Heat energy measurement method of heat transfer oil

A measurement method and heat transfer oil technology, which can be used in measuring heat, calorimeters, measuring devices, etc., can solve the problem of inaccurate Q value, and achieve the effect of accurate calculation results and scientific calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

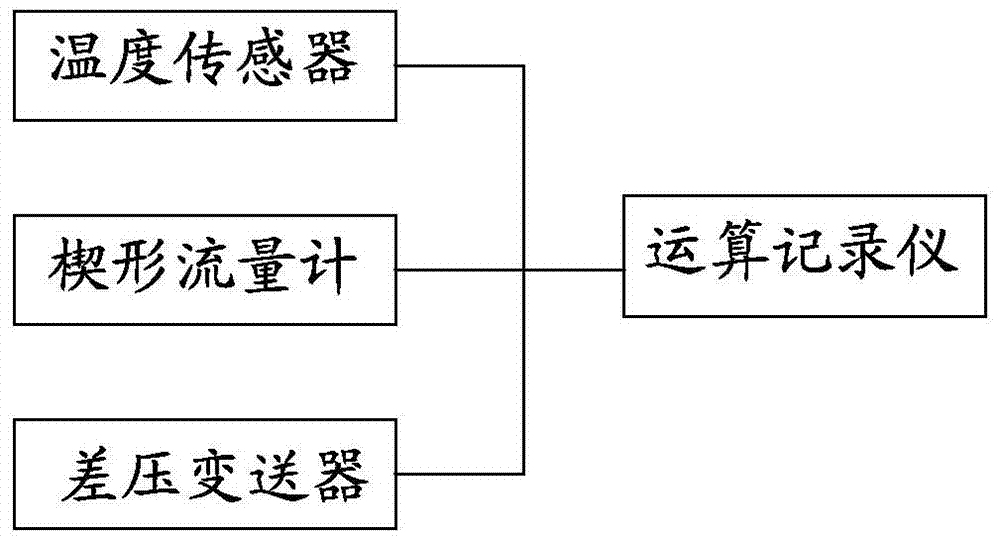

[0030] Such as figure 2 As shown, the heat transfer oil thermal energy metering system used in the present invention includes a temperature sensor, a wedge flowmeter, a differential pressure transmitter and an operation recorder, and an on-site instrument box can also be set up to integrate the temperature sensor, wedge flowmeter, and differential pressure transmitter. The instruments of the transmitter and the operation recorder are centrally arranged in the field instrument box, which is easy to observe and operate in a unified manner.

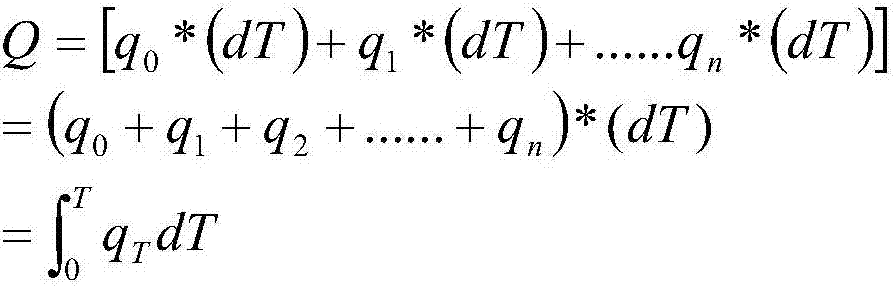

[0031] Based on the above-mentioned system, the heat transfer oil thermal energy measurement method of the present invention includes:

[0032] Step 10, using a temperature sensor to collect the temperature t of the heat transfer oil in real time;

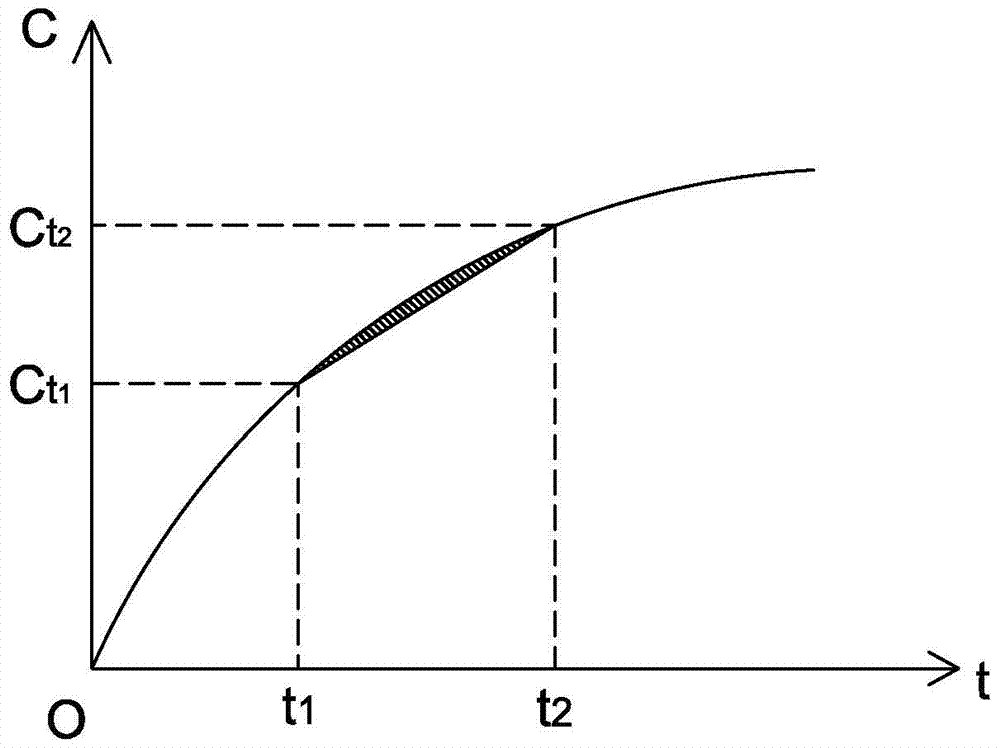

[0033] Step 20, use the operation recorder to query in real time the specific heat capacity C(t) and density ρ(t) of the heat transfer oil corresponding to the collected temperature t;

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com