Multi-filament spiral contact detection device and detection method inside steel wire rope

A steel wire rope and steel wire technology, which is applied in the field of wear and damage detection devices and multi-wire spiral contact fatigue inside the steel wire rope, can solve the problems of accelerating wire rope fatigue and broken wires, affecting the reliability of the steel wire rope, etc., and achieves simple operation, wide practicability, and high effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

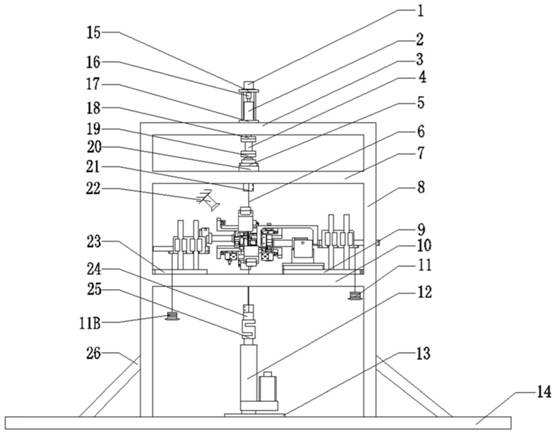

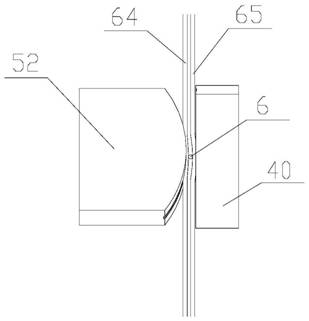

[0095] Such as Figure 1-14 As shown, the multi-wire spiral contact fatigue, wear and damage detection device inside the steel wire rope of the present invention is mainly composed of a support device, a fatigue steel wire loading assembly arranged on the support device, an intersecting angle adjustment mechanism and a positioning mechanism arranged on the support device. The intersection angle adjustment mechanism is used to adjust the intersection angle between the loading steel wire and the fatigue steel wire;

[0096] The positioning mechanism is used to drive the loading steel wire to contact the fatigue steel wire with a certain prestress;

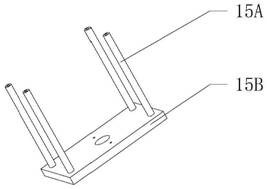

[0097] The supporting device includes four bottom beams 14 surrounded by a rectangle, four supporting columns 8 symmetrically arranged on the bottom beams 14, and four reinforcing ribs 26 are arranged at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com