Spring delivery mechanism

A conveying mechanism and conveyor belt technology, applied in the direction of online nets, other household appliances, household appliances, etc., can solve the problems of affecting the work of the meshing machine and the overturning of springs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

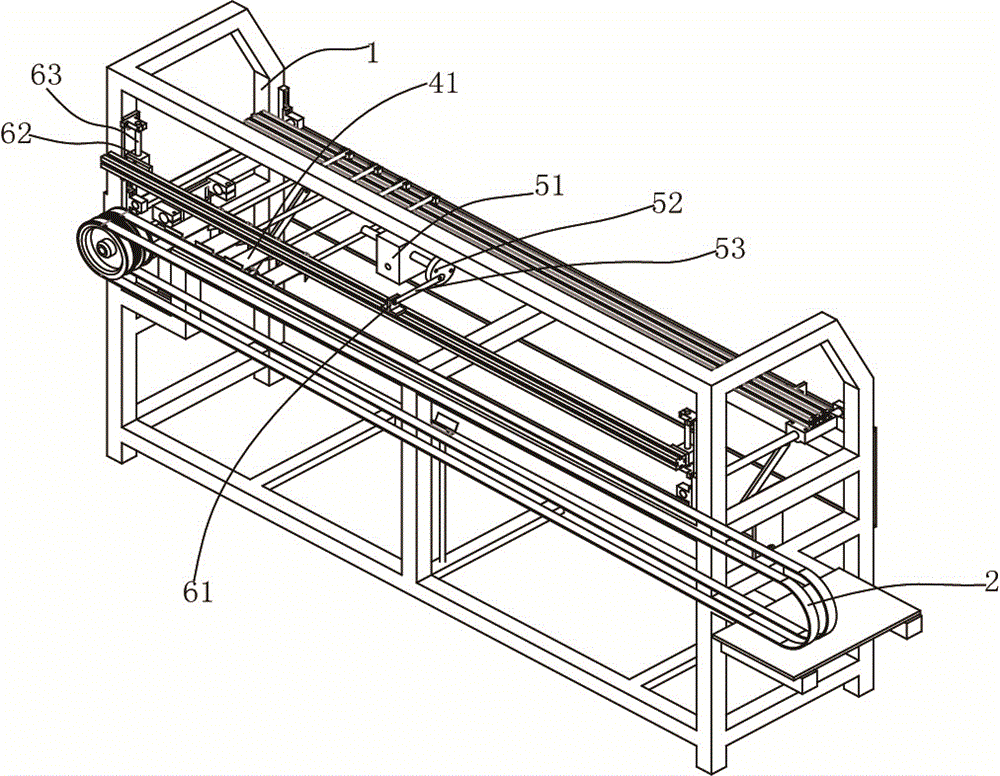

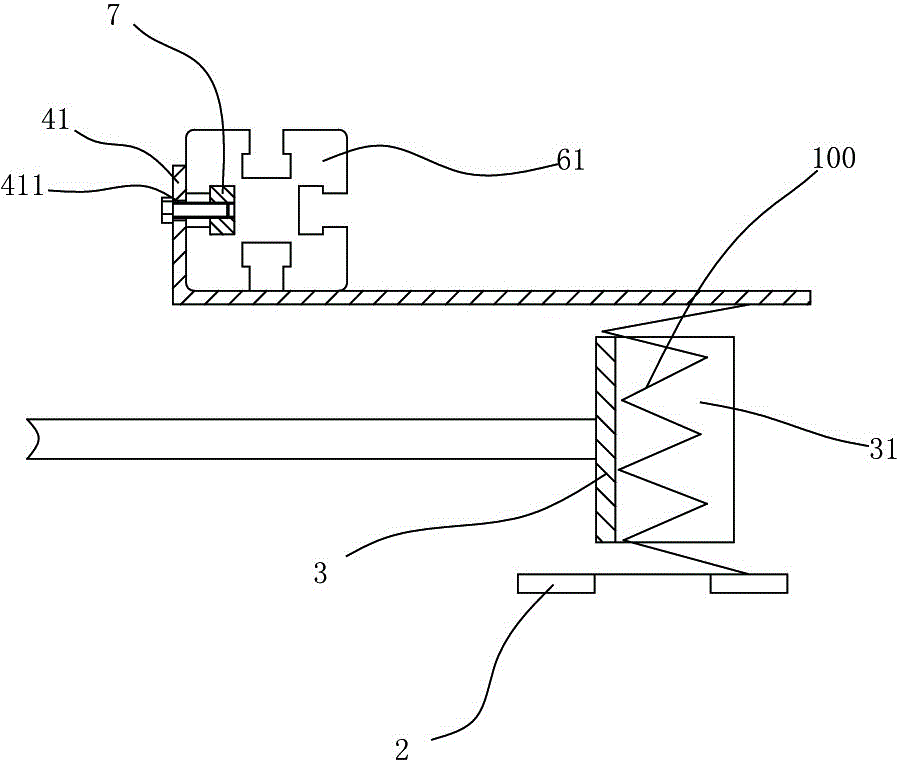

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 3 , The spring conveying mechanism includes a frame 1 and a magnetic conveyor belt 2, and the spring is adsorbed on the conveyor belt 2. The horizontal direction of the frame 1 is provided with a push plate 3 and a first driving device that drives the push plate 3 to move. The push plate 3 is provided with a groove 31. When the push plate 3 pushes the spring 100 to move towards the screen threading machine , at least two sides of the groove 31 are in contact with the spring 100 .

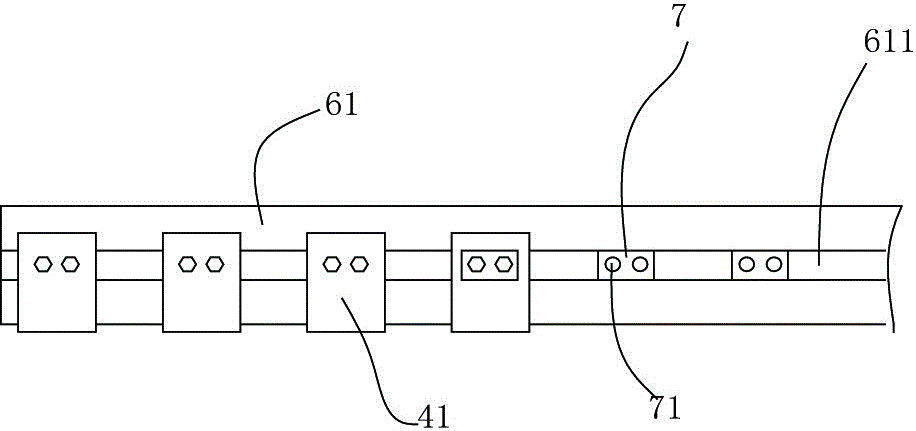

[0014] The vertical direction of frame 1 is provided with down-pressing mechanism, and described down-pressing mechanism comprises pressing plate 41 and the second driving device that drives pressing plate 41 to descend, and described second driving device comprises worm gear reduction mechanism 51, and described worm gear reduction mechanis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap