A vertical powder cooler

A cooler and powder technology, applied in the direction of direct contact heat exchanger, heat exchanger type, treatment of discharged materials, etc., can solve the problems of poor cooling effect, high energy consumption, and high probability of failure, and achieve installation and maintenance. The effect of convenience, lower production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

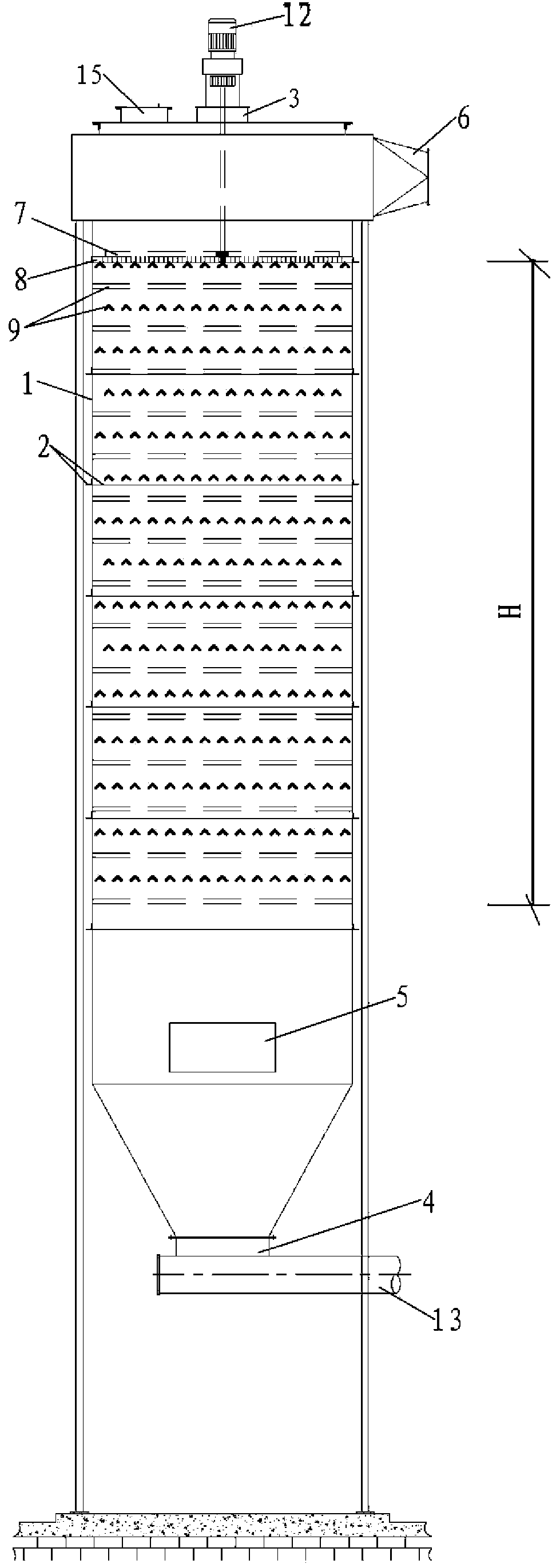

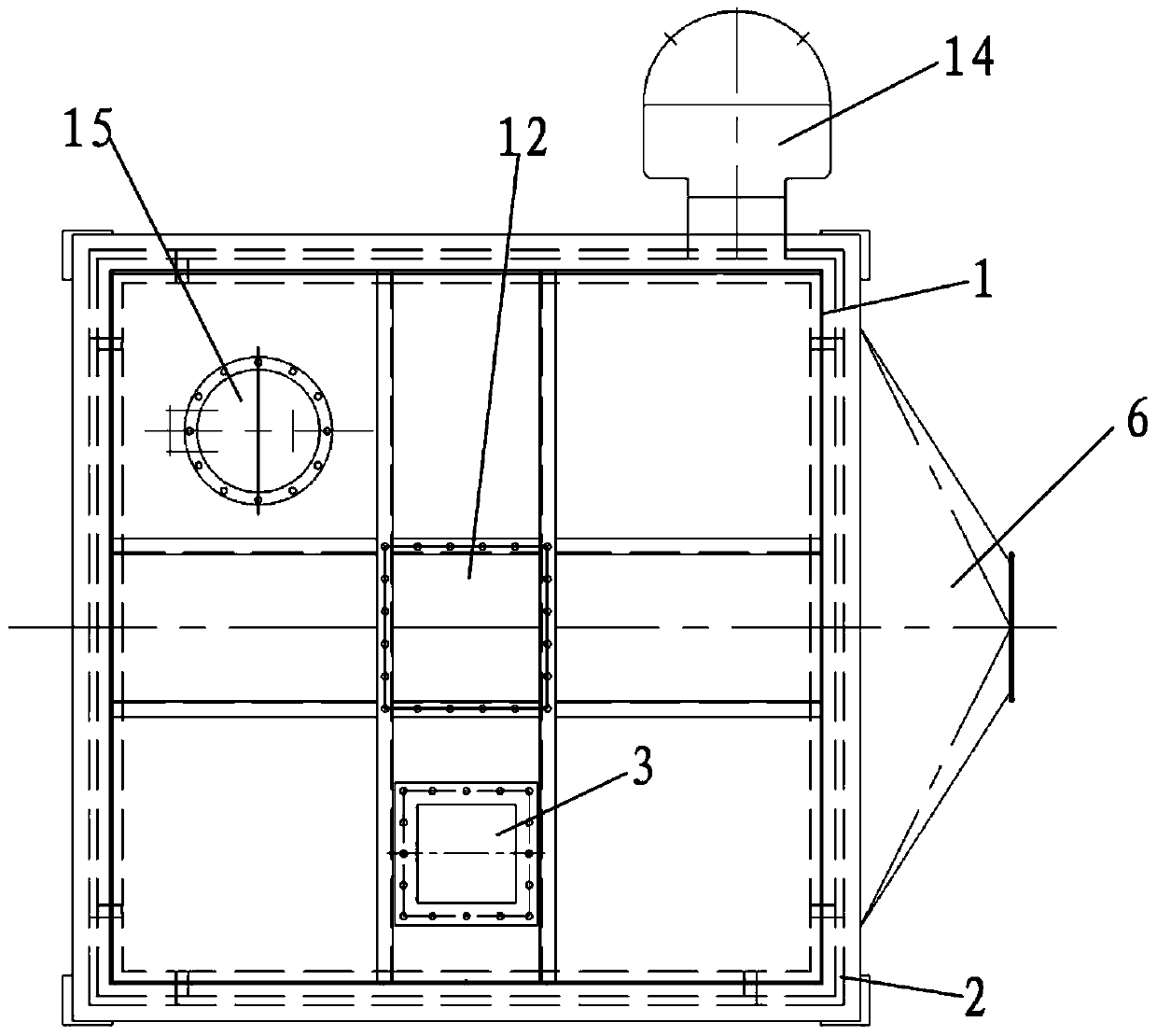

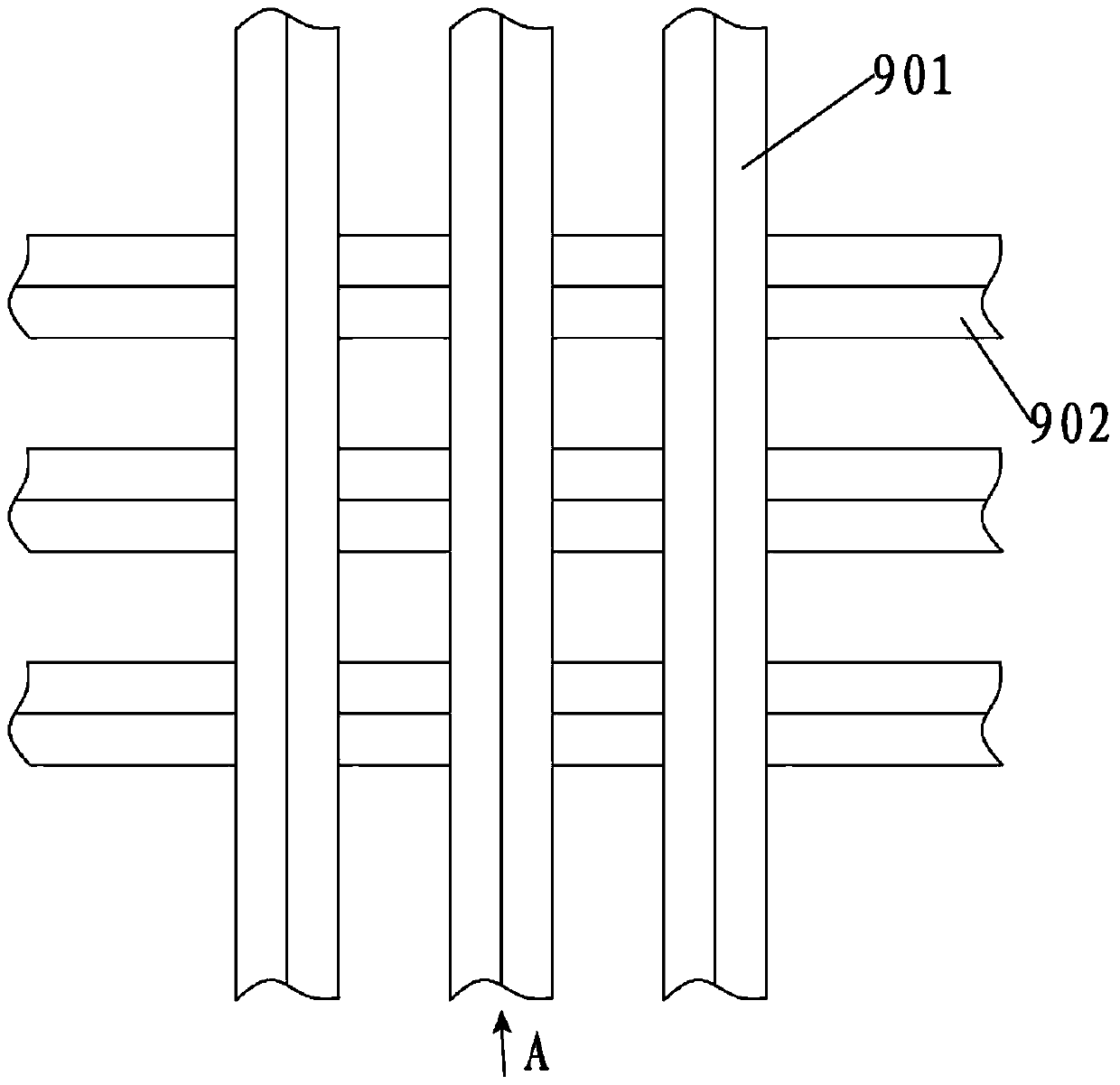

[0035] figure 1 A schematic diagram of the cooler structure. Such as figure 1 As shown, a vertical powder cooler includes a vertically arranged casing 1, the top of the casing 1 has a feed port 3, and the bottom has a discharge port 4, and also includes a blanking grate 8, a material puller 7 and distributor 9, the feeding grate 8 and the distributor 9 are arranged perpendicular to the falling direction of the material, the edge of the distributor 9 is fixed on the inner wall of the housing 1, and the feeding grate 8 is close to the feeding The port 3 is provided, and the material shifter 7 is above the blanking grate 8, and it communicates with the driving device 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com