Reactive compensation system

A compensation system and control system technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, AC network circuits, etc., can solve problems such as inability to compensate reactive power, many links of manual participation, and short service life of capacitors , to achieve the effect of good practicability and high precision reactive power compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

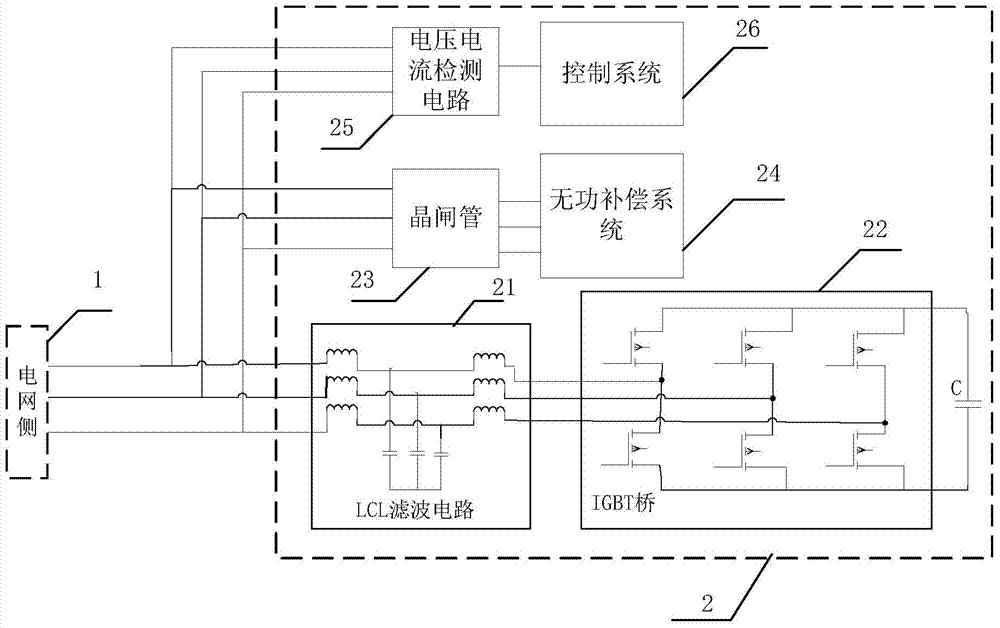

[0015] see figure 1 , a reactive power compensation system 2 of the present invention is externally connected to the power grid side 1, and the reactive power compensation system 2 includes an LCL filter circuit 21, an IGBT bridge 22 and a capacitor C sequentially connected to the power grid side 1, and a thyristor connected to the power grid side 1 in sequence 23 and a reactive power compensation unit 24, a voltage and current detection circuit 25 and a control system 26 sequentially connected to the grid side 1, wherein:

[0016] Both ends of the capacitor C are connected to the IGBT bridge 22;

[0017] The voltage and current detection circuit 25 collects voltage signals and current signals on the grid side, and transmits them to the control system 26; the control system 26 processes the received voltage signals and current signals, and sends control signals to the thyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com