Automatic quantitative cotton filling machine

A cotton machine and automatic technology, which is applied to household appliances, tools for sewing clothes, and the production of furniture covers, etc., can solve the problem that the weight of cotton cannot be effectively measured and controlled, the efficiency of cotton filling and quality are restricted, and the labor cost is increased. and other problems to achieve the effect of saving labor costs, reducing production costs and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

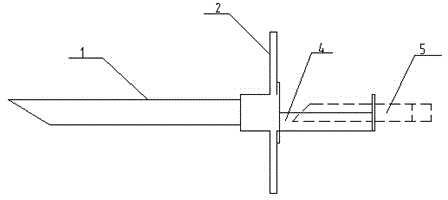

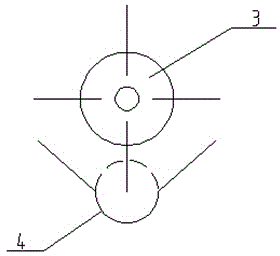

[0021] like Figures 1 to 3 The automatic quantitative cotton filling machine shown includes a cotton filling nozzle 1 fixedly connected to the flange 2, the cotton inlet end of the cotton filling nozzle 1 is provided with a disc scraper 3, and the cotton inlet end of the cotton filling nozzle 1 is provided with a The cotton storage hopper 4 is fixed in the flange step, the cotton storage hopper 4 is connected with an air outlet 5, and the disc scraper 3 is installed above the cotton storage hopper.

[0022] The cotton storage hopper 4 is a semi-cylindrical ring, and its two ends have arc-shaped transition surfaces extending to both sides. The arc curved surface can make the filling cotton fall into the cotton storage hopper 4 smoothly, and the fiber will not be caught by the metal sharp edge to affect the smoothness of the cotton output, so as to avoid the phenomenon that the cotton output is more and sometimes less.

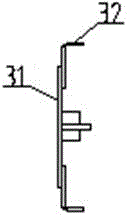

[0023] The disc scraper 3 includes a disc 31 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com