Treatment method of dissolved slag containing zinc and lead

A treatment method and solution technology, applied in the direction of protection devices against harmful chemicals, can solve problems such as environmental risks and safety hazards, high leaching content, environmental quality impact, etc., and achieve the effect of reducing risks and safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

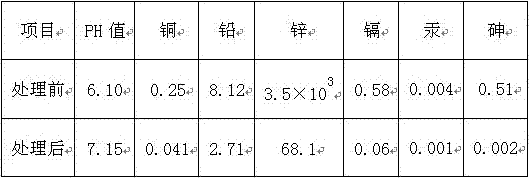

Embodiment 1

[0014] A method for processing dissolved slag containing zinc and lead, the method comprising the following steps:

[0015] A. Add the dissolved slag and barium sulfide solution to the reactor under stirring conditions, and use pH test paper to detect the pH of the material in the reactor. If the pH test paper shows that the pH of the material cannot reach pH=14, pass Adjust the addition amount of these two reactants so that the pH is not lower than pH=14, and the time is 10 minutes;

[0016] B. After the reaction in step A, continue to add the dissolved slag and barium sulfide solution to the reactor under stirring conditions, and use pH test paper to detect the pH of the material in the reactor. If it is pH test paper, it will show that the pH of the material is at 7 ≤pH<9, adjust the amount of these two reactants so that the pH is within the range of 7≤pH<9, and the time is 10 minutes;

[0017] C. After the reaction in step B, continue to add the dissolved slag and barium ...

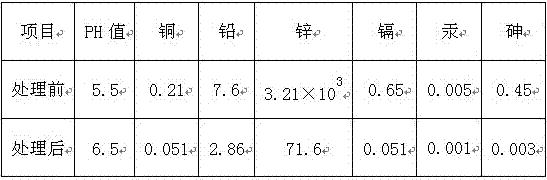

Embodiment 2

[0025] A method for processing dissolved slag containing zinc and lead, the method comprising the following steps:

[0026] A. Add the dissolved slag and sodium sulfide solution to be processed into the reactor under stirring conditions, and use pH test paper to detect the pH of the material in the reactor. If the pH test paper shows that the pH of the material cannot reach pH=14, then pass Adjust the addition amount of these two reactants so that the pH is not lower than pH=14, and the time is 15 minutes;

[0027] B. After the reaction in step A, continue to add the dissolved slag and sodium sulfide solution to the reactor under stirring conditions, and use pH test paper to detect the pH of the material in the reactor. If the pH test paper detects that the pH of the material is at 7 ≤pH<9, adjust the amount of these two reactants so that the pH is within the range of 7≤pH<9, and the time is 10 minutes;

[0028] C. After the reaction in step B, continue to add the dissolved s...

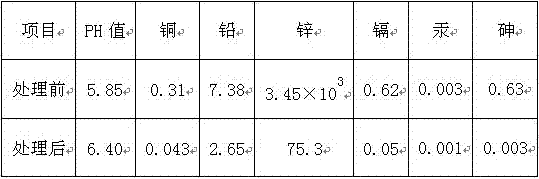

Embodiment 3

[0036] A method for processing dissolved slag containing zinc and lead, the method comprising the following steps:

[0037] A. Add the dissolved slag, barium sulfide solution and sodium sulfide solution to the reactor under stirring conditions, and use pH test paper to detect the pH of the material in the reactor. If it is pH test paper, it shows that the pH of the material cannot reach pH = 14, then by adjusting the addition amount of these three reactants, make the acidity and alkalinity not lower than pH=14, and the time is 10 minutes;

[0038] B. After the reaction in step A, continue to add the dissolved slag, barium sulfide solution and sodium sulfide solution to the reactor under stirring conditions, and use pH test paper to detect the pH of the material in the reactor. If it is pH test paper, it shows that the material If the pH is in the range of 7≤pH<9, then adjust the amount of these three reactants to make the pH in the range of 7≤pH<9, and the time is 15 minutes; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com