Hole position accuracy detection tool for automobile reducer shell

A technology of hole position and speed reducer, applied in instruments, measuring devices, mechanical devices, etc., can solve the problems of time-consuming detection, low detection efficiency, complicated operation, etc., and achieve the effect of fast detection, simple operation and improved detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

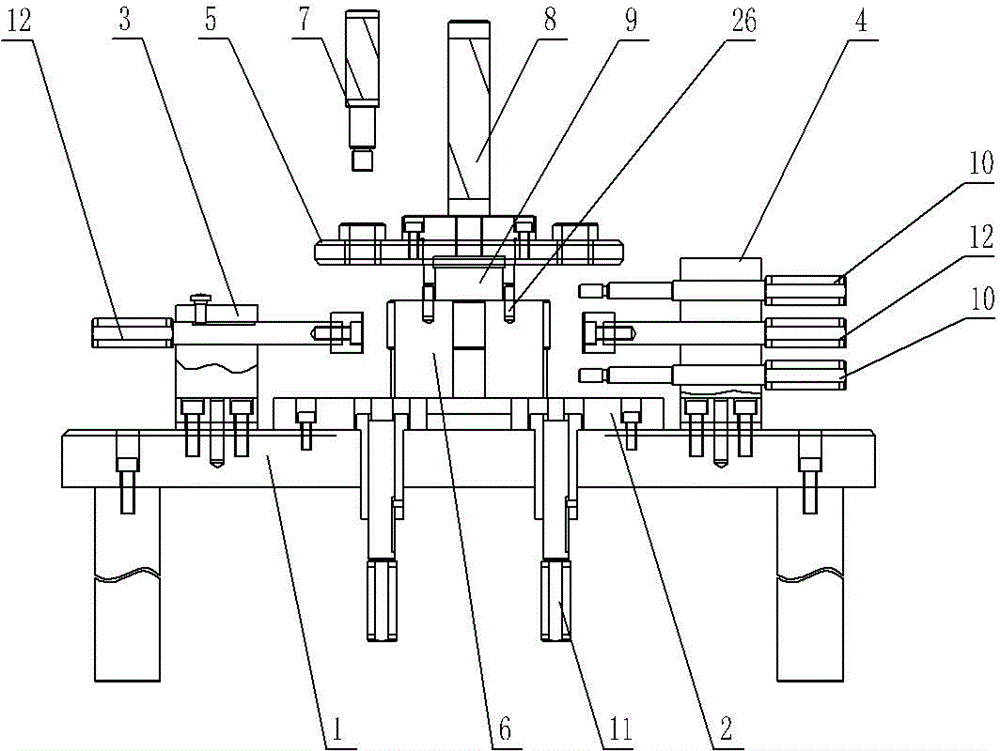

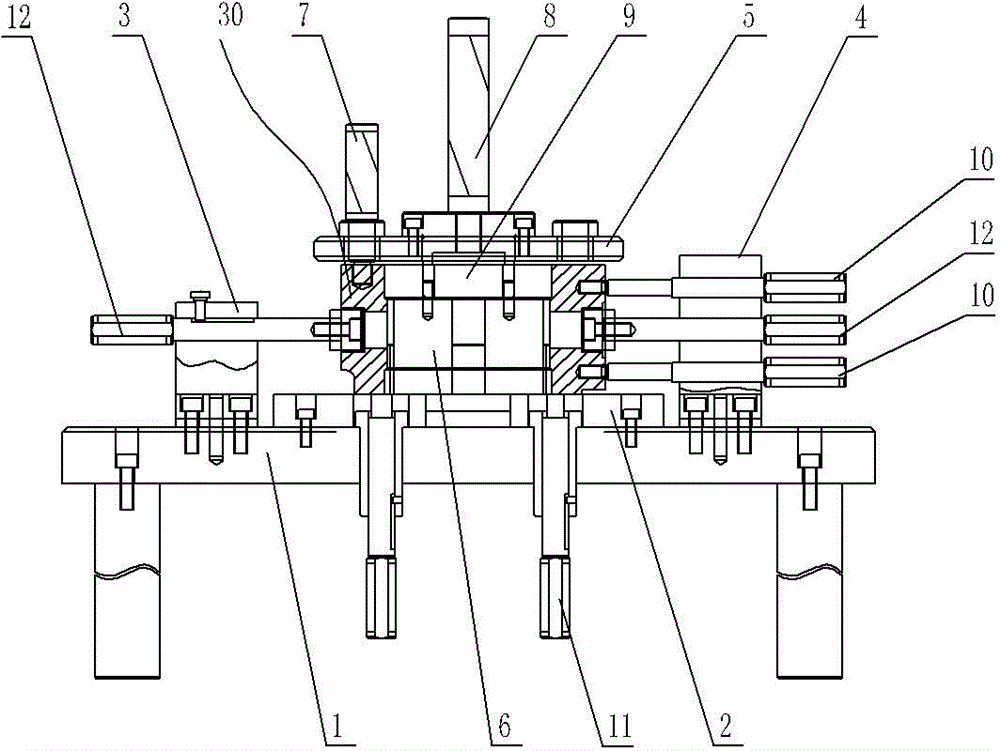

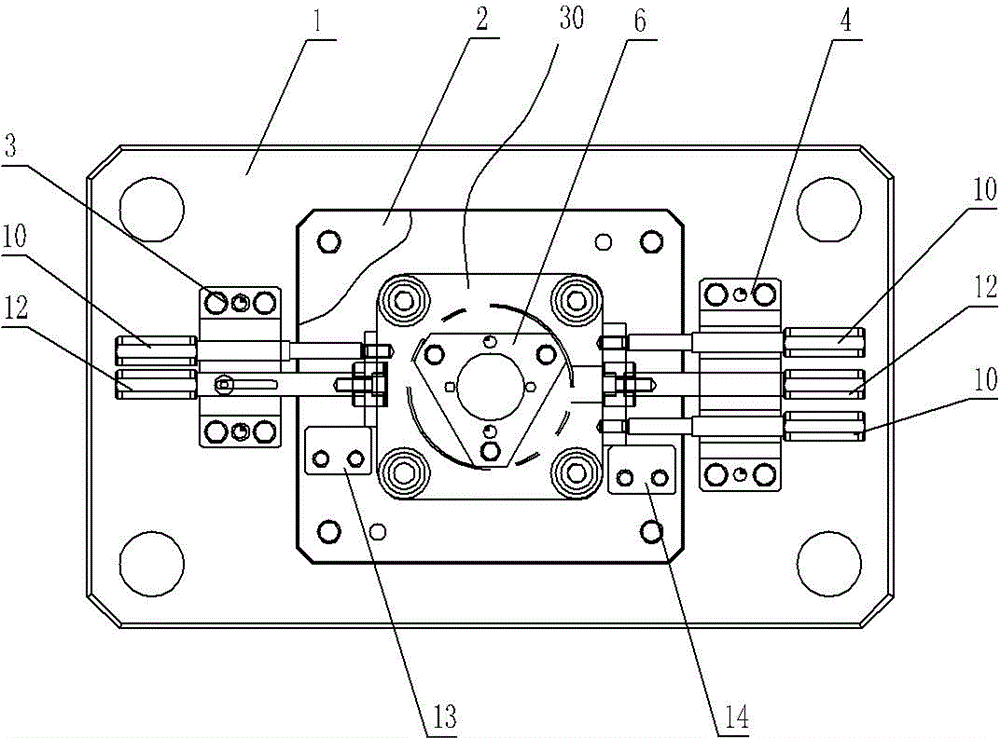

[0015] Such as Figure 1 to Figure 5 As shown, a hole position gauge for an automobile reducer housing 30 includes a base plate 1, and is characterized in that: the base plate 1 is provided with a reference seat 2, a limit block 13, and a limit block 2 14, A central hole positioning block 6 is provided on the reference base 2, and a cover plate 5 is arranged above the central hole positioning block 6, which is located on the left and right sides of the reference base 2, and a left detection seat is provided on the base plate 1. 3. The right detection seat 4 corresponds to the mounting hole and positioning hole on the left end face of the automobile reducer housing 30. The left detection seat 3 is provided with a touch gauge 12 and a thread gauge 10 corresponding to the automobile reducer housing 30. The mounting hole and positioning hole on the right end face, the right detection seat 4 is provided with a touch gauge 12 and a thread gauge 10, corresponding to the mounting hole...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap