Impact flat hammer crusher

A technology of impact crusher and crusher, which is applied in the direction of grain processing, etc. It can solve the problems of troublesome material equalization, random flying of materials, and difficulty in cleaning work, so as to increase the number of crushing times, rationally set up the structure, and reduce random flying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

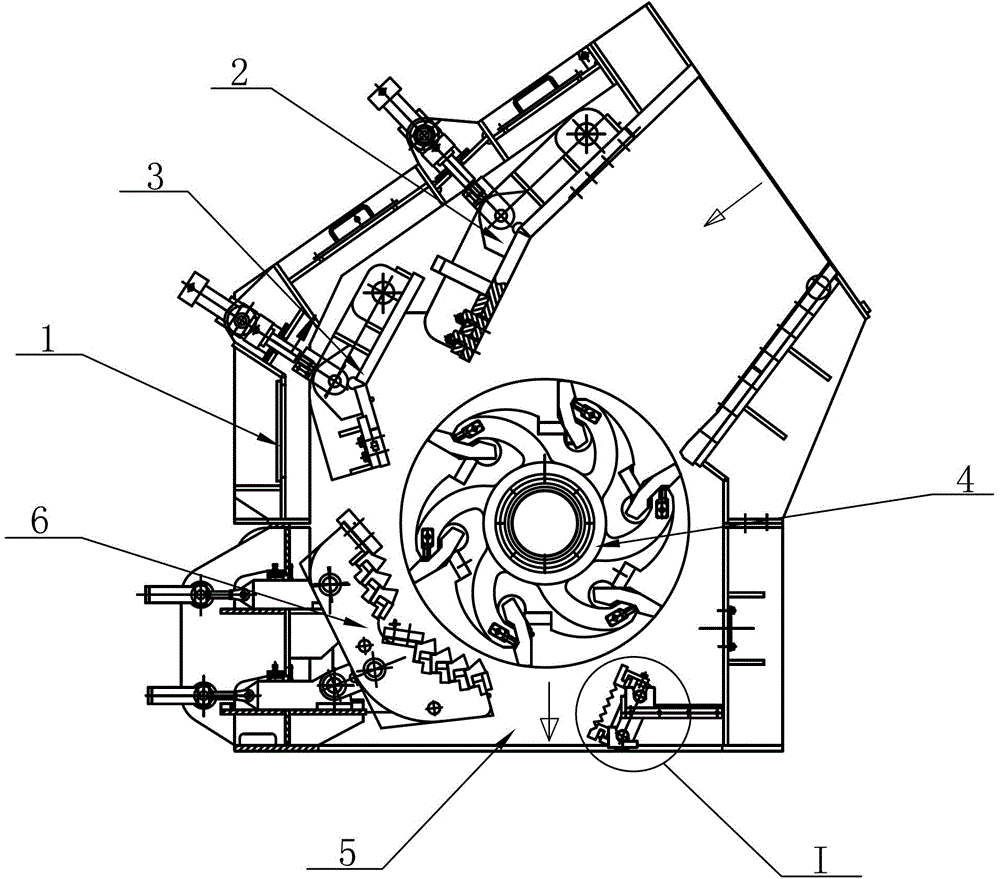

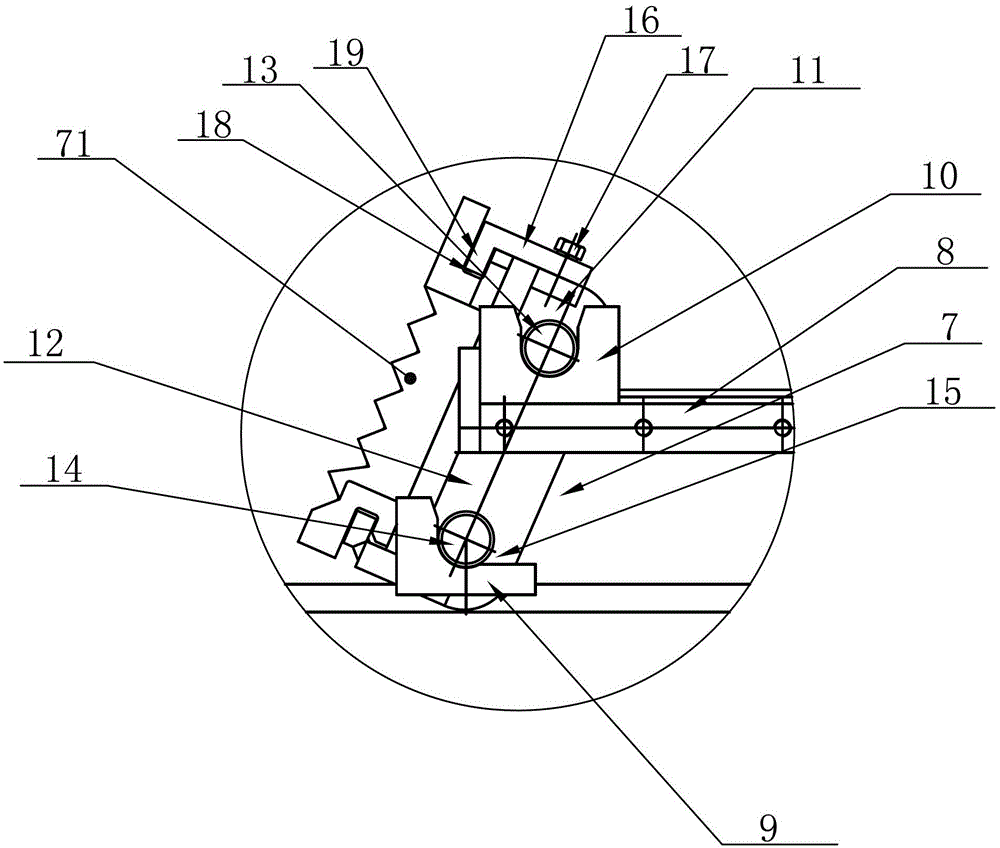

[0014] see figure 1 with figure 2 , A counterattack blow bar crusher disclosed by the present invention comprises a machine body 1, a first counterattack device 2, a second counterattack device 3 and a rotor 4 are arranged inside the machine body 1, and an outlet is arranged on the body 1 below the rotor 4. A material outlet 5, a third counterattack device 6 is provided on one side of the discharge outlet 5, and a fine material device 7 is provided at the outlet 5 on the other side of the third counterattack device 6, and the fine material device 7 includes The fine material baffle 71 is arranged towards the working surface of the third counterattack device 6 . The working surface of the third counterattack device 6 is a corrugated surface and is provided with a plurality of lugs, which can evenly distribute the material to the action area of the blow bar on the rotor 4 .

[0015] In order to make the structure of the present invention more reasonable and the work more re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com