Concrete levelling machine

A leveling machine and concrete technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of extending the telescopic length, deflection and deformation of a single telescopic rod, extending the working width, etc., to extend the telescopic length, ensure Flatness, the effect of extending the working width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

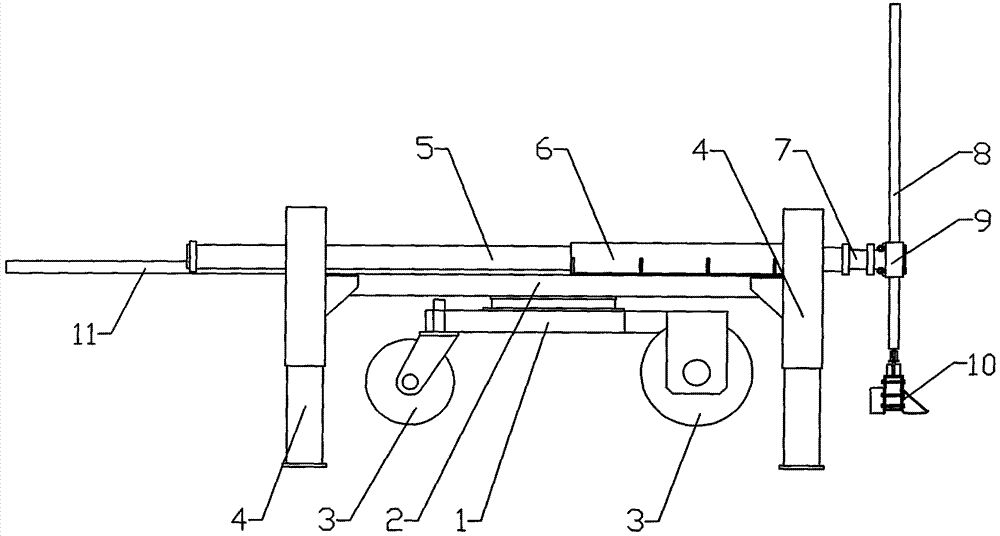

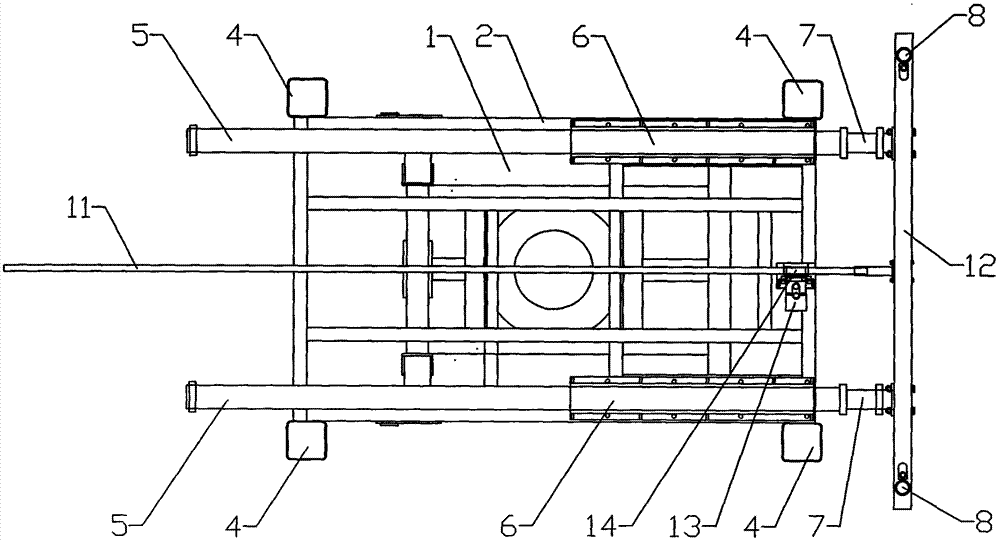

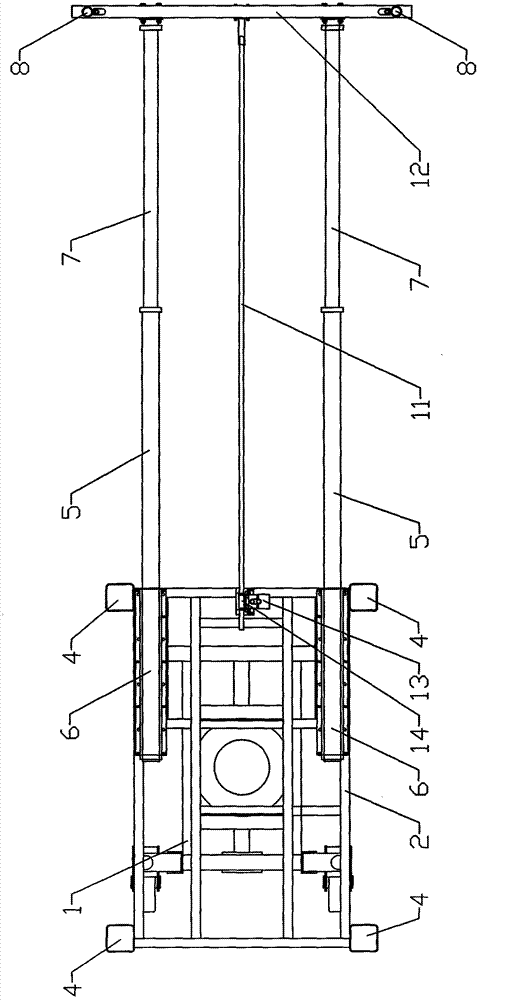

[0023] Example: as attached figure 1 And attached figure 2 As shown, the concrete leveling machine includes a chassis 2, the bottom of the chassis 2 is provided with a frame 1, the bottom of the frame 1 is provided with walking wheels 3, and the two sides of the chassis 2 are respectively provided with support seats 6 , the support base 6 is provided with a telescopic rod, the front portion of the telescopic rod is provided with a leveling head 10, the leveling head 10 is an existing leveling head, and the chassis 2 is provided with A drive device that drives the movement of the telescopic rod.

[0024] The front end of the telescoping rod is fixedly connected with a connecting sleeve 9, and the connecting sleeve 9 is arranged vertically. The connecting sleeve 9 is provided with a supporting rod 8, and the leveling head 10 is located at the lower end of the supporting rod 8.

[0025] A connecting rod 12 is arranged between the front ends of the two telescopic rods, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com