Twisted-type hoister steel wire rope interlayer friction detection device and method

A friction detection and steel wire rope technology, which is applied in the field of interlayer friction detection devices for winding hoist wire ropes, can solve problems such as inability to detect friction and wear between ropes, and achieve wide practicability, easy operation, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

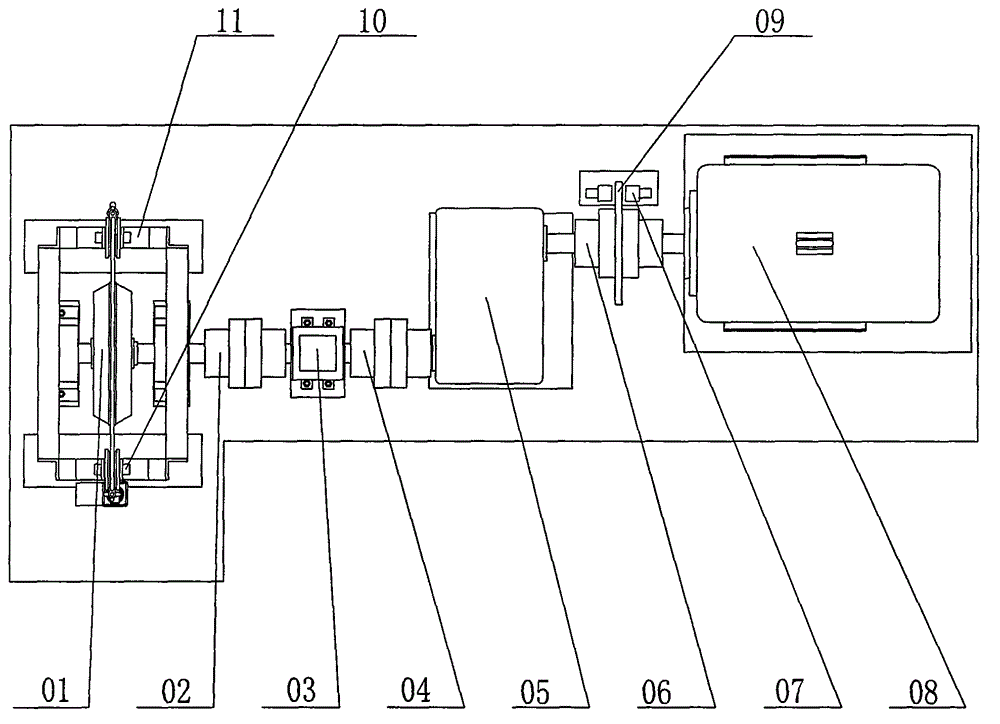

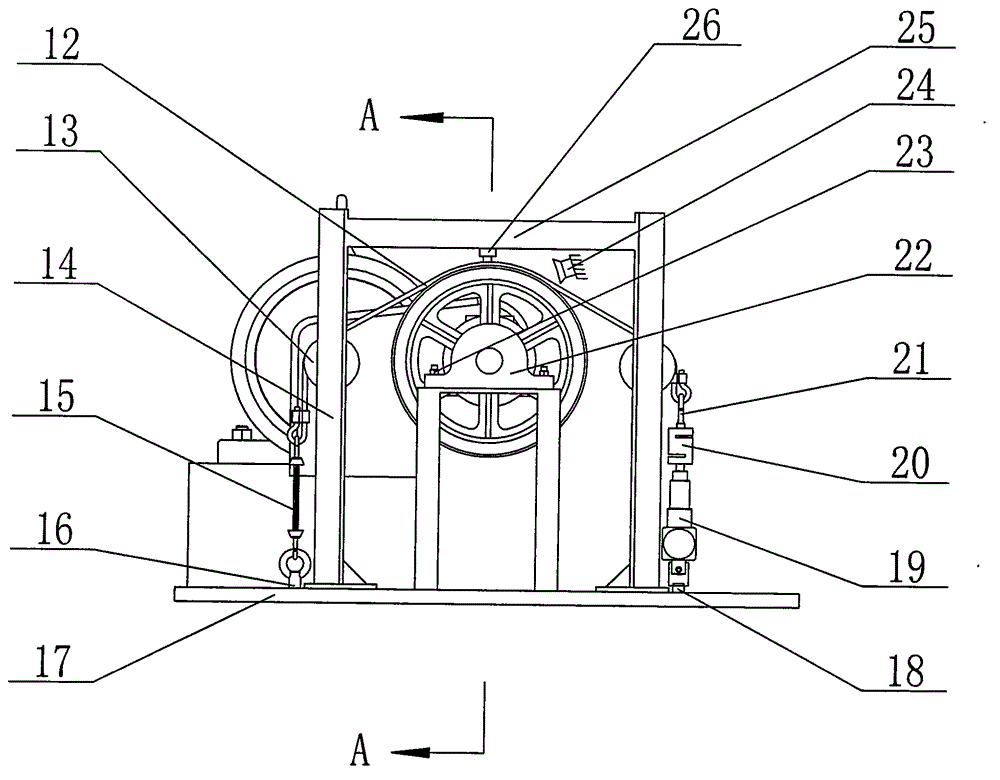

[0038] Such as Figure 1-6 As shown, a winding hoist wire rope interlayer friction detection device includes a bracket, a loading wire rope positioning system arranged on the bracket, a jointless wire rope positioning system, a braking system, a dynamic loading system, and a state monitoring system;

