Large-diameter heavy pipe lifting device

A hoisting device and heavy tube technology, which is applied in the direction of transportation and packaging, load hanging components, rod connection, etc., can solve the problems of heavy tubes that are easy to wear, energy waste, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

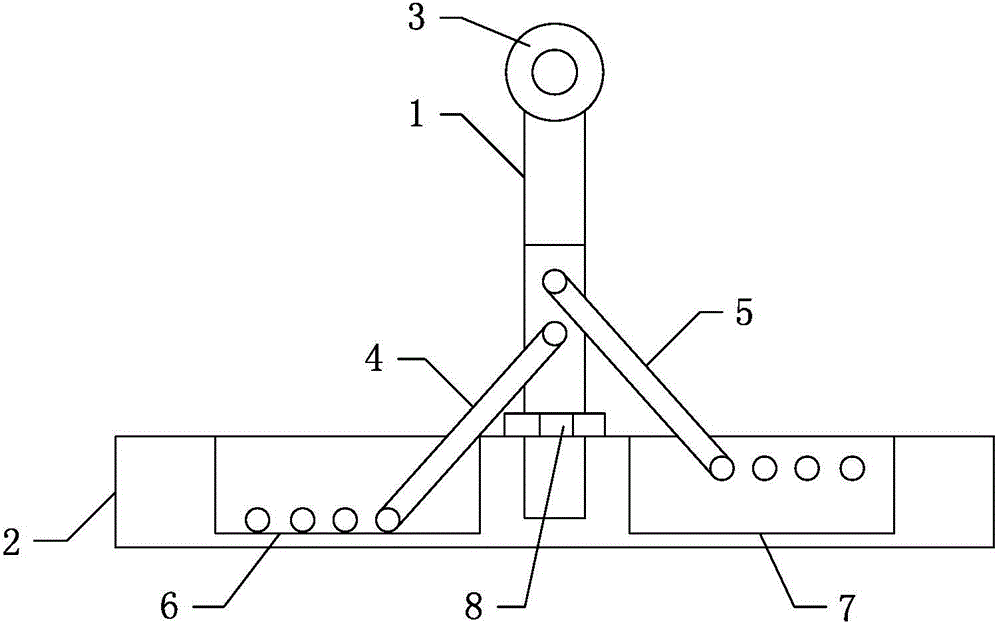

[0023] Such as figure 1 The large-diameter heavy pipe hoisting device shown includes a hoisting base 1 and a hoisting rod 2;

[0024] The hoisting base 1 is disc-shaped;

[0025] The lower part of the lifting rod 2 is a threaded rod, and is vertically assembled on the center of the upper end surface of the lifting base 1 through threads;

[0026] The upper end of the lifting rod 2 is provided with a hanging ring 3 for hoisting;

[0027] With reference to the central axis of the lifting rod 2, the symmetrical outer wall of the lifting rod 2 is hinged with a left oblique rod 4 and a right oblique rod 5;

[0028] The hinge position of the left oblique bar 4 and the hinge position of the right oblique bar 5 are located on the same vertical straight line, and the hinge position of the right oblique bar 5 is located below the hinge position of the left oblique bar 4;

[0029] The left groove 6 for the insertion of the left diagonal rod 4 and the right groove 7 for the insertion o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap