A high-voltage equipment box for a rail vehicle

A technology for high-voltage equipment boxes and rail vehicles, applied in the field of rail vehicles, can solve the problems of increasing aerodynamic noise, complex roof structure, influence of roof streamline structure, etc., so as to improve aerodynamic performance, reduce air resistance, and improve aerodynamic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

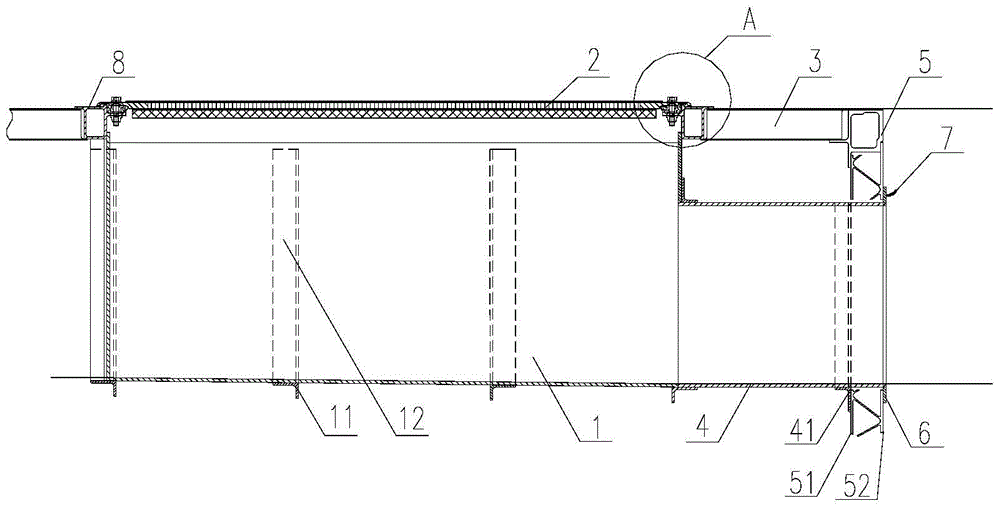

[0026] The core of the present invention is to provide a high-voltage equipment box for rail vehicles, which can realize the sunken installation of high-voltage equipment, and at the same time reduce the impact on the streamline structure of the roof, thereby reducing air resistance and aerodynamic noise, and improving the aerodynamic performance of the train .

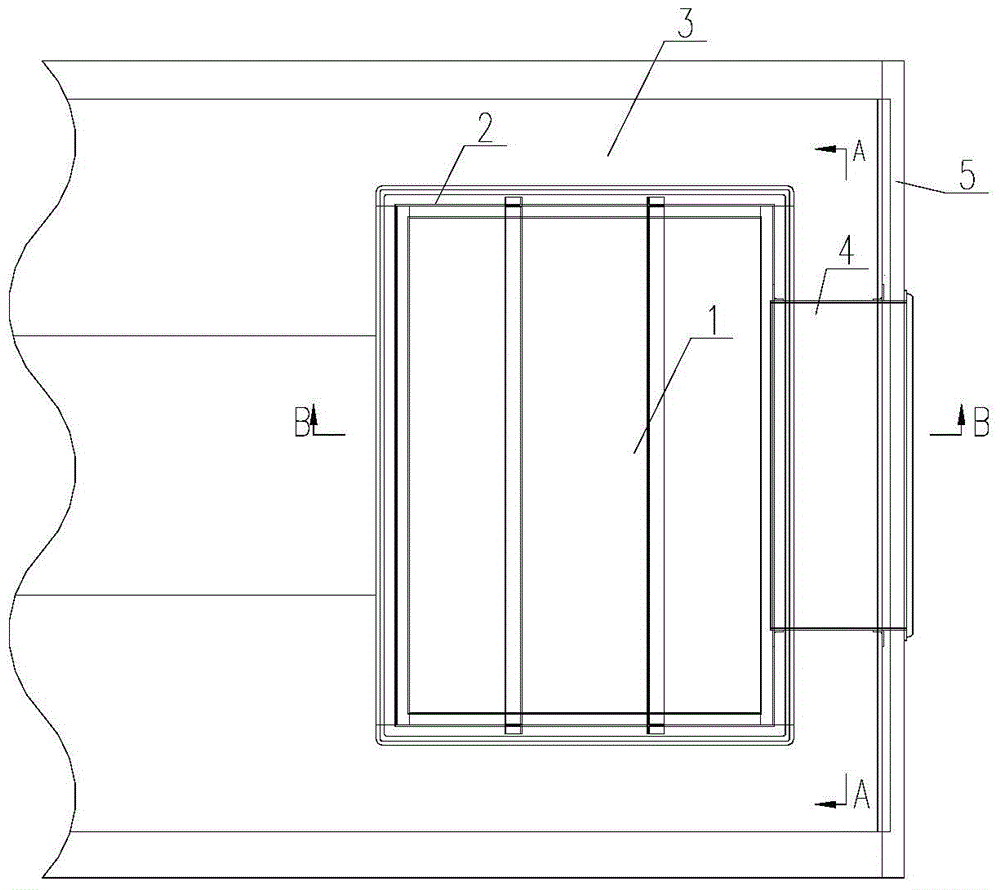

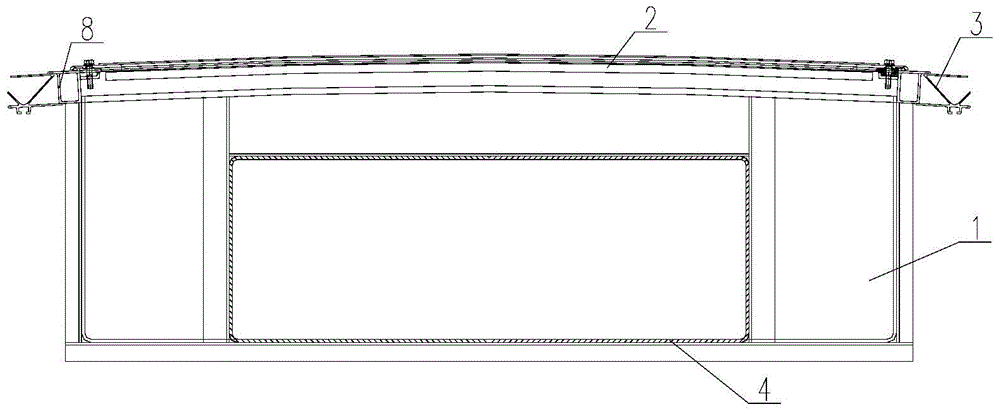

[0027] The present invention provides a high-voltage equipment box of a rail vehicle, which is arranged on the roof 3 of the rail vehicle, and specifically can be integrated on the roof 3, so as to realize "sinking" installation of high-voltage equipment.

[0028] Such as Figure 1-4 As shown, there is a high-voltage equipment box for installing high-voltage equipment on the roof 3 of the rail vehicle, including a box body 1 and a top cover 2 covered on the box body 1, and the box body 1 has a hollow space for accommodating high-voltage equipment. cavity, so that the high-voltage equipment can be installed in the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com