Hydraulic control block with valve discs

A technology of control block and valve plate, applied in the direction of valve details, valve device, valve shell structure, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

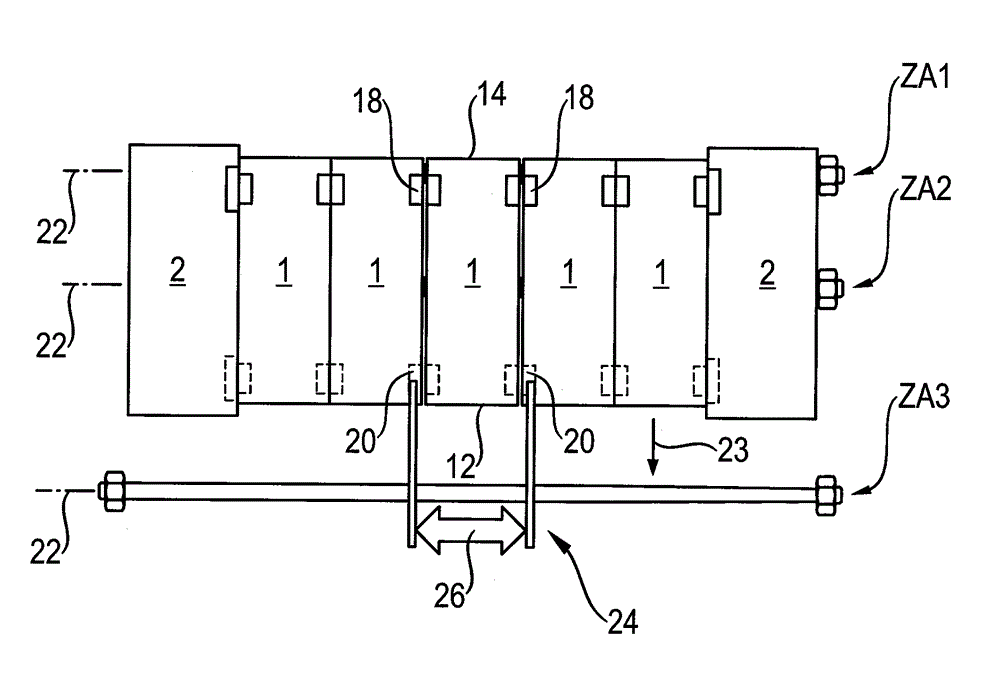

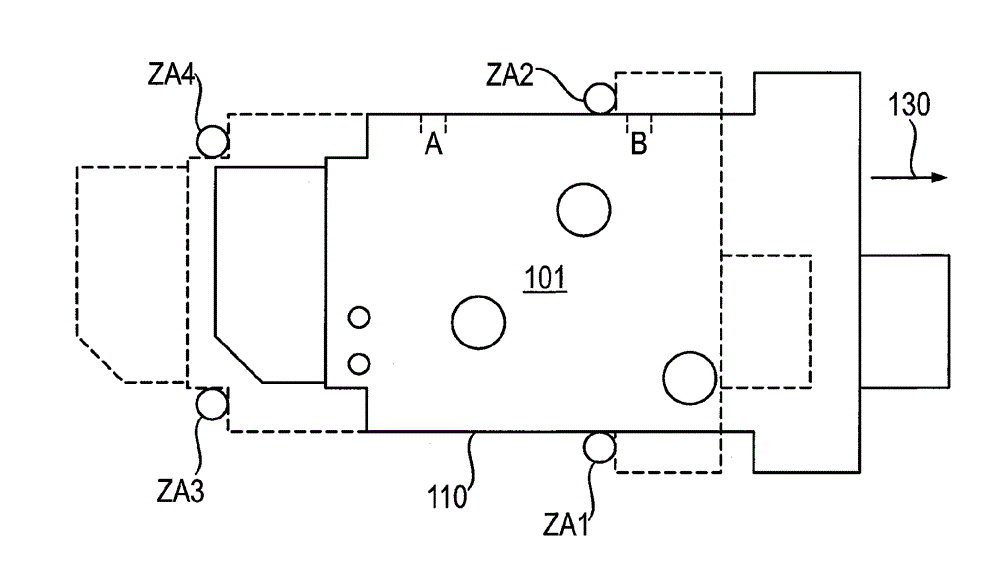

[0042] figure 1 A top view of a first embodiment of a control block according to the invention is shown. The control block has five valve plates 1 which are clamped together between a connecting plate 2 on the one hand and an end plate 4 on the other hand. Three tie rods ZA1 , ZA2 , ZA3 are used for this, each consisting of a rod-shaped body extending transversely through the valve plate 1 and the plates 2 , 4 and two nuts.

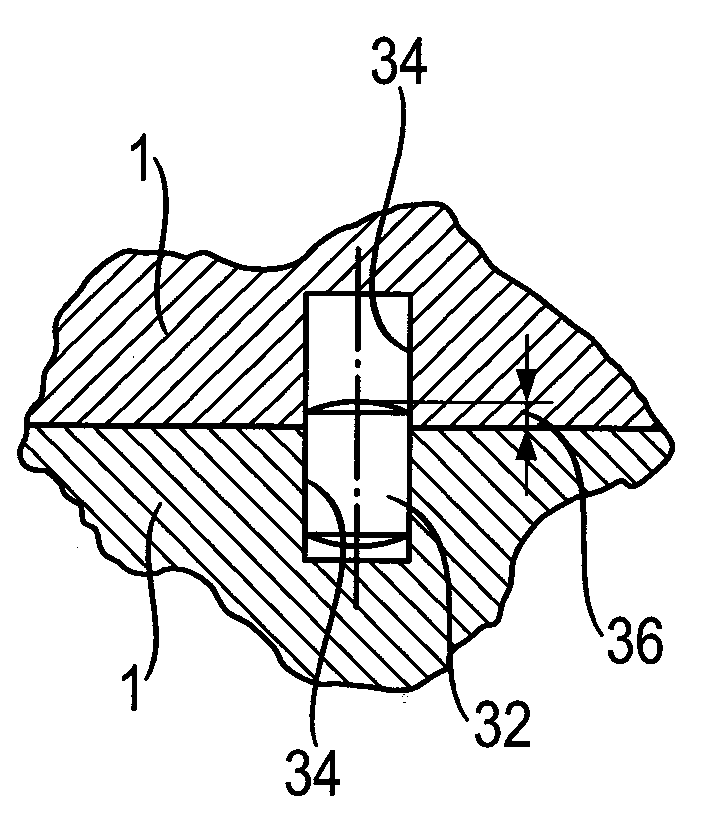

[0043] figure 2 shows the basis figure 1Side view of the middle valve section of the control block. Here, three tie rods ZA1 , ZA2 , ZA3 are shown in section. They are accommodated in corresponding recesses 6 , 8 , 9 . More precisely, in each valve section 1 in its figure 2 and on the outer side 10 of the lower part in the installation position, the lower approximately U-shaped recess 9 is drawn out, while the front U-shaped recess 8 is drawn out on the outer side 12 of the front part and on the rear part Draw out the U-shaped notch 6 of rear por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com