Prediction method of thermal reactivity of coke

A technology of thermal reactivity and prediction method, which is applied in the direction of fuel oil testing, material inspection products, etc., can solve the problems of heavy test workload and long cycle, and achieve the effect of high degree of fit, few factors, and low requirements for physical conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

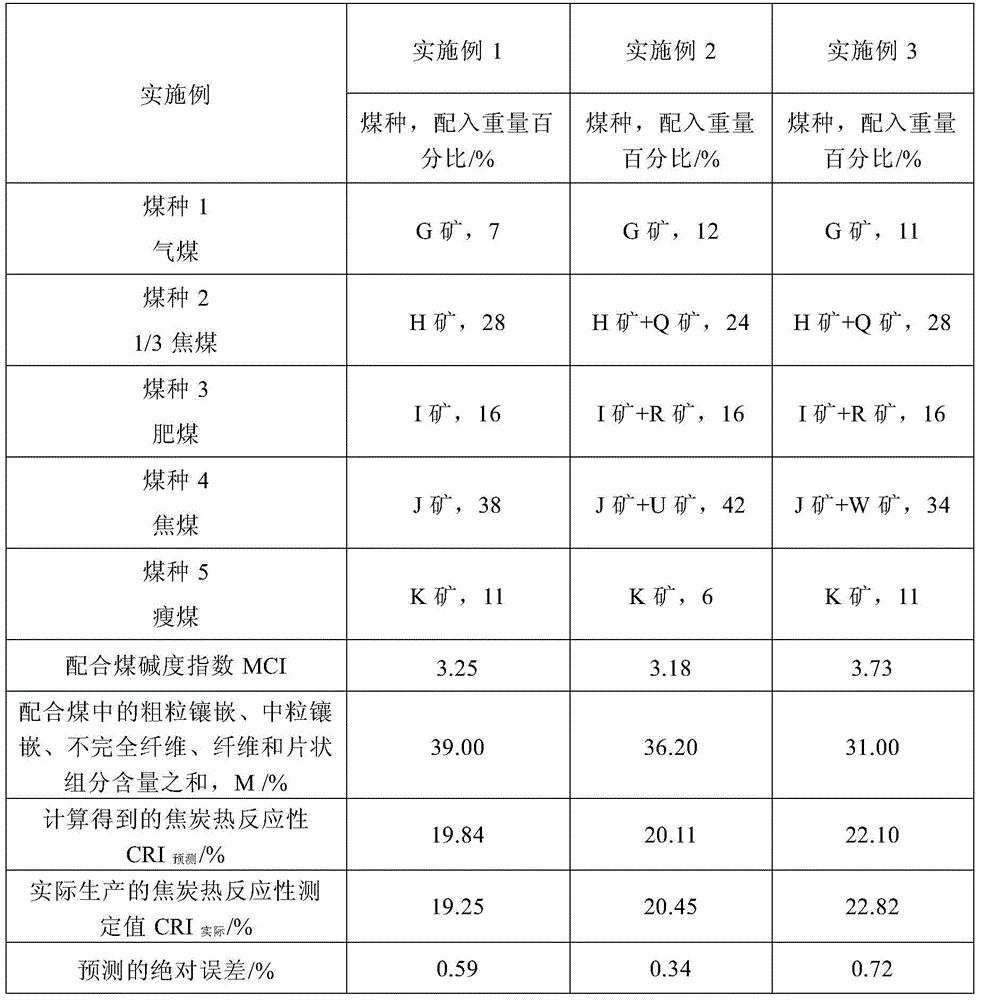

[0018] The present invention will be described in further detail below in conjunction with specific embodiments.

[0019] Method of the present invention comprises the steps:

[0020] 1) Determine the components of each single coal ash used in coking, and calculate the mixed coal alkalinity index MCI;

[0021] 2) Measure the coke-forming optical structure of each single coal used for coking, and calculate the sum M of the coarse-grain mosaic, medium-grain mosaic, incomplete fiber, fiber and sheet-like components in the blended coal;

[0022] 3) Set CRI=A+B*MCI+C*M, where CRI is coke thermal reactivity, unit is %, A, B, C are constants, by substituting three groups of coal blending coking tests or actual production data into the Calculated by the formula;

[0023] 4) Calculate the predicted value of coke thermal reactivity CRI according to the formula in step 3).

[0024] If the calculated coke thermal reactivity prediction value CRI 预测 If it cannot meet the needs of blast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com