Infinite extension hollow stand column production process

A production process and column technology, which is applied in the production process field of infinitely extending hollow columns, can solve the problems of easy dislocation of the connecting position, loose connecting parts, and increase the probability of maintenance, and achieve the effect of strengthening the connection and ensuring the smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

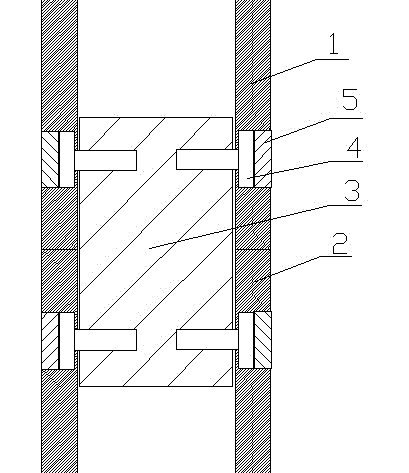

[0018] A production process for infinitely extending hollow columns, comprising:

[0019] Fill the 1 / 3-1 / 2 part of the column 3 in the upper part of the hollow column 1, use the rivet 4 to connect the upper part 1 of the column with the column 3, the rivet body of the rivet 4 is embedded in the column 3, and the rivet 4 The cap of the rivet 4 is embedded in the upper part 1 of the column, and the cap of the rivet 4 forms a retention groove with the upper part 1 of the column; the outer solid block 5 made of bamboo is bonded in the retention groove, and the shape of the outer solid block 5 is consistent with that of the solid rivet. Bit slot fit.

[0020] Fill the remaining part of the column 3 into the hollow column lower part 2, so that the column lower part 2 and the end of the column upper part 1 are docked. structure. Rivet 4 is used to connect the lower part 2 of the column with the column 3, the rivet body of the rivet 4 is embedded in the column 3, the cap of the rive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com