Core segment rod and rotary drilling rig drill rod having same

A technology of core section rods and drilling tools, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., and can solve problems such as the breakage of the joint of the drilling tool, the reduction of the service life, and the drop of the drilling tool into the hole, so as to reduce the cross-sectional size, Effect of improving service life and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended invention purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

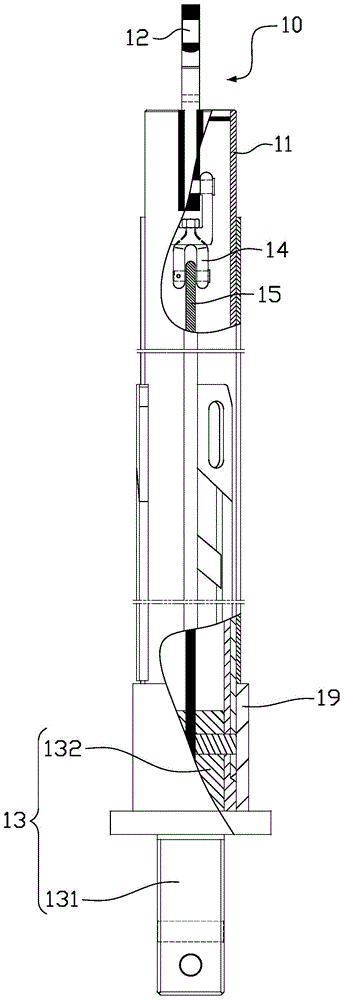

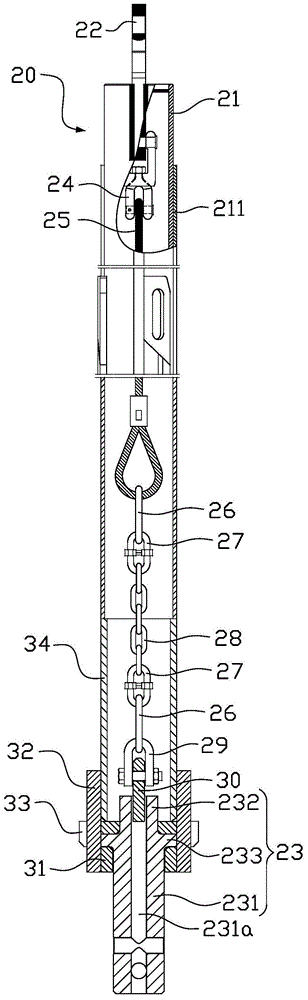

[0037] The drill rod of the rotary drilling rig provided by the present invention includes a core segment rod 20 and a multi-layer outer segment rod (not shown) located outside the core segment rod 20 .

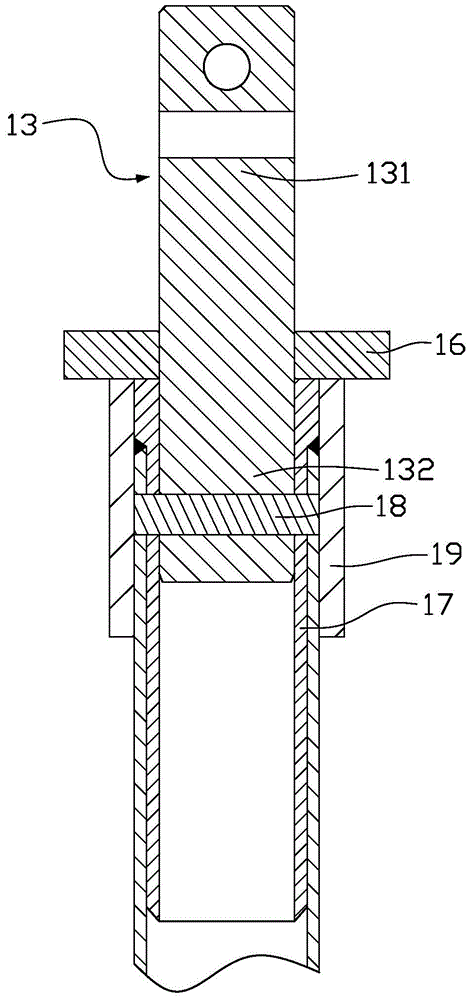

[0038] like image 3 As shown, the core segment rod 20 includes a core segment rod body 21 , a lifter connector 22 located at the upper end of the core segment rod 20 and a drilling tool connector 23 located at the lower end of the core segment rod 20 . The outside of the core section rod body 21 is fixed with a plurality of outer keys 211 by welding, and each layer of outer section bars except the outermost layer of the outer section bar includes an inner key located on the inner side of the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com