Paying-off damping device of paying-off machine

A technology of damping device and pay-off machine, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, can solve the problems of broken wires, difficult to control tension, fragile and conductors, etc., and achieves a simple overall structure, Improve the efficiency of disk replacement and the effect of long-lasting repeated service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

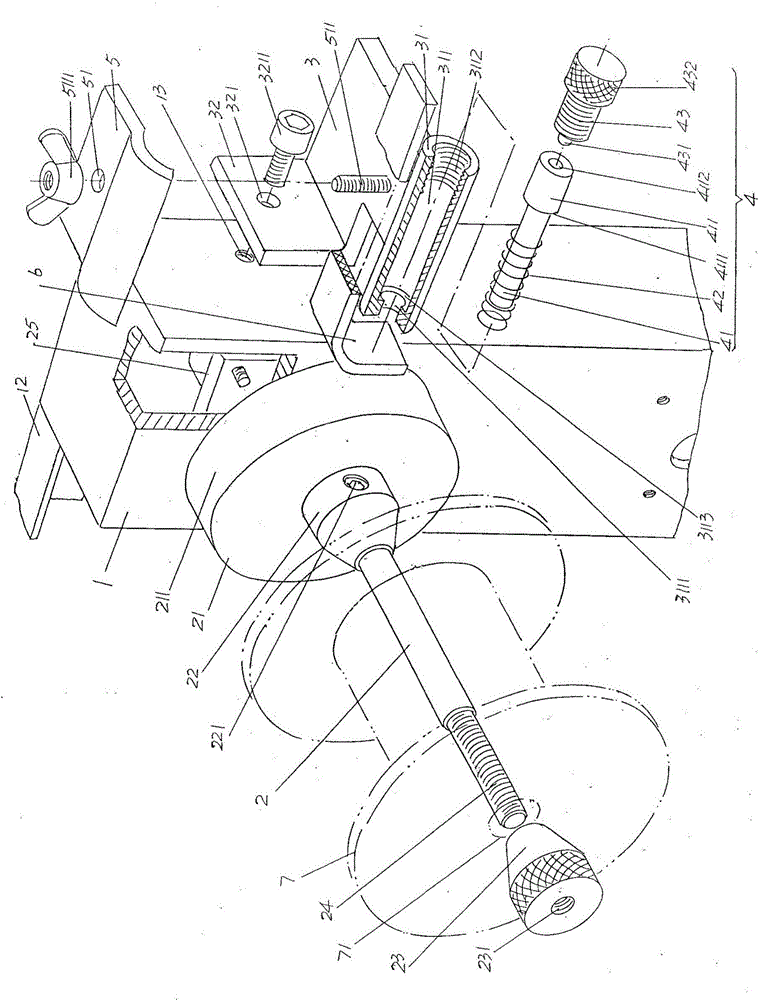

[0022] See figure 1 , provides a pay-off rack 1 belonging to the structural system of the pay-off machine; a pay-off shaft 2 for setting the pay-off reel 7, the rear end of the pay-off shaft 2 is rotatably supported on the pay-off rack through a bearing seat 25 1, and at the rear end of the pay-off shaft 2, a friction disc 21 and a pay-off disc rear support seat 22 are arranged. The position of the pay-off disc rear support seat 22 on the pay-off shaft 2 is located at the friction disc 21 and abuts against the friction disc 21, the front end of the pay-off shaft 2 is formed as a horizontal cantilever end, and is equipped with a front support seat 23 of the pay-off disc, and the aforementioned pay-off disc 7 is supported on the front and rear of the pay-off disc. Between the bearing seats 23,22.

[0023] According to professional knowledge, a plurality of pay-off shafts 2 can be set at intervals from top to bottom (also called bottom-up) in the height direction of the aforemen...

Embodiment 2

[0033] The figure is omitted, only the pay-off damping device of the present invention is transferred to the left side wall of the aforementioned pay-off rack 1, that is to say, the bracket 3 and the left side wall of the pay-off rack 1 are equivalent to the aforementioned screw holes 13. The hole is fixed. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com