Cable fixing clip for turning corner

A technology of cable clamps and fixing clamps, which is applied in the direction of pipe brackets, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of inconvenient installation and operation, low efficiency of wiring construction, and large space occupied by clamps, etc., and achieve simple structure , Strong practicability, prolonging the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

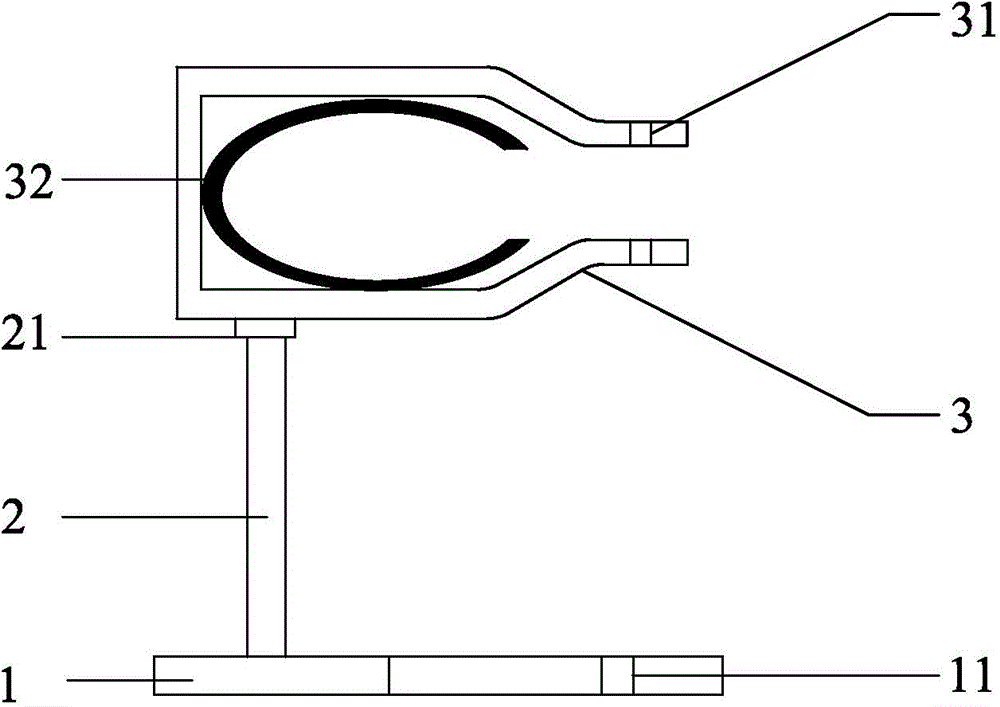

[0020] like figure 1 As shown, a corner cable fixing clip includes a support base 1 and a cable clamping portion 3 connected by a rotating shaft support frame 2, the support base 1 is an L-shaped bidirectional fixed base for fixing at a corner, the The two branch ends of the support base 1 are provided with fixing holes 11;

[0021] The rotating shaft support frame 2 is a telescopic support frame, and the rotating shaft support frame 2 can rotate in the horizontal direction around the fixed end of the support base 1;

[0022] The cable clamping portion 3 includes a cable accommodating cavity formed by a rectangular frame with one end open and a locking end fixed on the end of the cable accommodating cavity, and an annular shock-absorbing friction pad 32 is arranged inside the accommodating cavity. The locking end is provided with a locking hole 31 .

[0023] A conversion table 21 is provided at the fixed end of the rotating shaft support frame 2 and the cable clamping portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com