Laser receiving optical axis and visible light optical axis parallelism adjustment system and adjustment method

A laser receiving and visible light technology, applied in the field of optical detection, can solve the problems of low precision, poor stability, large environmental influence factors, etc., and achieve the effect of improving precision and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

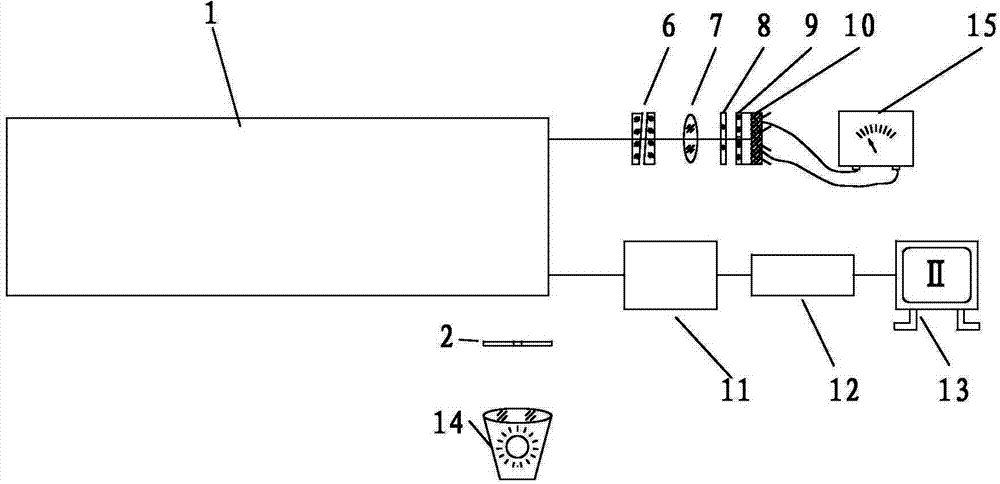

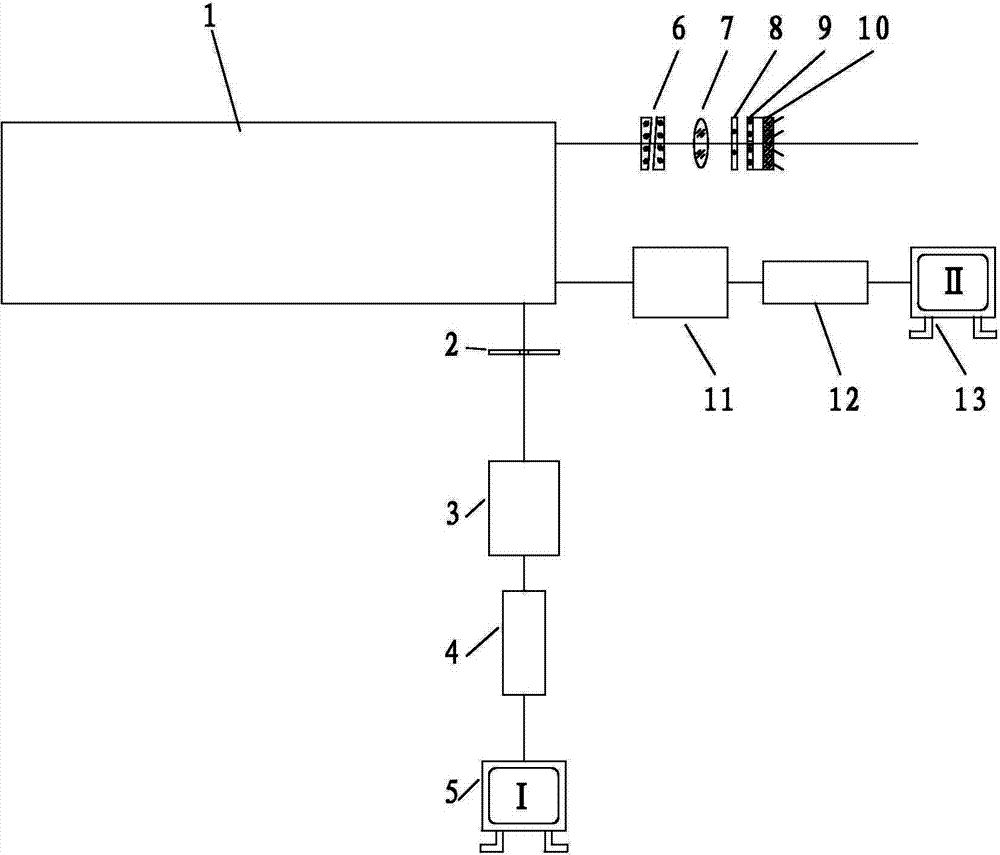

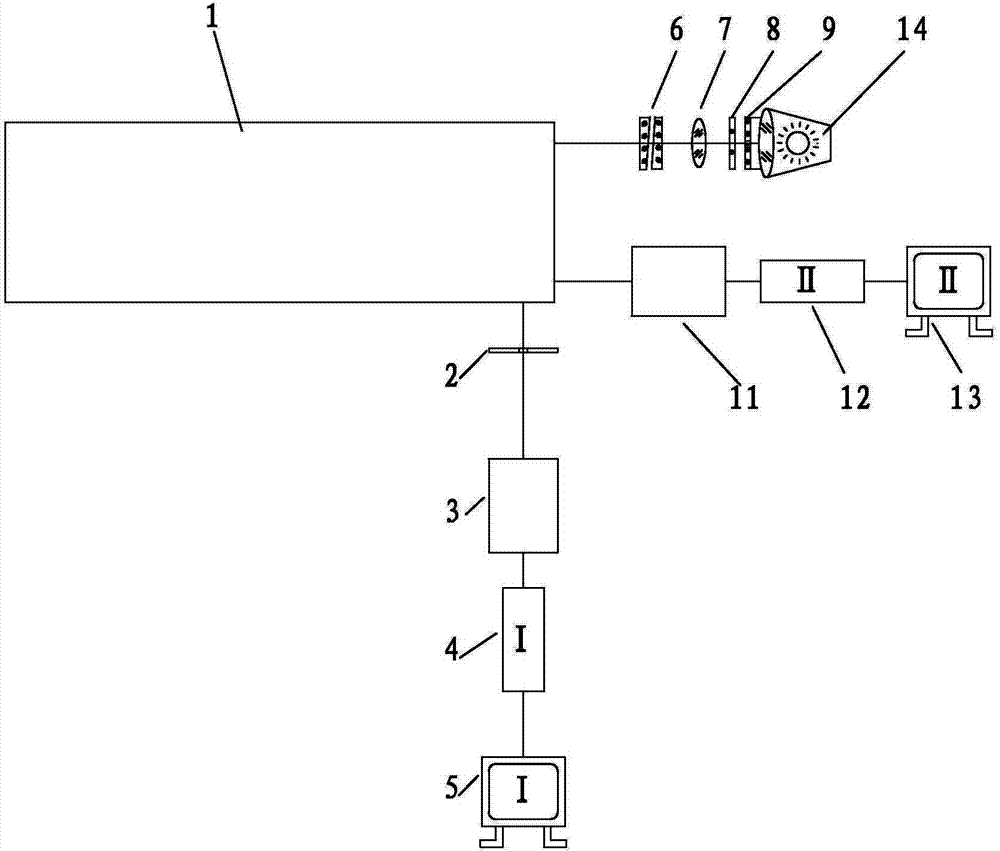

[0043] refer to figure 2 and image 3 As shown, the system for adjusting the parallelism between the laser receiving optical axis and the visible light optical axis in this embodiment includes the following components:

[0044] A reflective collimator 1 placed on a fixed workbench;

[0045]The laser receiving channel, aligned with the reflective collimator 1, includes a coaxially arranged optical wedge 6, a receiving objective lens 7, an optical filter 8, a small hole glass 9 and an avalanche tube 10; the optical wedge 6 has two pieces; because The pinhole glass 9 and the avalanche tube 10 are usually made together, and the relative position of the two is particularly important, which determines whether the imaging can fall on the photosensitive surface of the avalanche tube 10. When adjusting, it is necessary to use a spotlight 14 to replace the The avalanche tube 10 is described above, so it is only necessary to replace the avalanche tube 10 during adjustment, and continu...

Embodiment 2

[0057] Based on the above-mentioned calibration system, the present invention also provides a method for calibrating the parallelism between the laser receiving optical axis and the visible light axis. On the fixed workbench, the reticle 2 is set as a cross reticle, and the front of the reticle 2 is placed sequentially as the achromatic lens 3 for adjustment, the first CCD camera 4 and the first display 5, and the cross reticle 2 The axial distance with the achromatic lens 3 is the object distance of the achromatic lens, and the axial distance between the achromatic lens 3 and the first CCD camera 4 is the back intercept of the achromatic lens; Align the type collimator 1; then perform adjustment, the adjustment specifically includes the following steps:

[0058] S1: The visible light channel is electronically divided; when the visible light channel includes such as figure 2 When the lens 11, the second CCD camera 12 and the second display 13 are shown, in the step S1, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com