Food material smoking method

A technology for ingredients and smoked ingredients, which is applied to cooking utensils, plug-ins, household appliances, etc., can solve the problems of the taste of ingredients, steam lingering, and long cooking time, and achieve the effect of improving taste and aroma, avoiding shaking, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

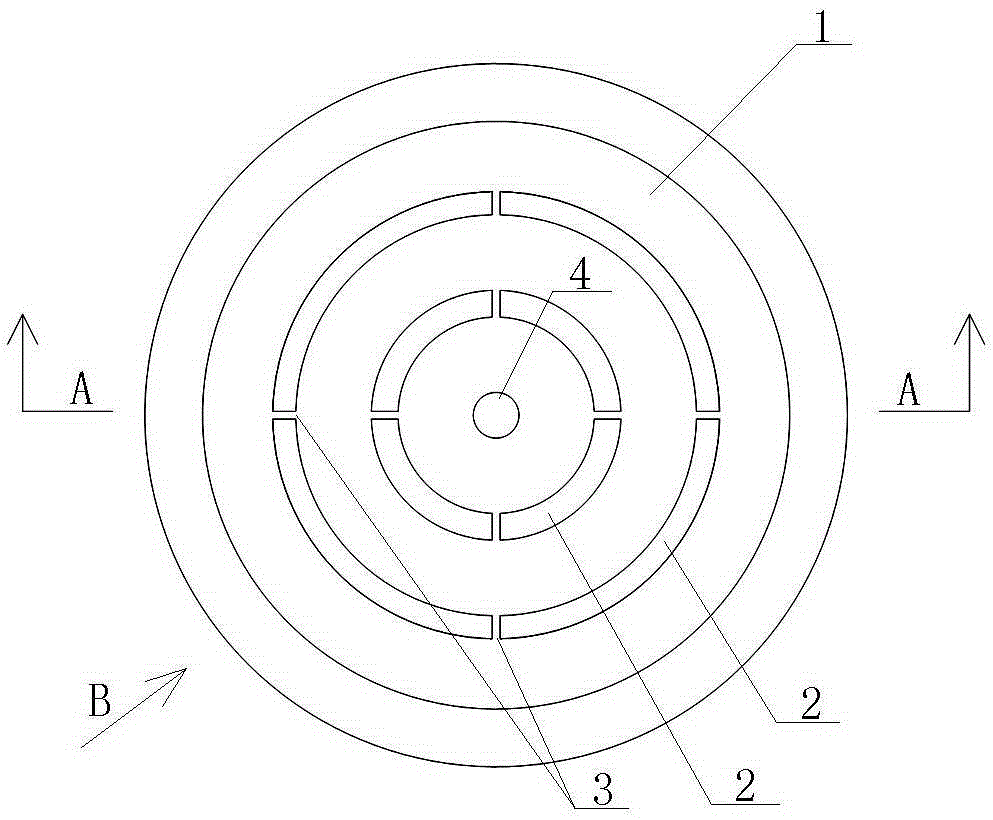

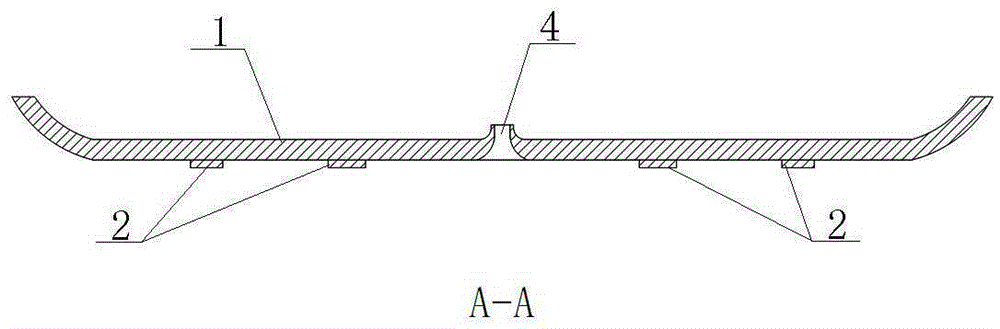

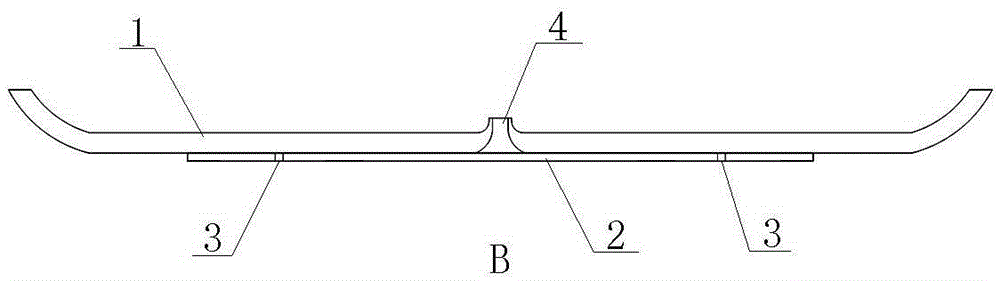

[0022] Embodiment 1: as Figure 1-6 As shown, this embodiment specifically relates to a cooking method for food materials, and the cooking method specifically includes the following steps:

[0023] (1) The realization of the steam fumigation method depends on the steamer system. First, a steamer 17 is set in the center of the dining table 5. The steamer 17 is a cylindrical cavity with a platform 9 for placing the tray 7. And there is an openable transparent cover 6 above it. The cover 6 adopts a lifting structure, which can realize automatic lifting operation through the control of the control system; there is also a steam introduction part and a steam discharge part in the steamer 17 to form a steam circulation system, the steam introduction part includes a steam nozzle 8 located in the cavity of the steamer 17, the steam nozzle 8 is connected to the external steam boiler through the steam pipeline 10, and a secondary heating device 12 is arranged in the steam pipeline 10, so...

Embodiment 2

[0028] Embodiment 2: The cooking method of the ingredients in this embodiment is the same as steps (1)-(4) in Embodiment 1, the difference is that after the output steam reaches the set time, close the valve in the steam pipeline 10 13. Stop outputting the steam, leave the steamer 17 for 5-10 seconds, and then open the cover 6 above the steamer 17 to complete the cooking of the ingredients, and start to enjoy the smoked ingredients.

[0029] It should be noted that after the steam cooking is completed, the purpose of standing the steamer for 5-10 seconds is to: (1) fully discharge the steam left in the cavity of the steamer during the steam cooking process through the exhaust and drainage pipes to avoid After opening the cover, a large amount of steam overflows and disperses, which affects the dining experience of diners; (2) During the period of standing, the aroma of the smoked materials (Chinese herbs and spices) can further penetrate into the ingredients through the residua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com