A lens automatic loading machine

An automatic feeding and lens technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of large floor space, inability to quickly replace products, and inability to continuously supply materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

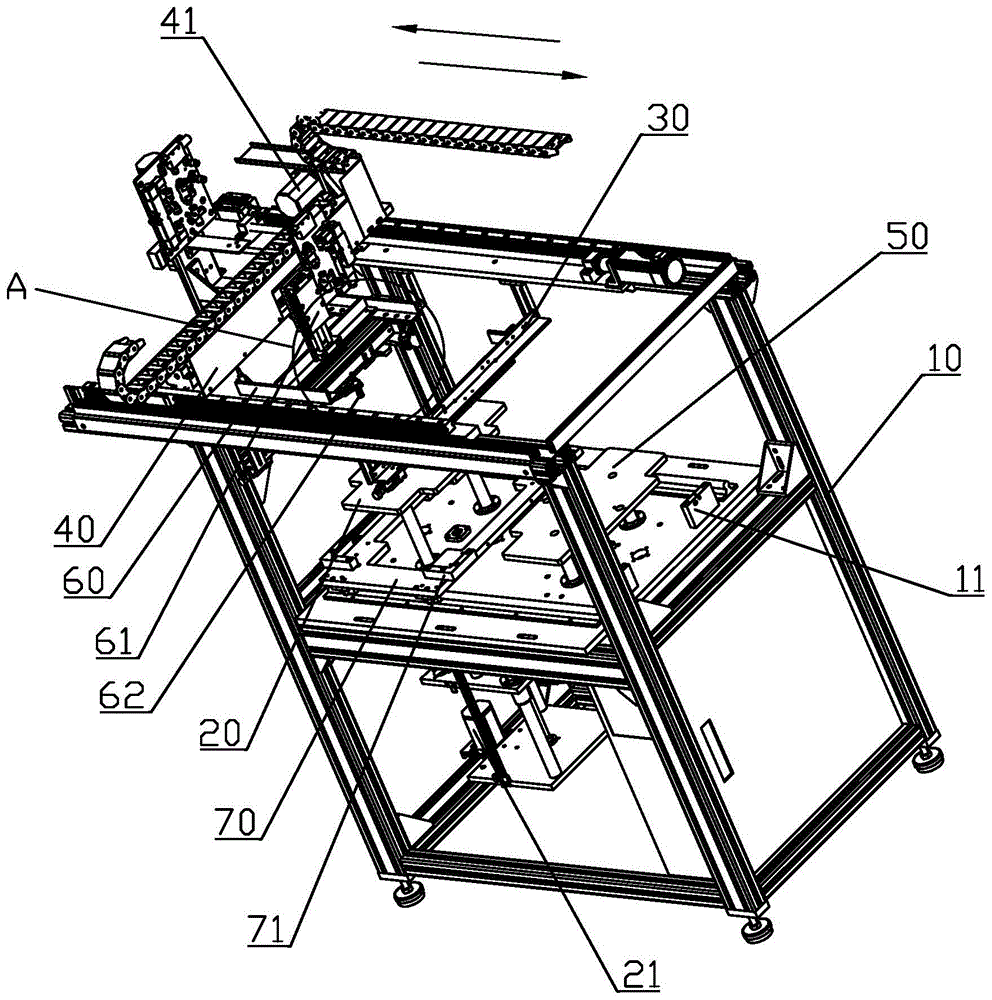

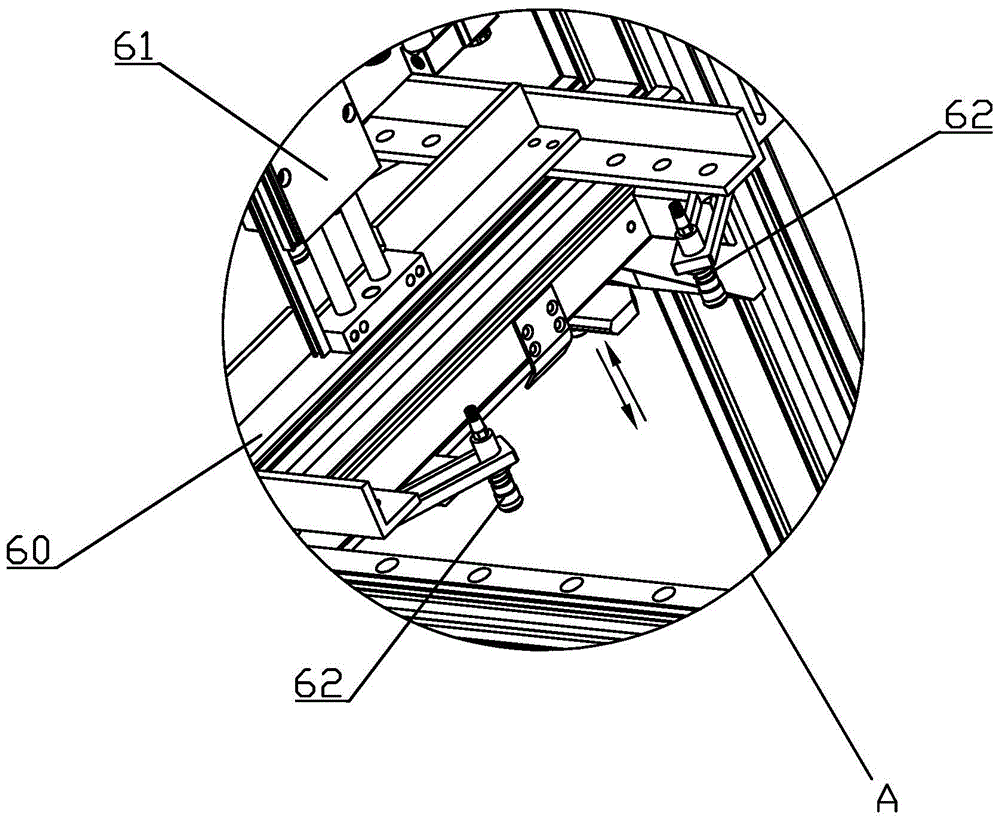

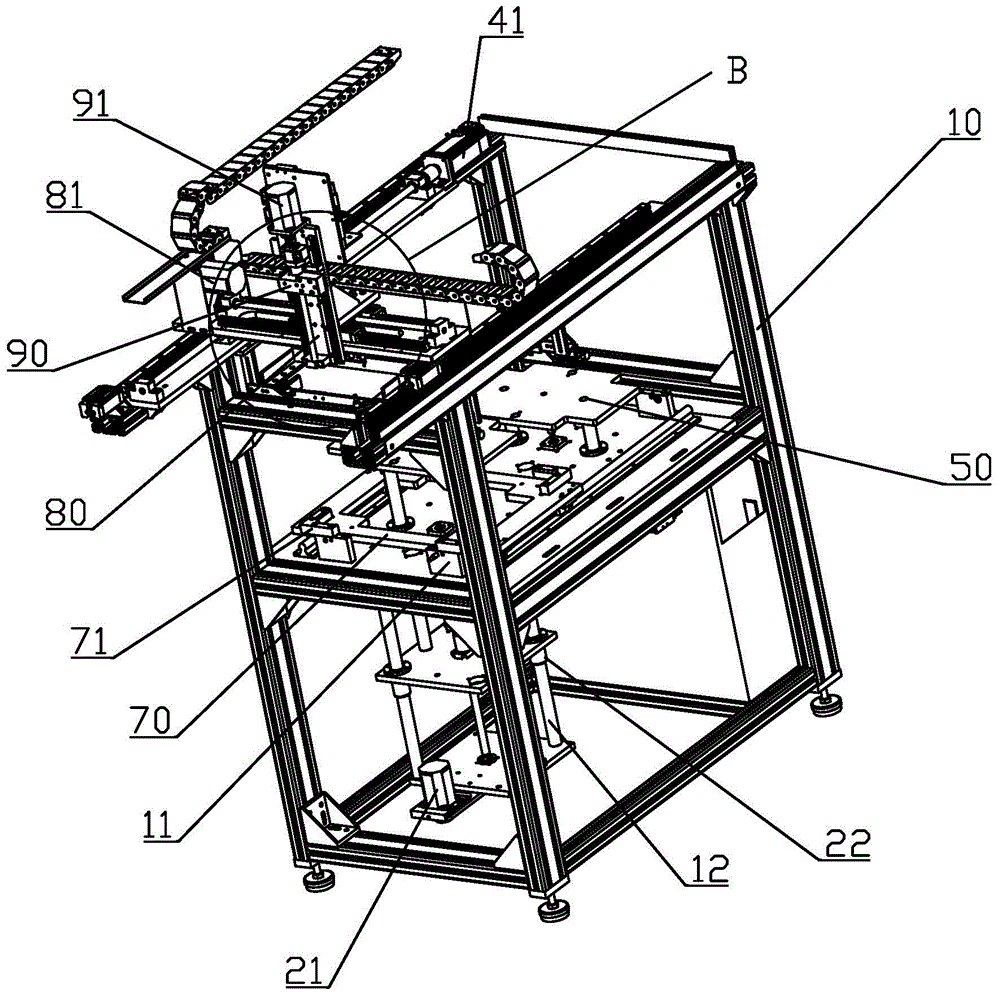

[0026] refer to Figure 1 to Figure 6 ( figure 1 The direction of the arrow in the paper is the left and right direction in this paper), an automatic lens loading machine, including a frame body 10, a frame body 10; a feeding table 20 is provided at the bottom of the frame body 10, and the feeding table 20 consists of a first Pushed by a driving device, it can move up and down, so that the stacked trays placed on it are sequentially raised to the pick-up position; a bracket 30 is provided above the feeding platform 20, and a number of telescopic brackets are arranged on the bracket 30. Supporting foot 31, when feeding platform 20 rises material tray to the position of taking material, this supporting foot 31 can stretch out to replace feeding platform 20 supporting material tray; The top of frame body 10 is provided with a walking support 40, and this walking support 40 is made A second driving device pushes and can move left and right. The walking frame 40 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com