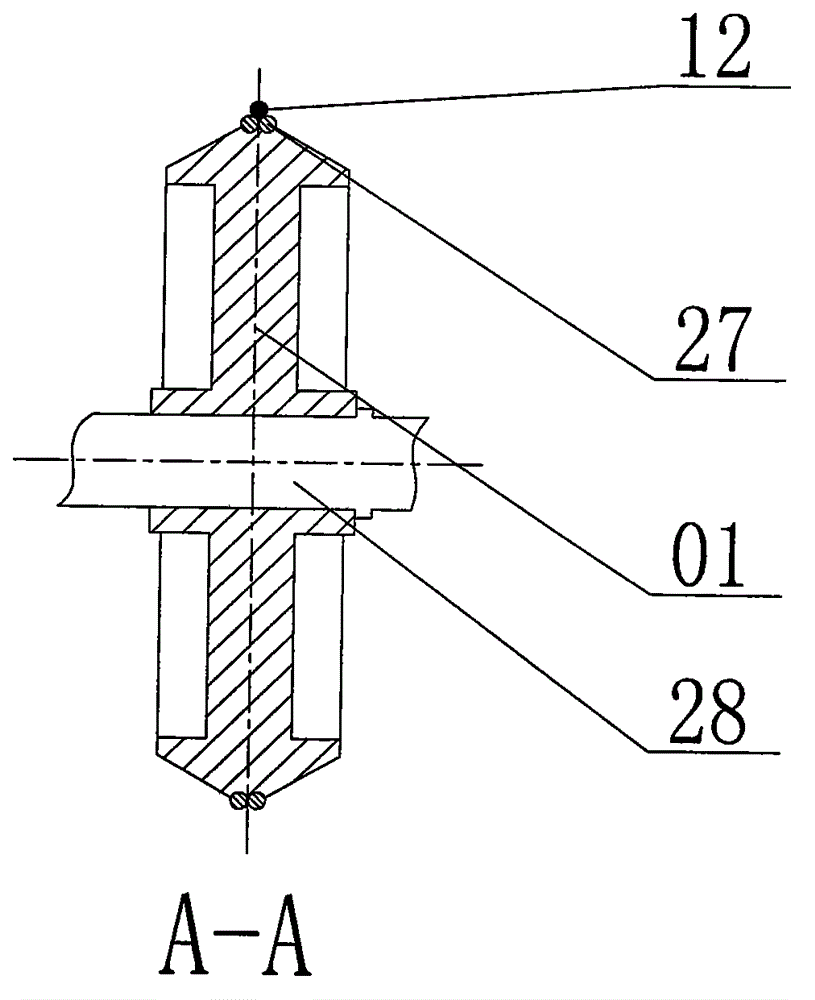

[0039] The support includes a base 17 and four columns 14 fixed on the base 17. The four columns 14 form a rectangle, and a crossbeam 25 is arranged on the top between the two vertical columns perpendicular to the axial direction of the drive shaft 28, parallel to the drive shaft. A fixed pulley support beam 11 is arranged in the middle between the two transverse columns in the axis direction of the shaft 28 .

[0040] The loading wire rope positioning system includes a fixed pulley support on the fixed pulley support beam 11, two fixed pulleys 13 symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com