A pulse sand fracturing system and its control method

A sand fracturing, pulsed technology, applied in earth-moving drilling, production fluids, wellbore/well components, etc., can solve problems such as the effective switching limit of sand ratio, reducing equipment service life, performance condition restrictions, etc. The probability of mechanical failure and the degree of mechanical wear, the effect of improving the flow conductivity and ensuring the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

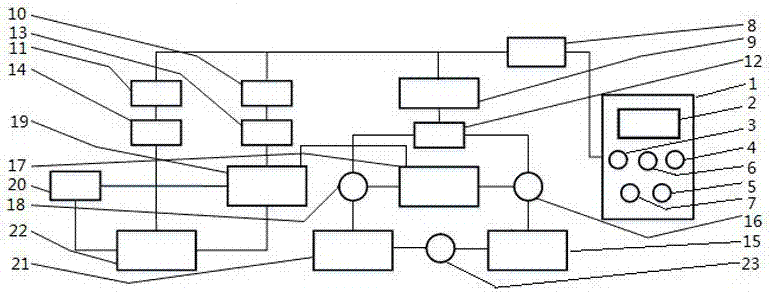

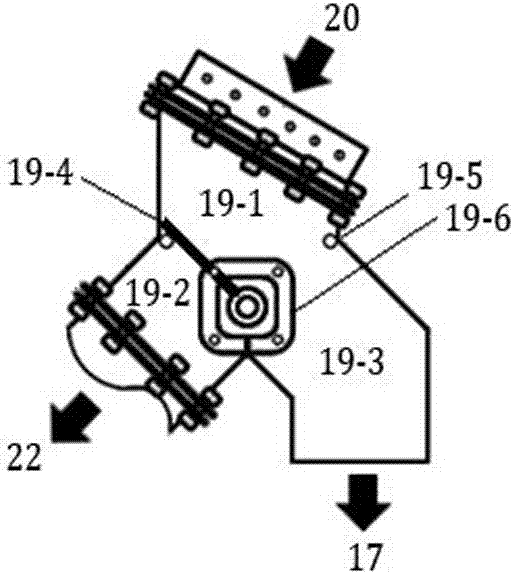

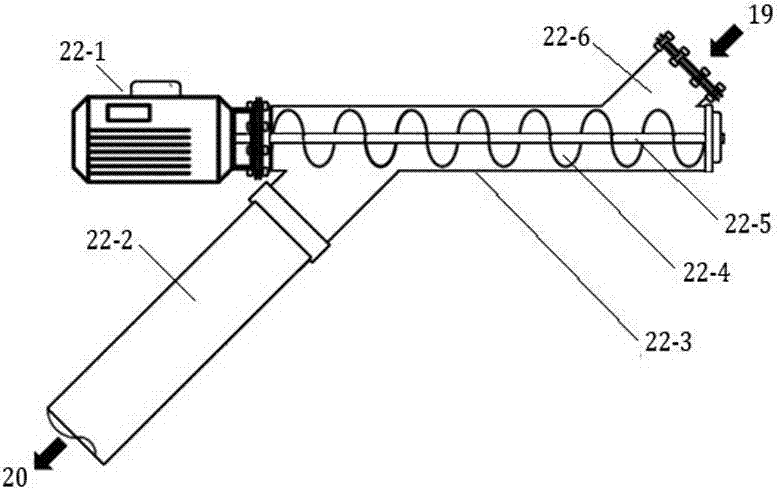

[0038] Such as Figure 1~5 As shown, the present invention is a pulse sand fracturing system, which includes a sand bucket 20, a fracturing fluid tank 21, a sand fluid mixing cylinder 17 and a fracturing pump unit 15 arranged on a sand mixing vehicle. Wherein: the sand bucket 20 is equipped with proppant a, and the fracturing fluid tank 21 is equipped with fracturing fluid b; the sand bucket 20 and the fracturing fluid tank 21 are respectively connected to the sand fluid mixing cylinder 17 through pipelines, and the sand fluid mixing cylinder 17 and The fracturing fluid tanks 21 are respectively connected to the fracturing pump unit 15 through pipelines, and the fracturing pump unit 15 alternately pumps the pure fracturing fluid b and the sand-carrying fluid c to the formation m, forming a pulsed sand-adding fracturing system. The innovation of the present invention is:

[0039] - A proppant circulation loop is connected in parallel to the pipeline between the sand bucket 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com