An online calibration method for gas dispensers based on a hand-held calibration device

A calibration device and calibration method technology, which can be applied to container discharge methods, container filling methods, equipment loaded into pressure vessels, etc., and can solve problems such as cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

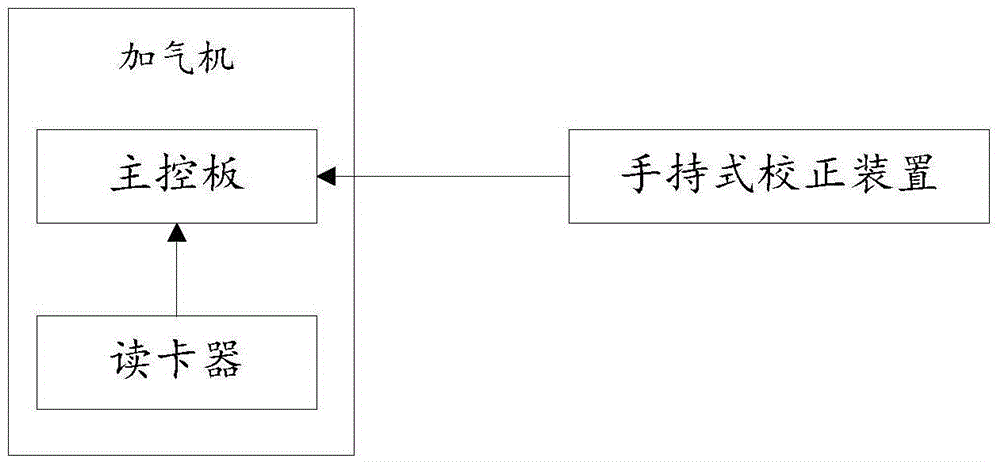

[0017] Embodiment 1. An online calibration system for gas dispensers based on a hand-held calibration device. Combine below figure 1 The system provided in this embodiment will be described in detail.

[0018] see figure 1 , the system provided in this embodiment includes a hand-held calibration device and an air dispenser electrically connected to the hand-held calibration device. In this embodiment, the displayed gas filling capacity of the dispenser (i.e. the standard gas filling capacity measured by the gas dispenser) and the standard gas filling capacity can be expressed by a functional relationship: standard gas filling capacity = K * display gas filling Quantity + A, among them, K>0, K is called the correction coefficient, and A is called the compensation coefficient. When there is an error between the displayed gas volume of the gas dispenser and the standard gas volume, the hand-held calibration device sets calibration parameters on it, wherein the calibration para...

Embodiment 2

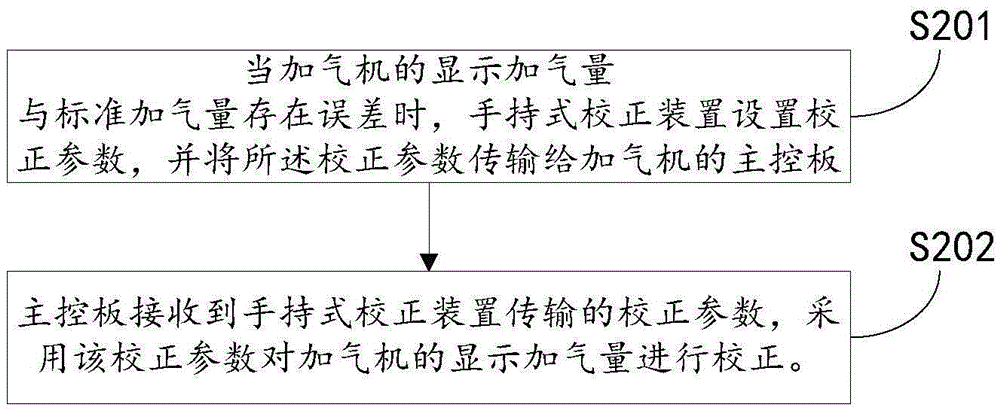

[0022] Embodiment 2. An online calibration method for gas dispensers based on a hand-held calibration device. Combine below figure 2 The method provided in this embodiment will be described in detail.

[0023] see figure 2 , S201. When there is an error between the displayed gas volume of the gas dispenser and the standard gas volume, the hand-held calibration device sets calibration parameters and transmits the calibration parameters to the main control board of the gas dispenser.

[0024] Specifically, when there is an error between the displayed gas filling amount of the gas dispenser and the standard gas filling amount, the hand-held calibration device sets calibration parameters on it, wherein the calibration parameters in this embodiment mainly include calibration coefficients and compensation coefficients , and transmit the set correction parameters to the main control board of the dispenser. It should be noted that, in order to ensure the safety of the handheld ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com