A double rotor hammer ore crusher

A double-rotor crusher technology, which is applied in the field of mining machinery and equipment, can solve the problems of force crushing of ores of different sizes, low ore crushing efficiency, and low production efficiency, so as to increase the number of ore crushing times, enhance the ore crushing effect, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

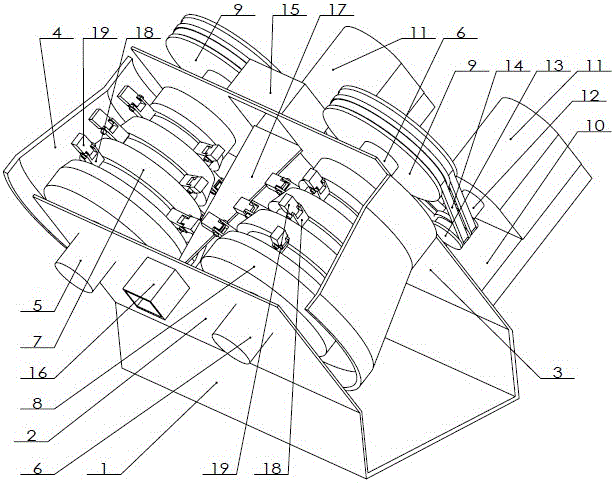

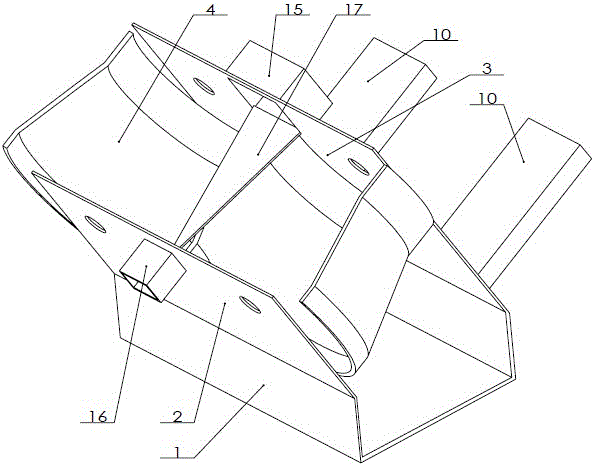

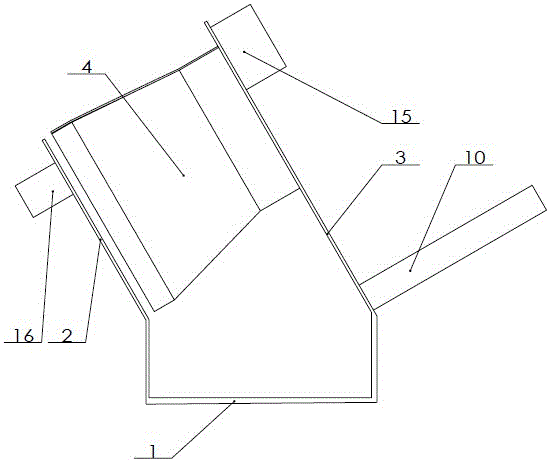

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a double-rotor hammer ore crusher includes a bottom plate 1, a front mounting plate 2 and a rear mounting plate 3, a protective cover 4, a first rotor 5 and a second rotor 6, a first blow bar mounting shaft 7 and a second Two blow bar mounting shafts 8, two large pulleys 9 and two small pulleys 13, two motor mounting plates 10 and two three-phase asynchronous motors 11, ore inlet hood 15 and ore outlet hood 16, ore shunt 17 1. Bottom blow bar 18 and end blow bar 19, characterized in that: the front mounting plate 2 and the rear mounting plate 3 are respectively installed in parallel on the front and rear ends of the bottom plate 1, and maintain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com