Telescopic pipe set, concrete distributing machine and trolley

A technology of telescopic tubes and tube groups, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of long time, workload and labor intensity, and achieve a simplified structure, meet construction needs, and be easy to choose. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

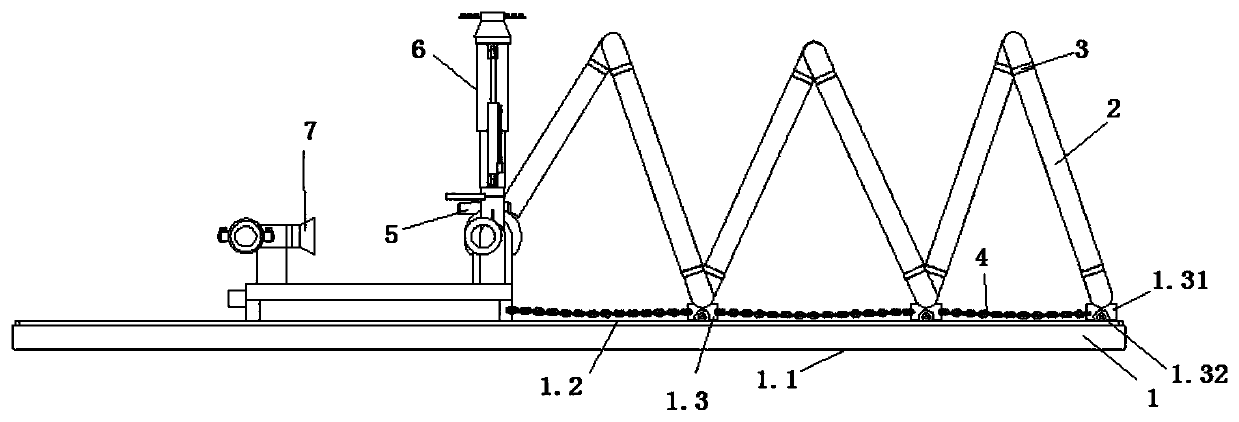

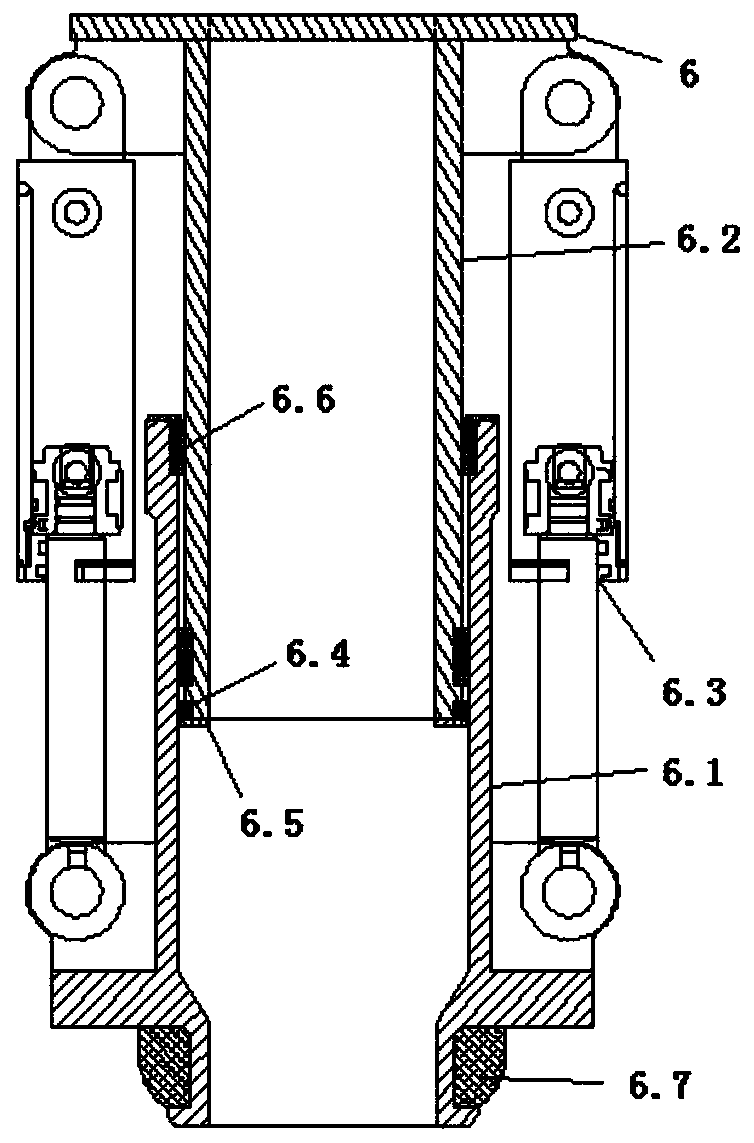

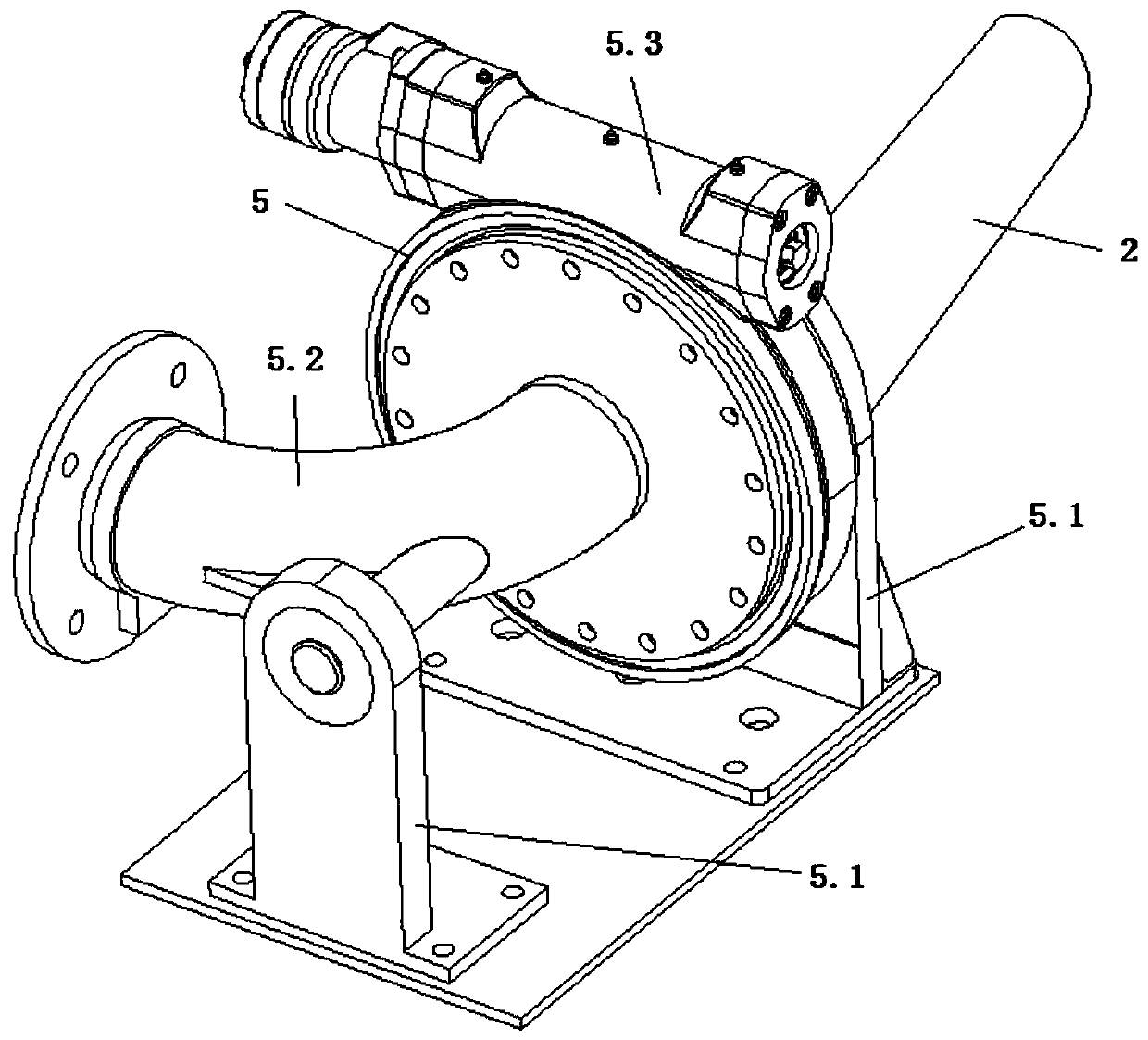

[0038] A telescopic tube group, see figure 1 , including a fixed bracket 1, a tube group 2 and a telescopic tube 6; the tube group 2 is slidably arranged on the fixed bracket 1, and the telescopic tube 6 is connected to the tube group 2, the details are as follows:

[0039] The tube group 2 includes at least two stretchable single tubes arranged in series, and the single tube may be composed of multiple U-shaped pump tubes and straight tubes; the adjacent single tubes are flexibly connected by a connecting piece 3; the tubes Group 2 includes a plurality of highest points on plane A and a plurality of lowest points on plane B, and plane A and plane B are parallel to each other.

[0040] The connecting piece 3 is a combination of a pipe clip and a sealing ring.

[0041] The fixed bracket 1 includes a base plate 1.1 and a slide rail 1.2 arranged on the base plate 1.1, and a single tube in the tube group 2 is slidably arranged on the slide rail 1.2 through a supporting trolley 1....

Embodiment 2

[0051] The difference between embodiment 2 and embodiment 1 is that the fixed bracket 1 includes a fixed bottom plate 1.4, a fixed top plate 1.5 and a C-shaped guide rail 1.6 arranged on the fixed top plate 1.5, see Figure 4 . The fixed top plate 1.5 is located above the fixed bottom plate 1.4, and the single tube in the tube group 2 is slidably arranged on the C-shaped guide rail 1.6 through the T-shaped movable group 1.7. The T-shaped movable group 1.7 can drive the whole tube group 2 to slide along the C-shaped guide rail 1.6 to realize expansion and contraction. The power of sliding can be mechanical (oil cylinder, cylinder, etc.), also can be manual. T-shaped movable group 1.7 can be T-shaped slide block, also can be block and pulley.

Embodiment 3

[0053] A concrete placing machine, comprising the telescopic tube group as described in embodiment 1 or embodiment 2, the whole telescopic tube group is set on the concrete placing machine trolley, and the trolley drives the entire telescopic tube group to move back and forth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com