System and method for controlling delivery of warehouse of steel deep processing industry

A control method and technology of a control system, which are applied in the warehouse delivery control system and its control field in the steel deep processing industry, can solve the problems of lack of understanding of information, neglect of steel allocation, and incompatibility of warehouse information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

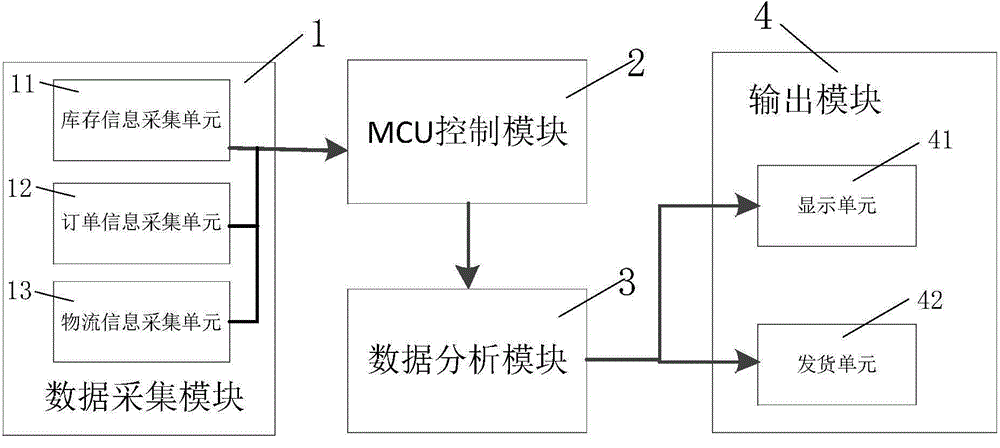

[0035] A warehouse delivery control system in the iron and steel deep processing industry. Combine below figure 1 The system provided in this embodiment will be described in detail.

[0036] figure 1 Among them, the present invention provides a warehouse delivery control system for steel deep processing industry, which includes a data acquisition module 1, a data analysis module 3, an MCU control module 2 and an output module 4;

[0037] The data collection module 1 is used to collect inventory information, order information and logistics information;

[0038] The MCU control module 2 receives the inventory information, order information and logistics information, and sends the inventory information, order information and logistics information to the data analysis module 3;

[0039] The data analysis module 3 analyzes the appropriate delivery information according to the received inventory information, order information and logistics information, and then sends the delivery...

Embodiment 2

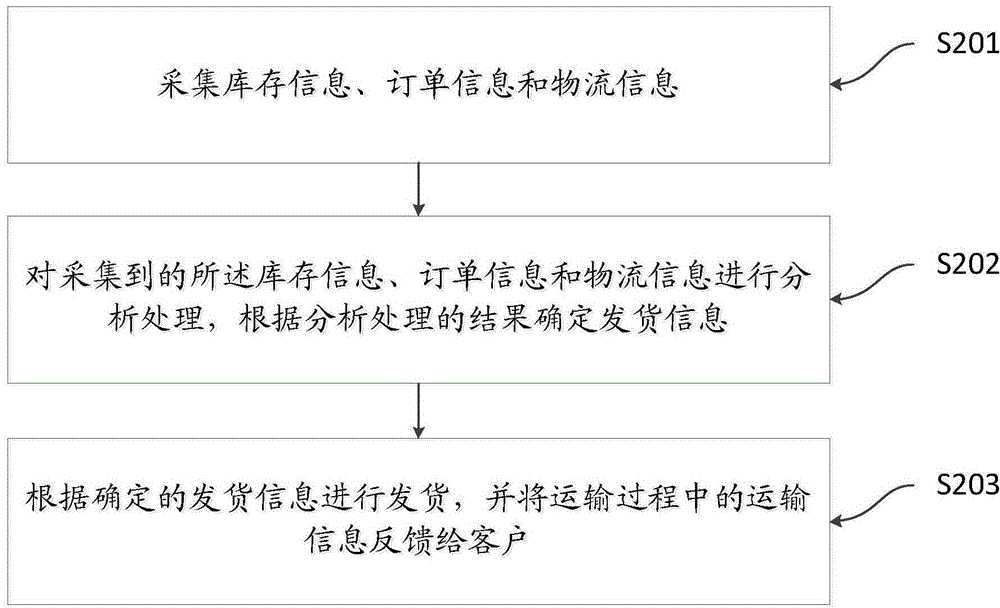

[0046] A method for controlling delivery from a warehouse in the iron and steel deep processing industry. Attached below figure 2 The method provided in this embodiment will be described in detail.

[0047] figure 2 Among them, the present invention provides a control method for warehouse delivery in the iron and steel deep processing industry, which includes the following steps:

[0048] S201. Collect inventory information, order information and logistics information;

[0049] S202. Analyzing and processing the collected inventory information, order information and logistics information, and determining delivery information according to the analysis and processing results;

[0050] S203 , deliver the goods according to the determined delivery information, and feed back the transportation information during the transportation to the customer.

[0051] The inventory information includes location information of each warehouse, type information of steel products in the wareho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com