Anti-toppling cup sleeve

An anti-dumping and cup sleeve technology is applied in the field of anti-dumping cup sleeves, which can solve the problems of liquid splashing, breaking, and inconvenience in taking the cup body, and achieve the effects of easy taking, convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

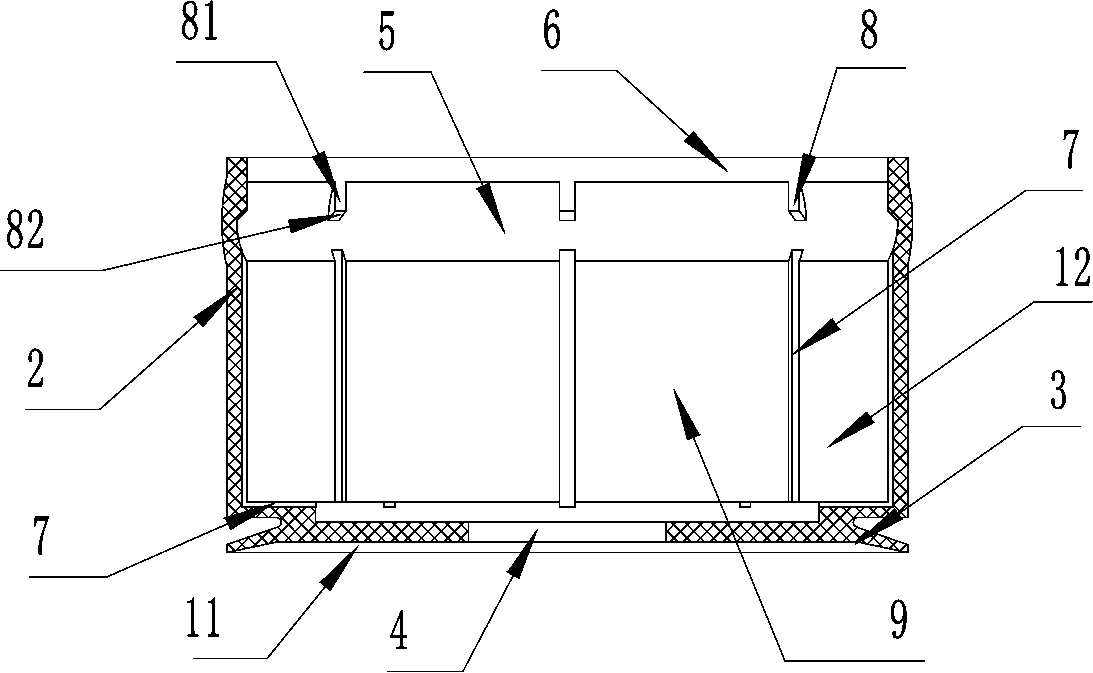

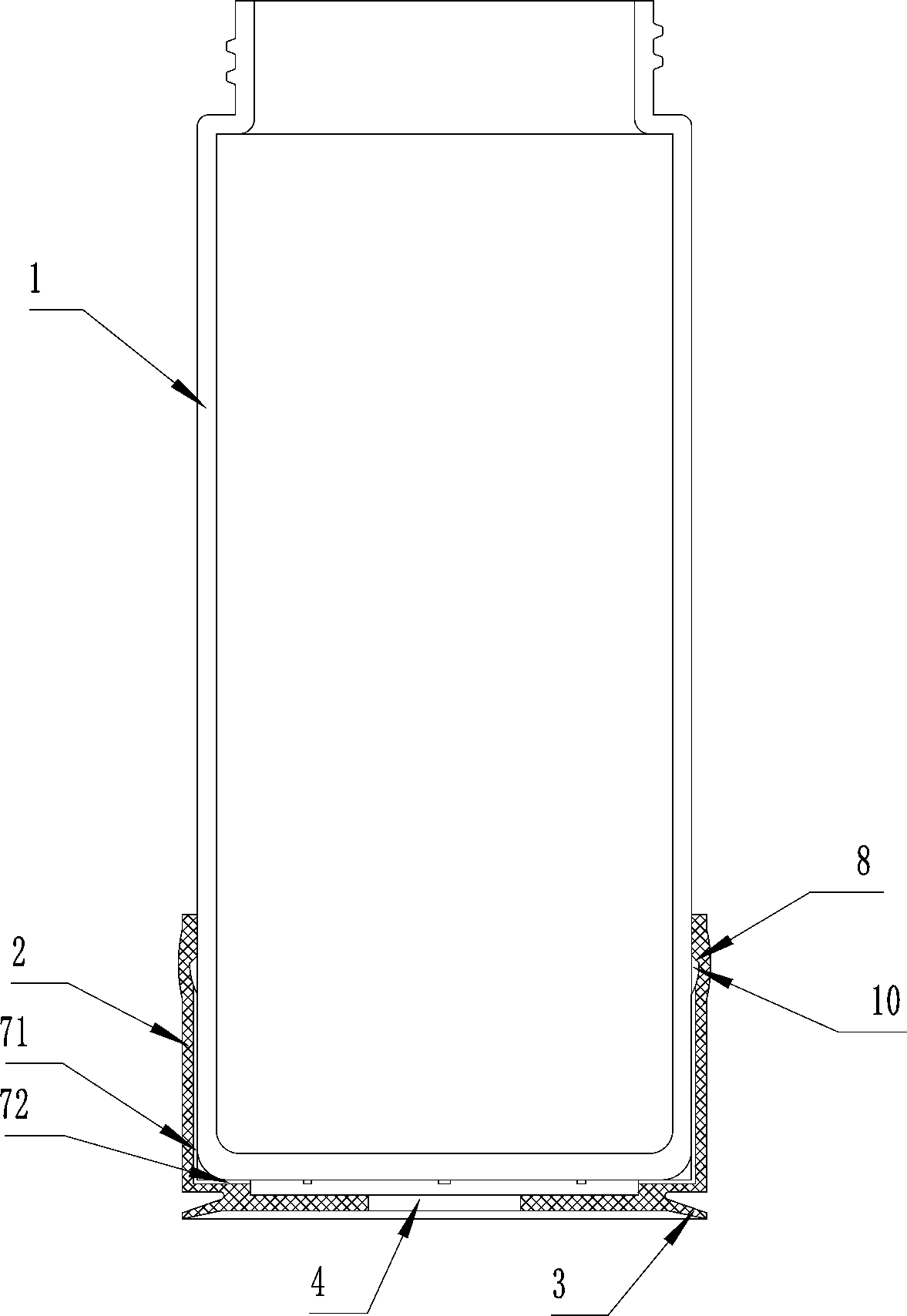

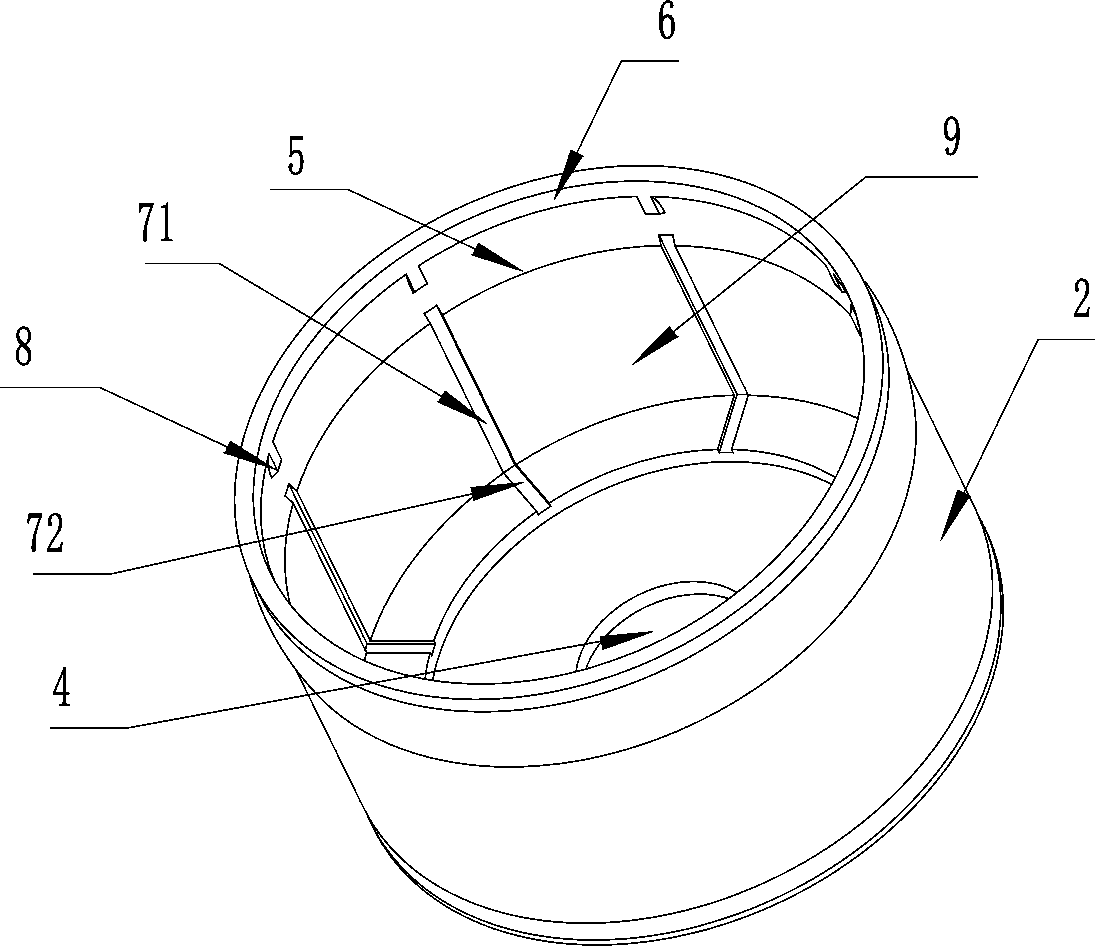

[0022] refer to Figure 1-3 As shown, it is the first embodiment of the present invention: an anti-tipping cup sleeve, including a cup 1 used in conjunction with it (the cup is selected in this embodiment, and it is also suitable for containers such as bottles in actual use). The sleeve 2 is cylindrical with an upper opening, the cup sleeve 2 is made of flexible silicone material, and a suction cup 3 is arranged below the cup sleeve 2, and the suction cup 3 has a through hole 4 communicating with the inside of the cup sleeve 2 , the upper inner surface 9 of the cup sleeve 2 is provided with a groove 5 horizontally surrounding the inner surface 9, the inner surface above the groove 5 is the first contact surface 6, the groove The inner surface below the 5 is the second contact surface 12, and the second contact surface 12 is provided with 8 ventilation grooves 7 connecting the groove 5 and the through hole 4, and the ventilation groove 7 is a straight line Arranged, the ring i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap