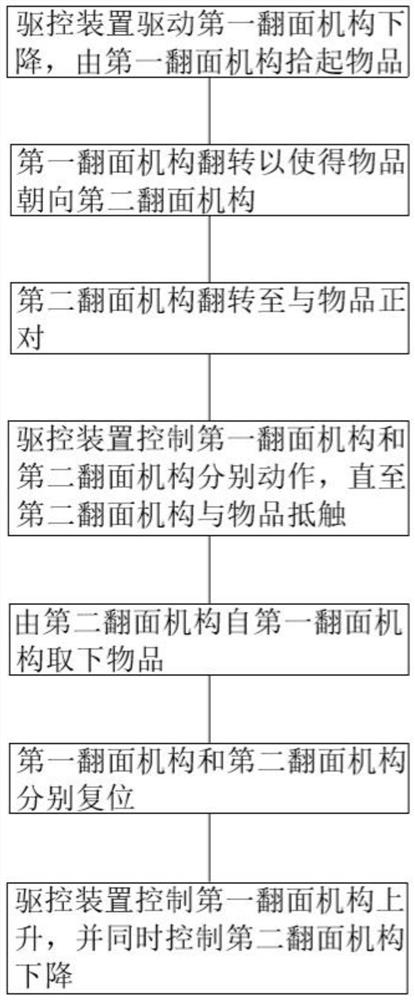

[0037] A control method for an assisted turning system provided by the present invention comprises the following steps:

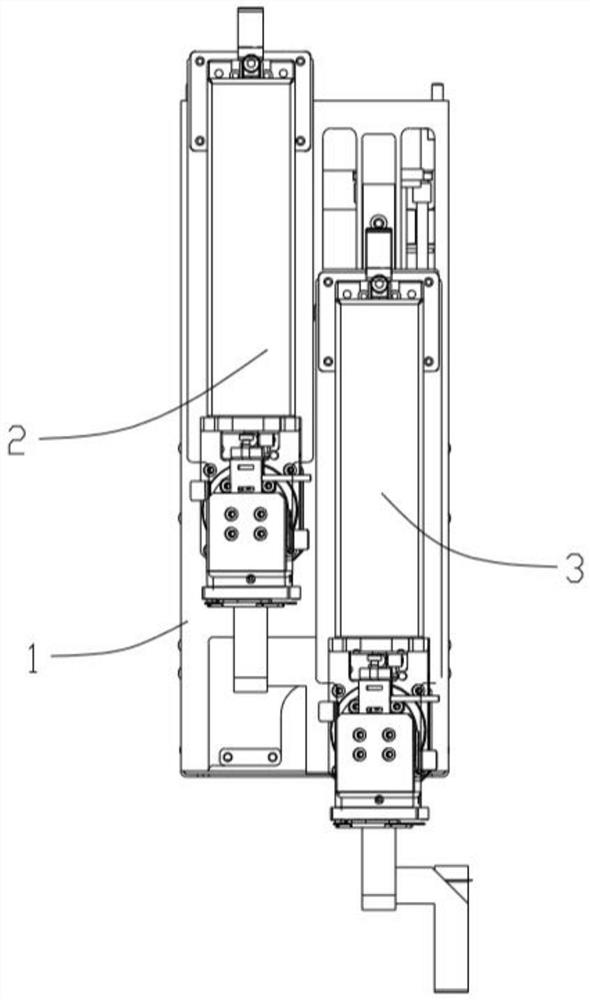

[0038] A. The drive control device 1 drives the first turning mechanism 2 to descend, and the first turning mechanism 2 picks up the item;

[0039] B. The first turning mechanism 2 turns over so that the article faces the second turning mechanism 3;

[0040] C. The second turning mechanism 3 turns over to face the item;

[0041] D. The drive control device 1 controls the first turning mechanism 2 and the second turning mechanism 3 to act separately until the second tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com