Large-format special-shaped stumpage floor and manufacturing method thereof

A large-format, standing timber technology, applied in the direction of manufacturing tools, floors, building structures, etc., can solve the problems of poor continuity of floor boards, gaps, inconvenient paving, etc., to avoid waste, easy to operate, beautiful and soft structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

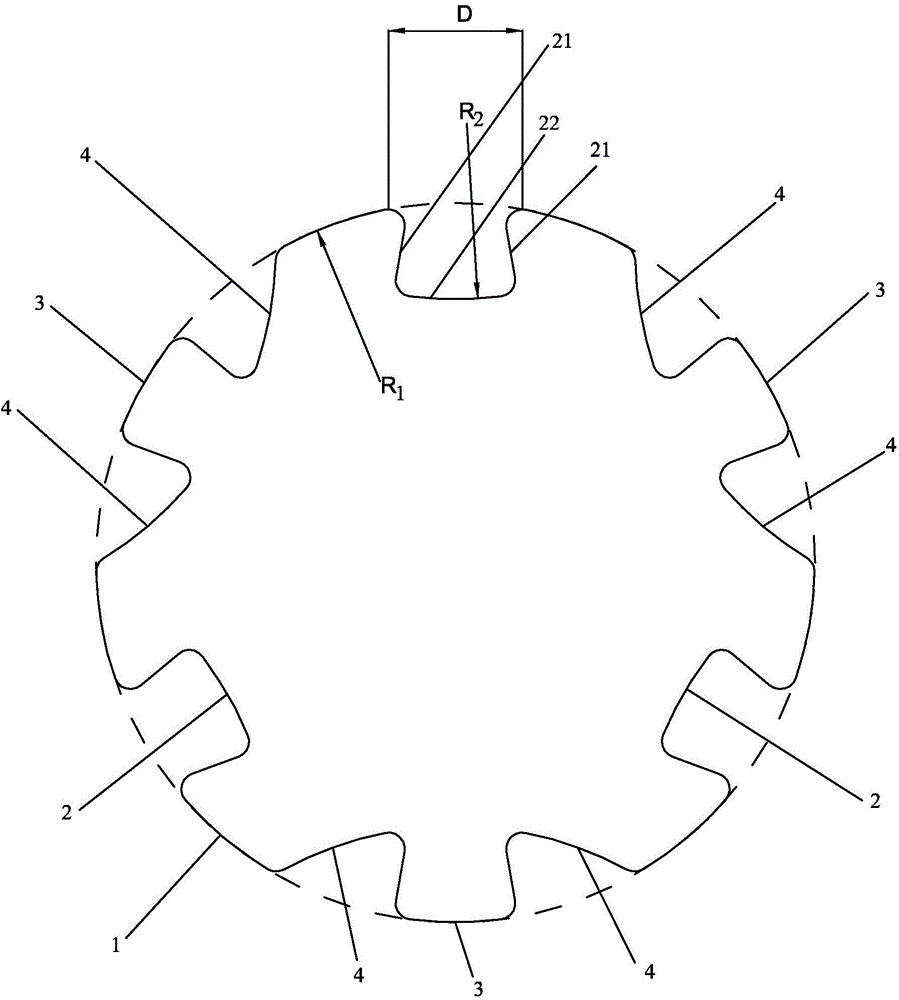

[0014] Specific implementation mode one: combine figure 1 To illustrate, in this embodiment, the large-format special-shaped standing wood flooring includes a main body 1, the outer edge of the main body 1 is circular in shape, and three grooves 2 are uniformly arranged on the main body 1, and D=1 / 3R 1 , the groove bottom of the groove 2 is wider than the notch, and the inner wall of the groove 2 is formed by connecting the planes 21 on both sides of the arc surface 22 and the arc surface 22 at the bottom, and the radius R of the arc surface 22 2 and body 1 outer edge radius R 1 Equal, there are two V-shaped grooves 4 between two adjacent grooves 2, a protrusion 3 is formed between adjacent V-shaped grooves 4, the shape of the protrusion 3 matches the shape of the groove 2, and the groove 2 The shape of the protruding part between the V-shaped groove 4 matches the shape of the V-shaped groove 4 . The arc surface 22 is connected to the plane 21 through a transition arc, and...

