Intelligent waste wood formwork recycling system and method

A wood formwork and waste technology, which is applied in the intelligent waste wood formwork recycling system and the field of intelligent waste wood formwork recycling and reuse, can solve the problems of site occupation, environmental pollution, and poor disposal, so as to avoid blocking overlapping, The density distribution is uniform and the effect of improving the utilization rate of wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In order to facilitate the understanding and implementation of the present invention by those of ordinary skill in the art, the present invention will be further described in detail below with reference to the accompanying drawings and implementation examples. It should be understood that the implementation examples described herein are only used to illustrate and explain the present invention, but not to limit it. this invention.

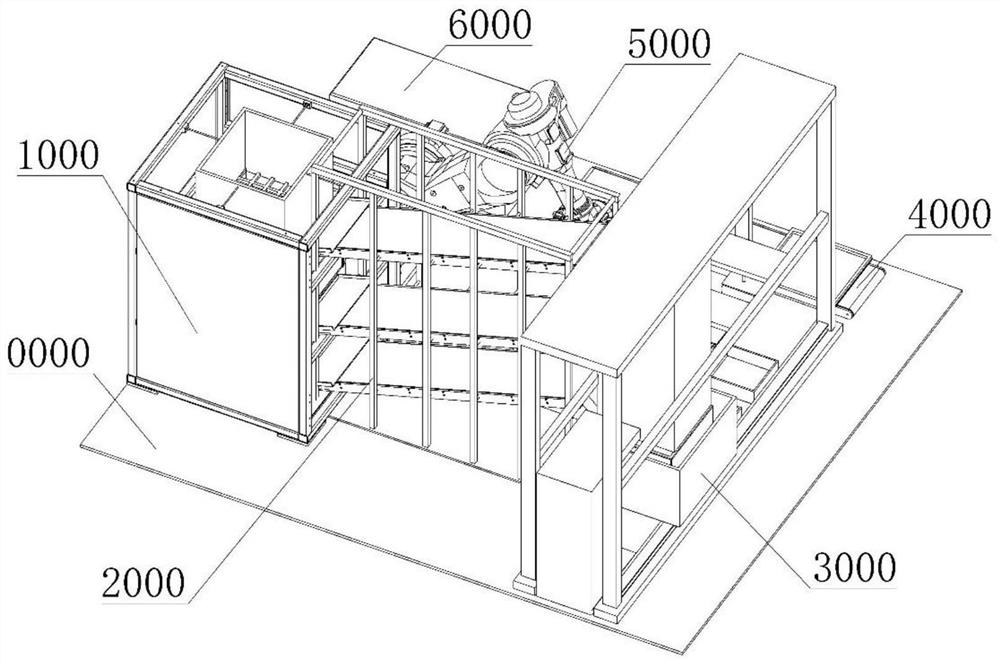

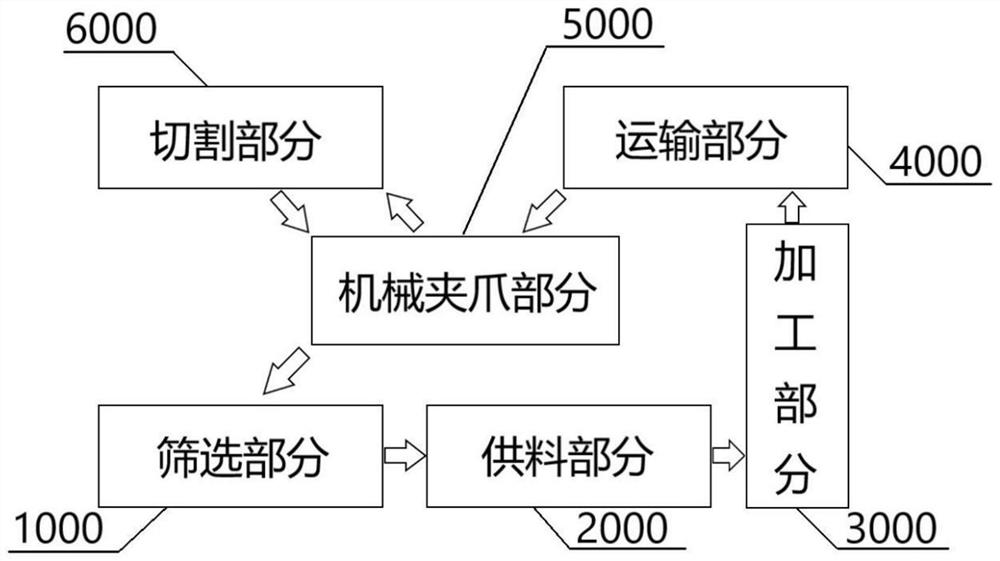

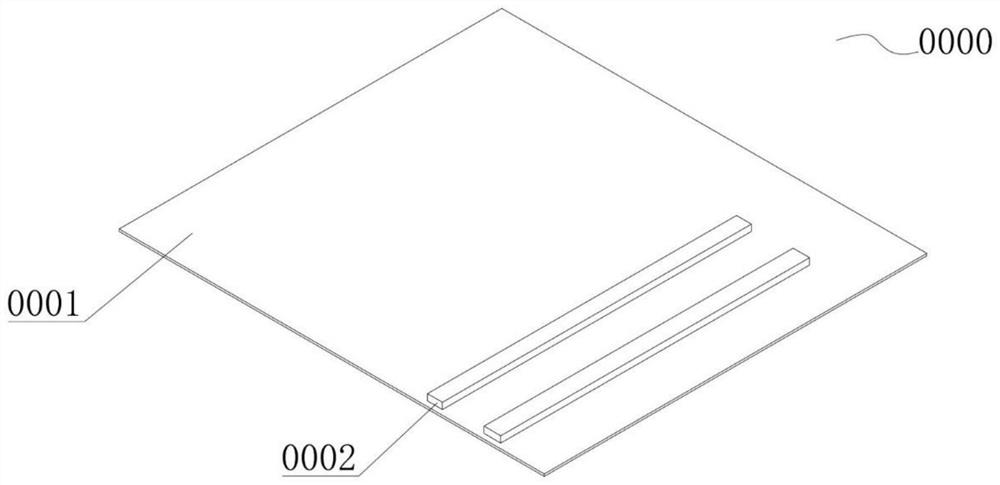

[0088] An intelligent waste wood formwork recycling system, consisting of figure 1 , figure 2As shown, it includes a platform part 0000 at the bottom and a screening part 1000 installed above the platform part 0000, a feeding part 2000, a processing part 3000, a transport part 4000, a mechanical gripper part 5000, and a cutting part 6000; the most critical of which is the screening part The part 1000, the feeding part 2000 and the processing part 3000; the screening part 1000 screens the logs of different sizes and complexities into three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com