Polylactic acid/hydrogenated polybutadiene thermoplastic supramolecular elastomer and preparation method thereof

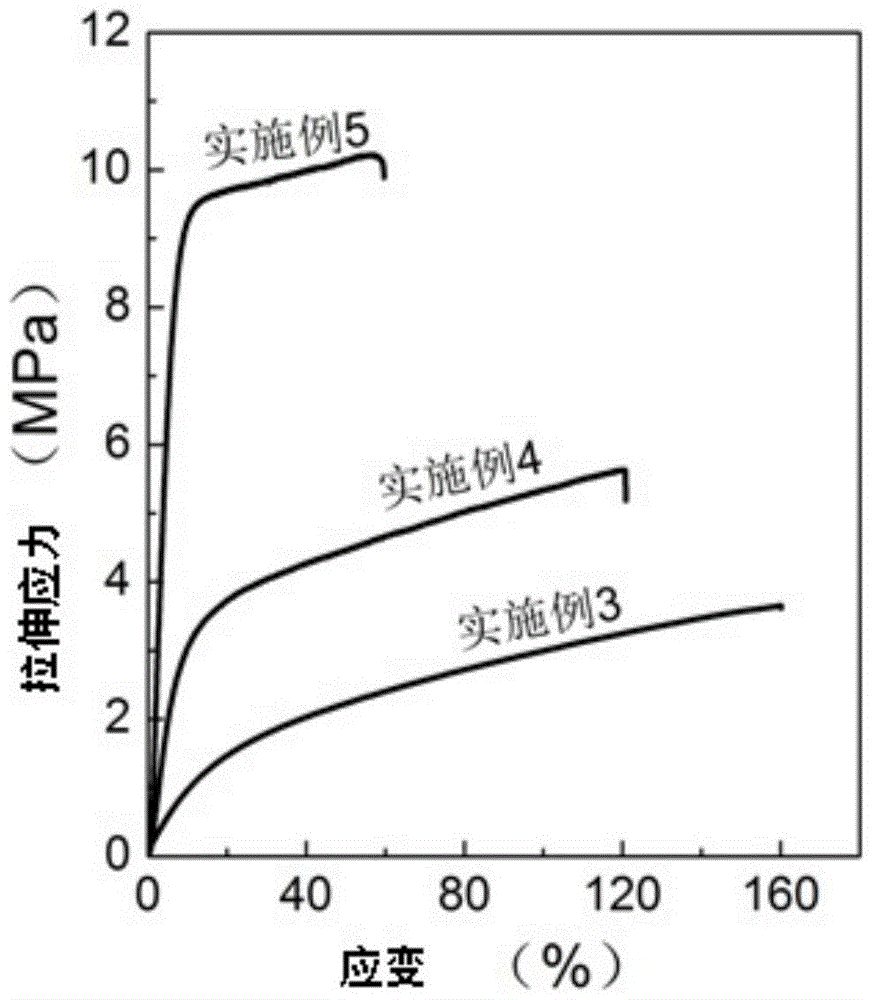

A technology for hydrogenating polybutadiene and supramolecular elastomers, applied in the field of polymer thermoplastic elastomers, can solve the problems of non-elastomeric materials, poor film-forming properties and processability of triblock copolymers, difficult preparation and the like, Achieving the effect of good mechanical performance, less pollution and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

[0024] In the following examples, the double-terminal hydroxyl-modified PEB used was purchased from Sartomer, USA. The lactide used was purchased from Praque, recrystallized in ethyl acetate to remove impurities, and dried in vacuum at 60°C to constant weight;

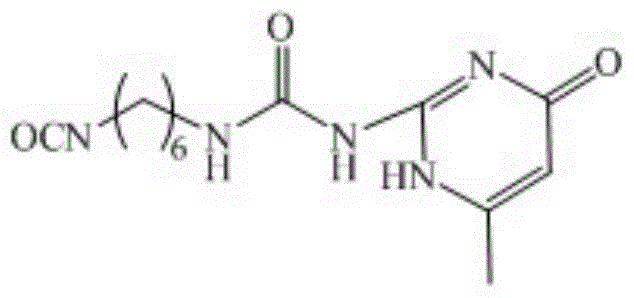

[0025] The structural formula of UPy-NCO of the present invention is:

[0026]

[0027] UPy-NCO was prepared according to the method described in the literature (Sontjens et al. Macromolecules, 2008, 41:5703-5708), the specific method is as follows: 2-amino-4-hydroxy-6-methylpyrimidine (20.0g) was added to 500ml In a three-necked flask, vacuumize at 50°C for 1 hour, fill with argon for protection, add 180.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com