specific Embodiment approach 2

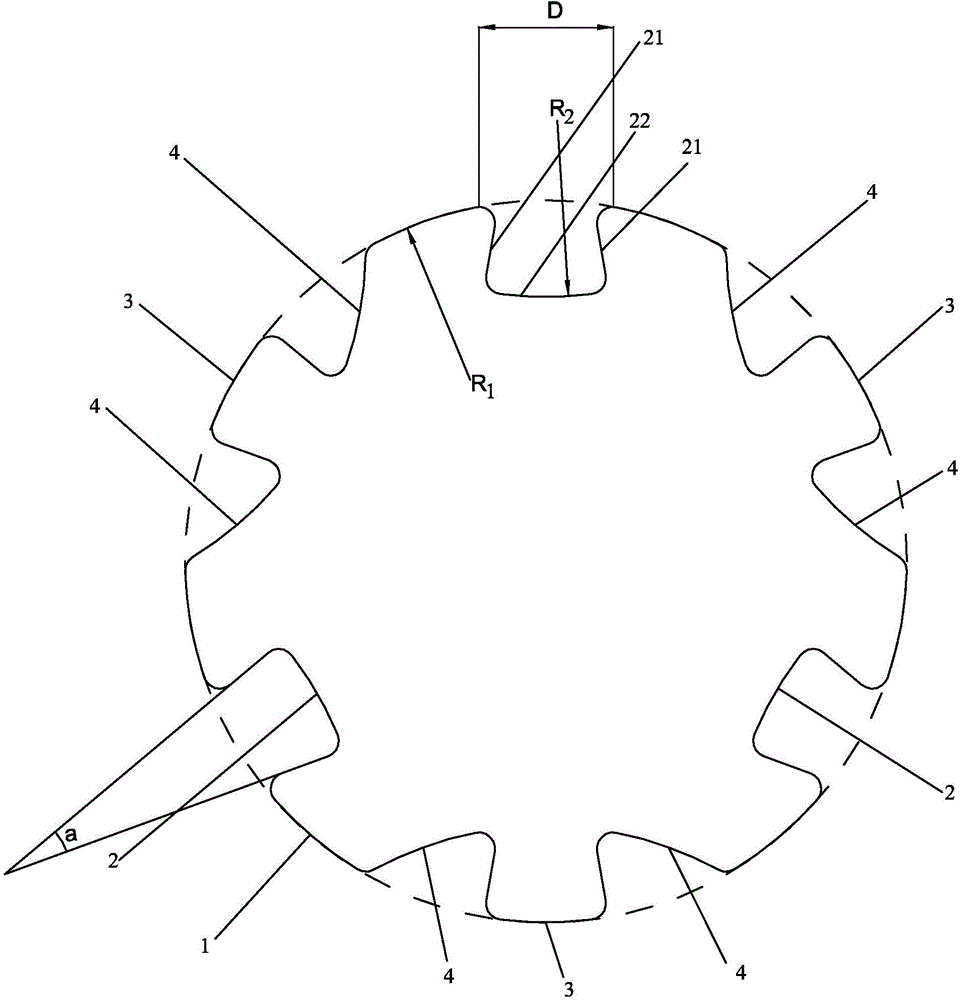

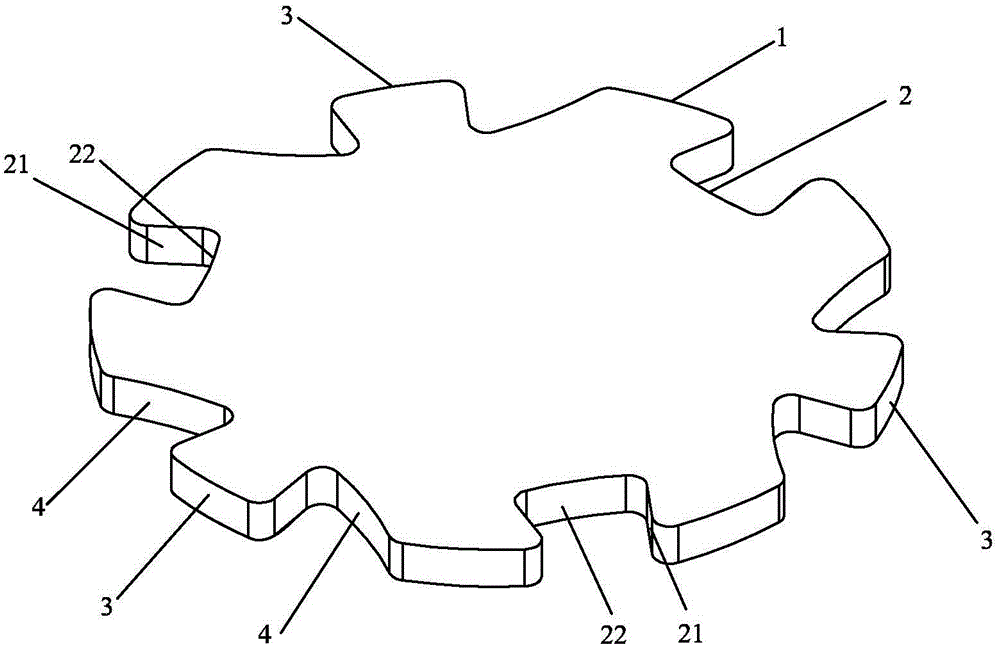

[0016] Specific implementation mode two: combination figure 2 , 3 4 and 4 illustrate that in this embodiment, the large-format special-shaped standing wood flooring includes a main body 1, the outer edge of the main body 1 is circular in shape, and three grooves 2 are uniformly arranged on the main body 1, and the groove bottom of the groove 2 is larger than The notch is wide, and the inner wall of the groove 2 is formed by connecting the bottom with the arc surface 22 and the planes 21 on both sides of the arc surface 22. The two planes 21 of the groove 2 extend to meet at one point and meet the center of the arc surface 22 Coincident, the radius R of the arc surface 22 2 and body 1 outer edge radius R 1 Equal, there are two V-shaped grooves 4 between two adjacent grooves 2, a protrusion 3 is formed between adjacent V-shaped grooves 4, the shape of the protrusion 3 matches the shape of the groove 2, and the groove 2 The shape of the protruding part between the V-shaped gr...

specific Embodiment approach 3

[0017] Embodiment 3: This embodiment differs from Embodiment 1 in that the angle a between the two planes of the groove 2 is 40°. Other structures and connections are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com