Yarn winding mechanism

A winding mechanism and yarn technology, applied in the textile field, can solve the problems of discontinuous production process, reduce production efficiency, etc., and achieve the effect of improving production rate and avoiding time waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to illustrate the structural features and effects of the present invention more clearly, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

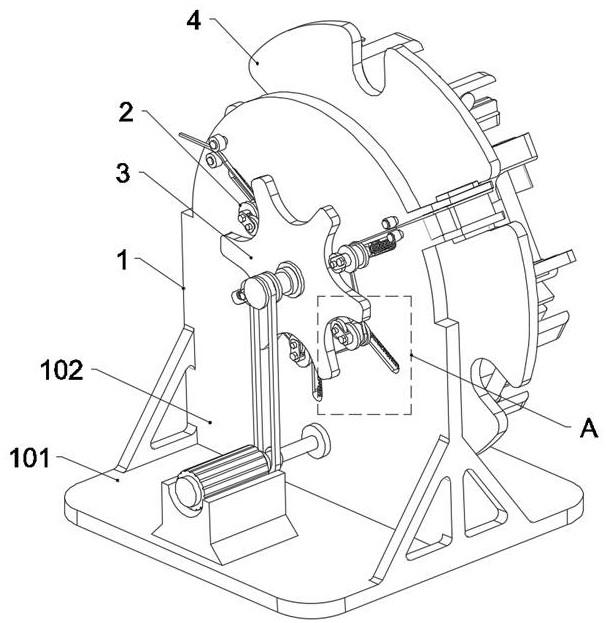

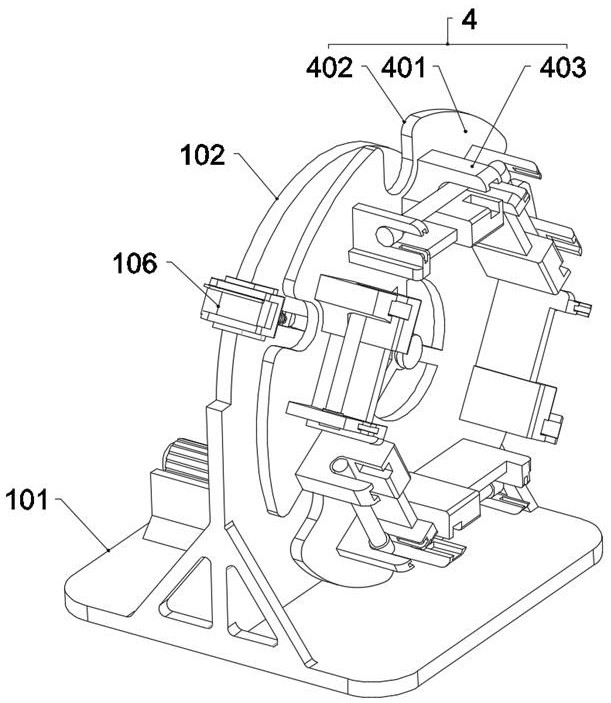

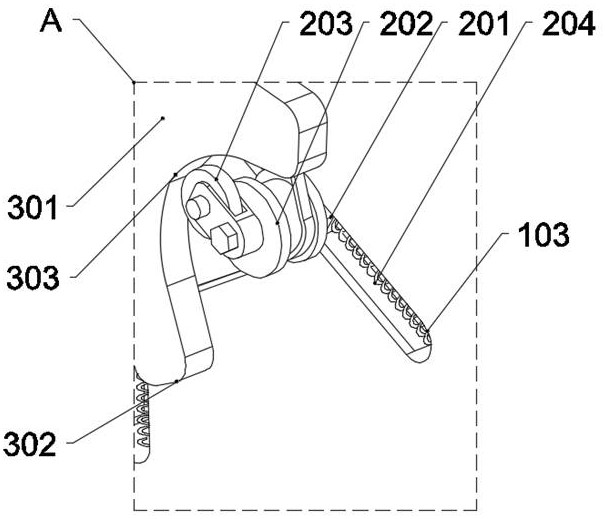

[0032] see Figure 1-Figure 5 , the yarn winding mechanism in an embodiment of the present invention includes a base plate assembly 1, the base plate assembly 1 includes a main base plate 101, a vertical plate 102 and a guide groove 103, and a vertical plate is fixedly assembled on the main base plate 101 102, the vertical plate 102 is provided with more than one guide groove 103 in the circumferential direction, and the guide grooves 103 all point to the same center of the circle; the wire storage wheel set 2, the wire storage wheel set 2 includes a sliding member 201, a wire winding Wheel 202 and roller 203, the sliding member 201 is slidably assembled in the guide groove 103, and more than one sliding member 201 is arranged on one side of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com