Bionic suspension fork

A front fork and shock absorber technology, used in steering mechanisms, bicycle accessories, transportation and packaging, etc., can solve problems such as reducing riding safety, and achieve the purpose of increasing stretch, improving riding stability, and facilitating decomposition and transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

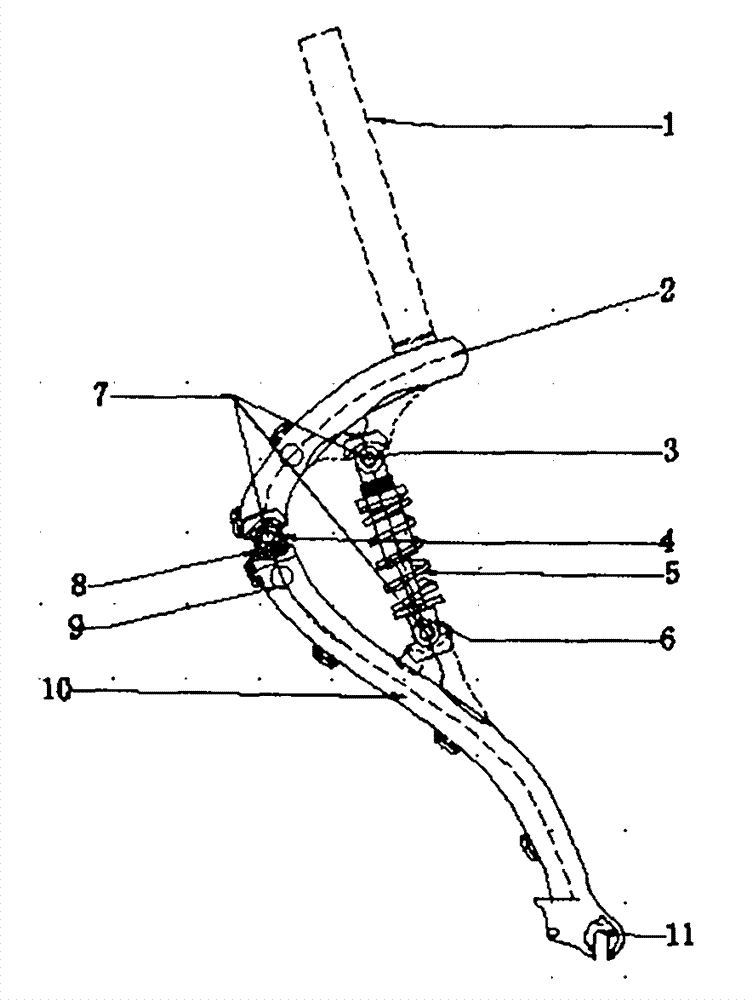

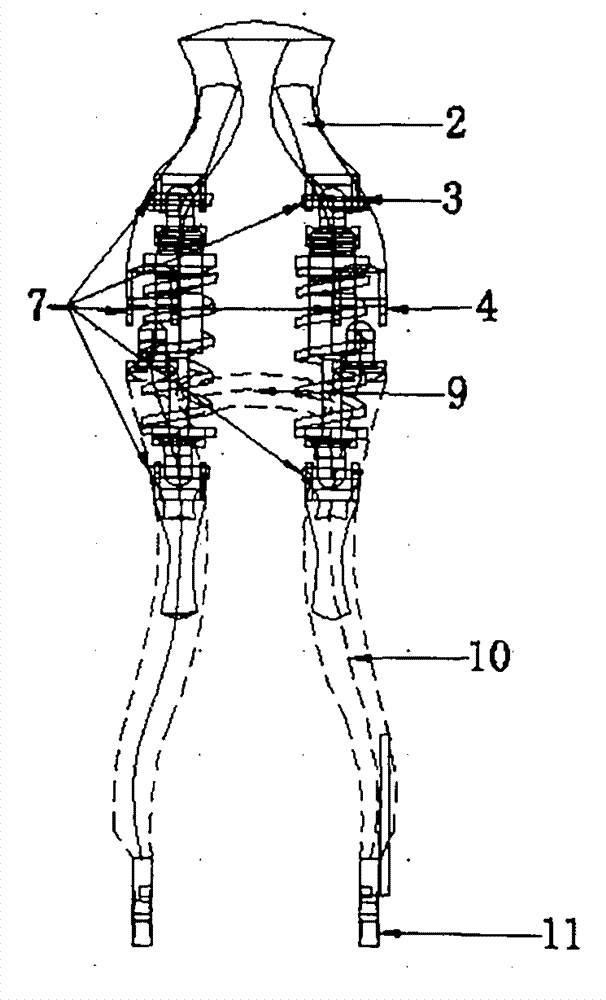

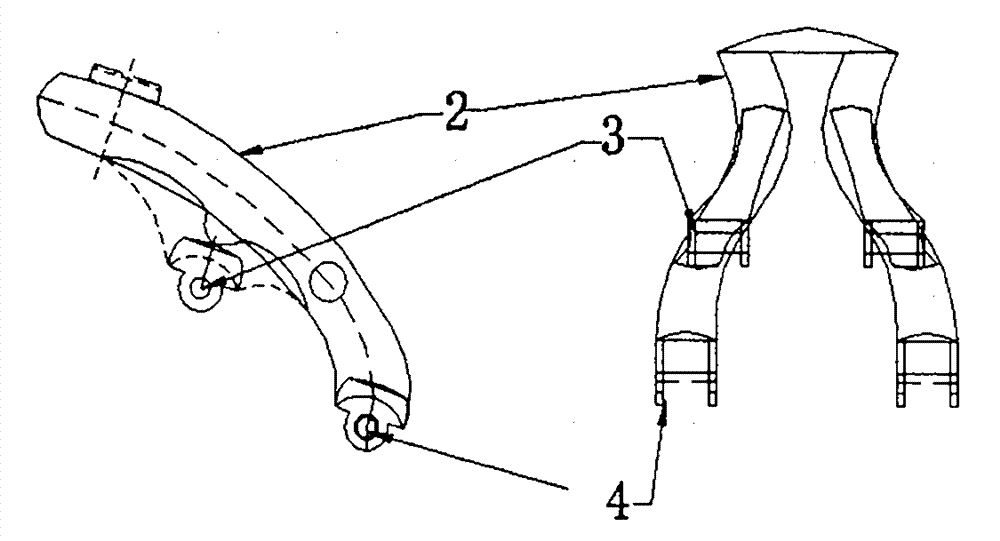

[0013] A bionic shock-absorbing front fork, comprising a front fork riser 1, a front fork crown 2, two shock absorbers 5, two front fork legs 10, six connecting frames 3, two connecting seats 8, six A lock bolt 7. The connection method is formed by connecting each part with a specific angle between parts. The front fork standpipe 1 is connected with the front fork crown 2 as a whole, the four connecting frames 3 are integrated with the front fork crown 2, and the two connecting frames 3 and one end of the two shock absorbers 5 on the front fork crown are used Two locking bolts 7 are connected. The other ends of the two shock absorbers 5 are connected with the two connecting frames 6 on the two front fork legs 10 with two locking bolts 7, and the two front fork legs 10 are connected with the bracket 9 as a whole. The other two connecting frames 4 of the front fork crown 2 are connected with two connecting seats 8 on the fork legs of the front fork with two locking bolts 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com