Inclined ladder weight-free assembling tool

A technology for assembling tooling and inclined ladders, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inclined ladder angle and step spacing error, low efficiency, affecting product quality and other problems, achieve rapid alignment, and achieve correct alignment. bit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

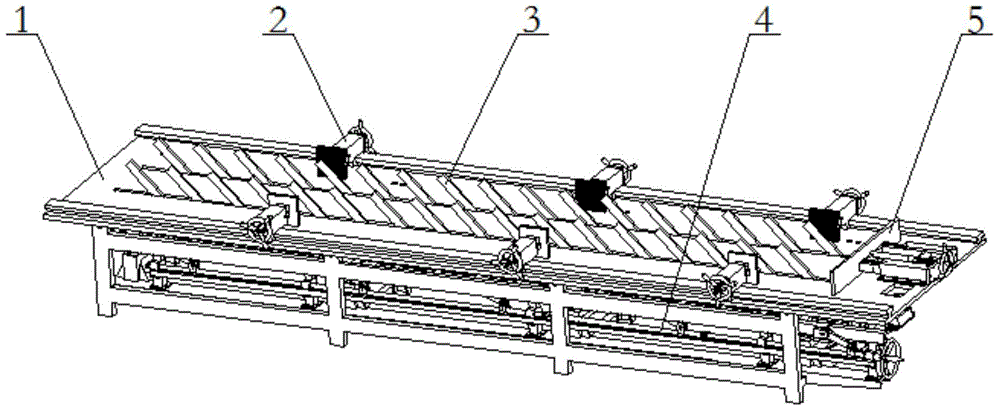

[0039] refer to figure 1 , The codeless assembly tooling of the inclined ladder of the present embodiment mainly includes: a frame 1, a first ladder beam positioning frame 2, a telescopic mechanism 3, an overturning mechanism 4, and a second ladder beam positioning frame 5.

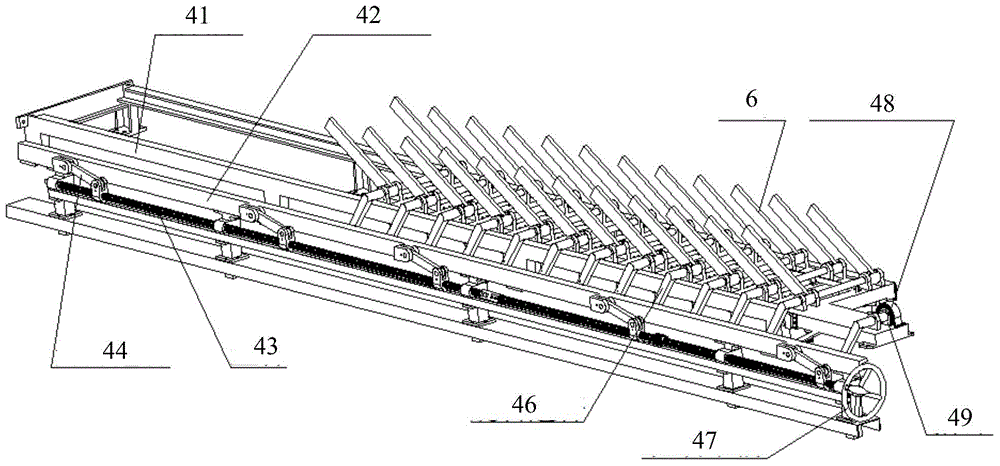

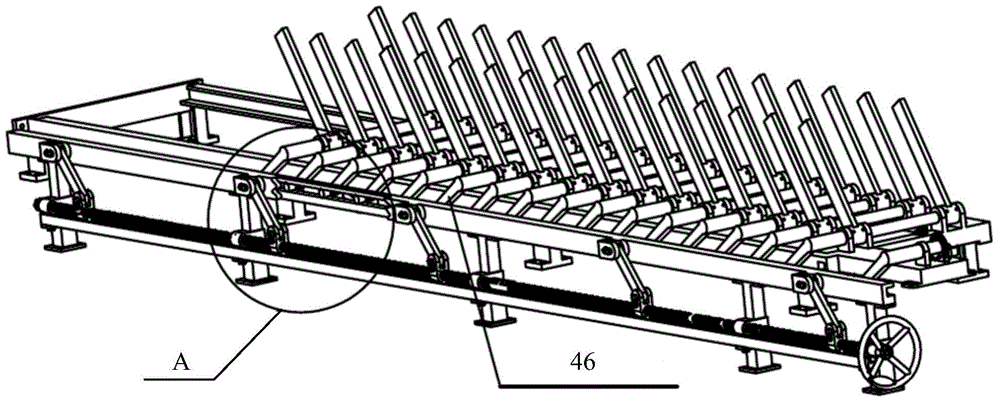

[0040] Wherein, the telescopic mechanism 3 includes a plurality of telescopic slide rails parallel to each other, and the telescopic slide rails are used to support the baffle, and the distance between adjacent telescopic slide rails is adjustable. Through the telescopic mechanism 3, the spacing of the baffles can be adjusted, and the steps of the inclined ladder are arranged on the baffles, so that the adjustment of the opening of the steps of the inclined ladder can be realized.

[0041] The tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com