Railway vehicle and roof thereof

A rail vehicle and profile technology, applied in the field of rail vehicles, can solve problems such as noise inside the vehicle, the influence of source field noise, reduce the strength of the roof, and low space utilization, so as to simplify the structure of the car body, improve the strength of the car body, reduce the The effect of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

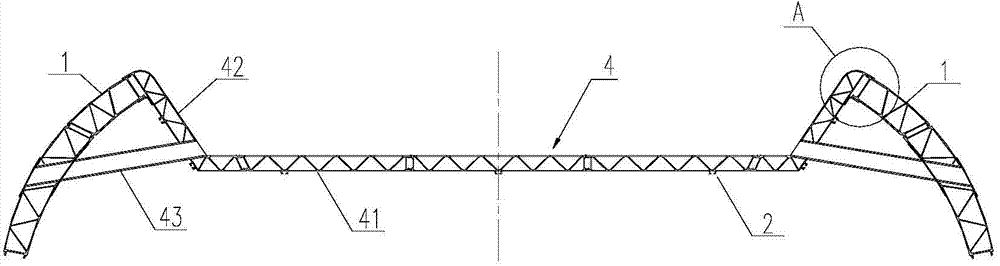

[0030] The core of the present invention is to provide a rail vehicle and its roof, which can realize the sunken installation of current collectors and air conditioners, and at the same time reduce the impact on the streamline structure of the roof, thereby reducing air resistance and aerodynamic noise, and lifting the train. aerodynamic performance.

[0031] The vehicle roof of the present invention will be introduced below with reference to the accompanying drawings, so that those skilled in the art can accurately understand the technical solution of the present invention.

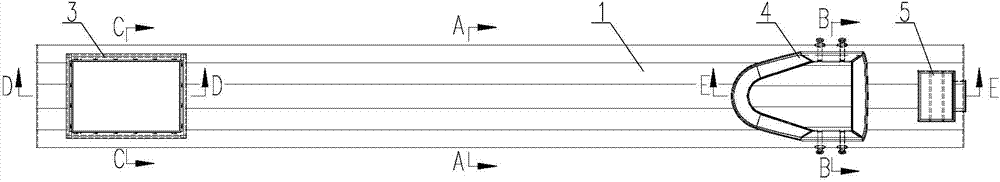

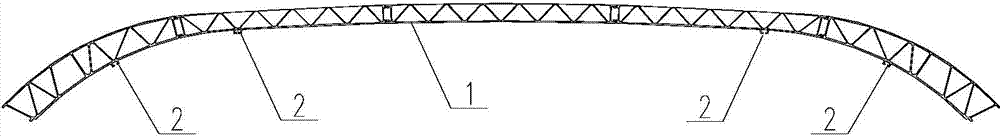

[0032] Such as figure 1 with figure 2 As shown, the roof 1 of the rail vehicle in the present invention includes several hollow profiles, each hollow profile extends longitudinally to cover the longitudinal direction of the entire car body; each hollow profile is spliced horizontally to form the entire roof 1. Specifically, five hollow profiles can be spliced to form the entire roof 1, and a hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com