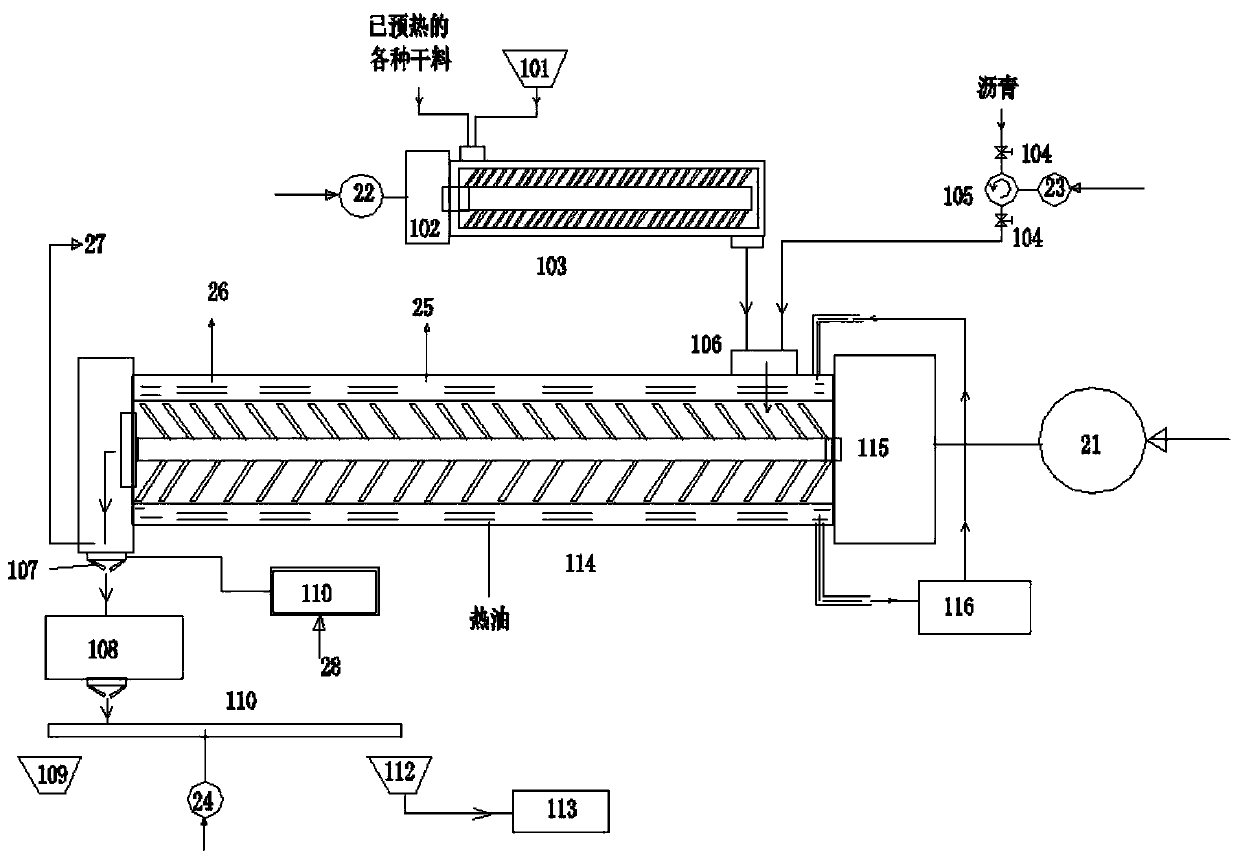

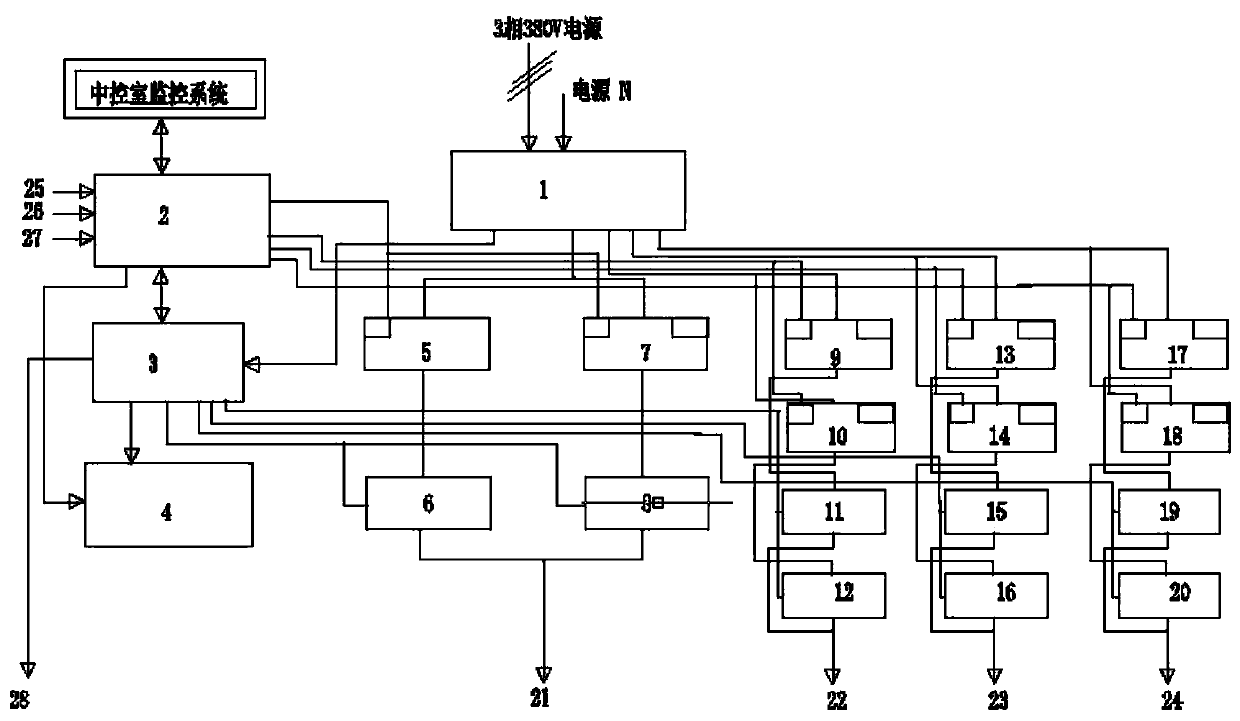

Intelligent automatic control apparatus with redundancy control of carbon kneading machine

An automatic control device, redundant control technology, applied in mixers, transportation and packaging, mixer accessories, etc., can solve the problems of human energy loss, increase production costs, poor matching of various parameters, etc., and achieve reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention includes an air circuit breaker and fuse combination device 1, redundant processing-intelligent control device 2, given and control switch combination device 3, power supply-operation-fault indication device 4, oil temperature detection thermocouple 26, oil temperature detection Pressure transmitter 25, lake material outlet temperature thermocouple 27, 1# inverter with built-in display operation panel and DP communication adapter 5, 1# AC contactor 6, 2# inverter with built-in display operation panel and DP communication adapter 7 , 2# AC contactor 8, 3# inverter with built-in display operation panel and DP communication adapter 9, 3# AC contactor 11, 4# inverter with built-in display operation panel and DP communication adapter 10, 4# AC contactor 12. 5# inverter with built-in display operation panel and DP communication adapter 13, 5# AC contactor 15, 6# inverter with built-in display operation panel and DP communication adapter 14, 6# AC contacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com