Closed scale-inhibiting and cooling system for wet production of acetylene from calcium carbide

An acetylene closed-type cooling system technology, applied in the direction of generator ventilation/cooling device, etc., can solve the problems of easy scaling of cooling equipment and unguaranteed heat exchange effect, so as to improve operation safety, reduce production volume, and reduce production amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

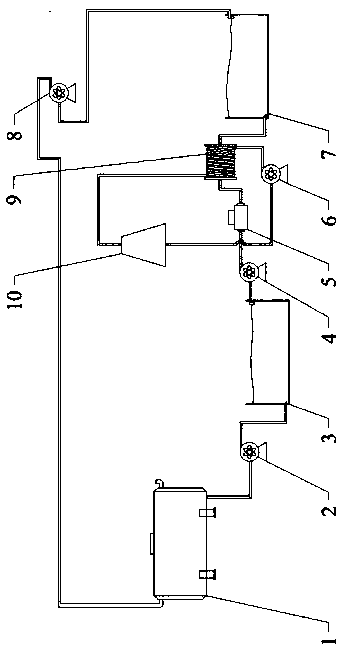

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly. like figure 1 As shown, calcium carbide blocks with a particle size of 50mm-80mm react with sufficient water in the acetylene generator (1) to generate acetylene gas and carbide slurry, and a large amount of heat will be released during the reaction process. The acetylene gas is discharged from the top of the acetylene generator (1), and the calcium carbide slurry is pumped from the bottom of the acetylene generator 1 into the concentration pool (3) by the pump A (2). During the reaction, a large amount of heat is released to make the concentration pool (3) ) in the slag slurry rises to 55°C; the calcium carbide slag slurry is stratified after standing in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com