Drilling machine complete equipment applied to rock-soil energy storage technology

A complete set of equipment and drilling rig technology, which is applied in the direction of earth drilling, supporting devices, rotary drilling rigs, etc., can solve the problems of detection instrument damage, environmental pollution, low construction efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below according to accompanying drawing,

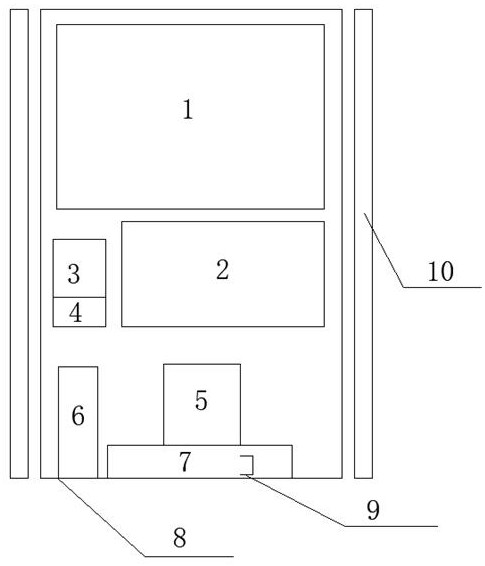

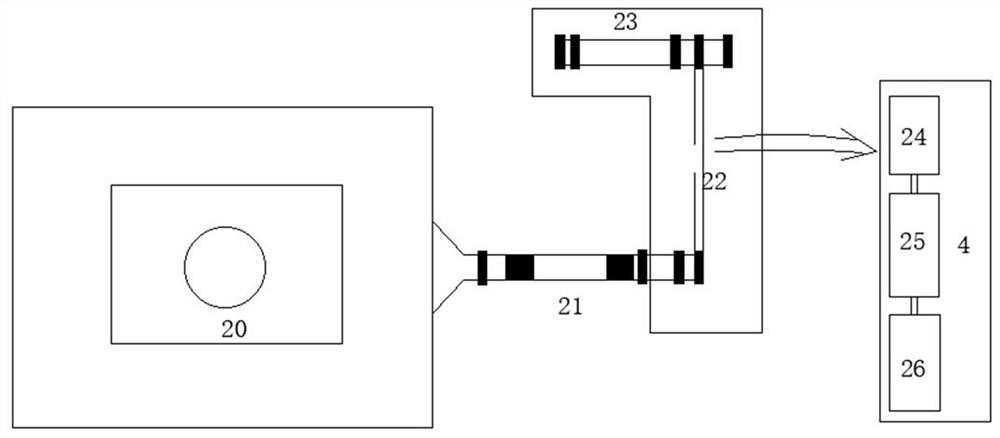

[0025] as attached figure 1 As shown, a drilling rig complete set for geotechnical energy storage technology, including mud treatment system 1, power system 2, automatic control system 3, turntable torque device 4, transmission device 5, drill pipe box 6, gantry 7, chassis 8. The mechanical arm 9 and the crawler belt 10, all the above devices are reasonably arranged on the chassis 8. The automatic control system 3, with an external remote control, can realize full automation of drilling rig movement, tripping and tripping, and real-time monitoring of drilling pressure, torque, and well deviation.

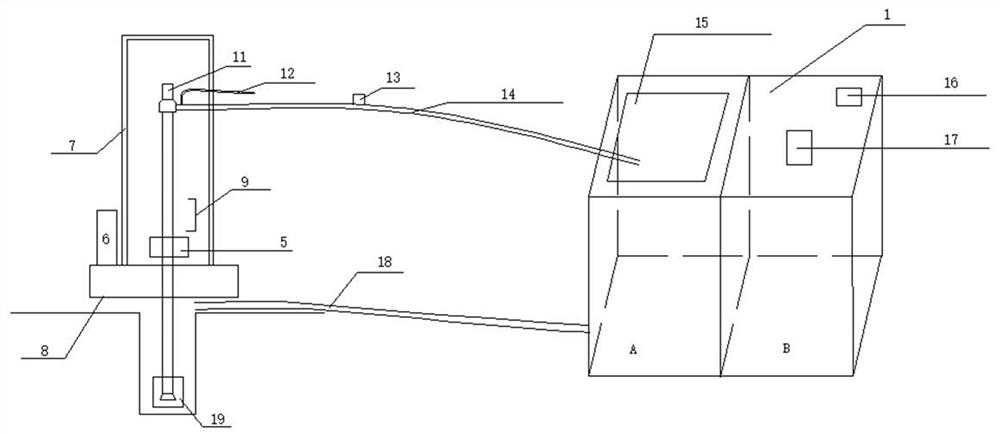

[0026] In this embodiment, combined with the figure 2 As shown, the mud treatment system 1 includes two parts, A and B. A desilter or filter press device 15 is placed on the A part, and the waste residue is discharged to the B part, and the A part and the pipeline 18 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com