Distributor for tractor

A technology for tractors and distributors, applied in mechanical equipment, fluid pressure actuating devices, servo motor components, etc., can solve the problems of easy pollution of asbestos pads, easy wear of valve cores, etc., to avoid oil leakage, avoid wear, and improve The effect of job reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

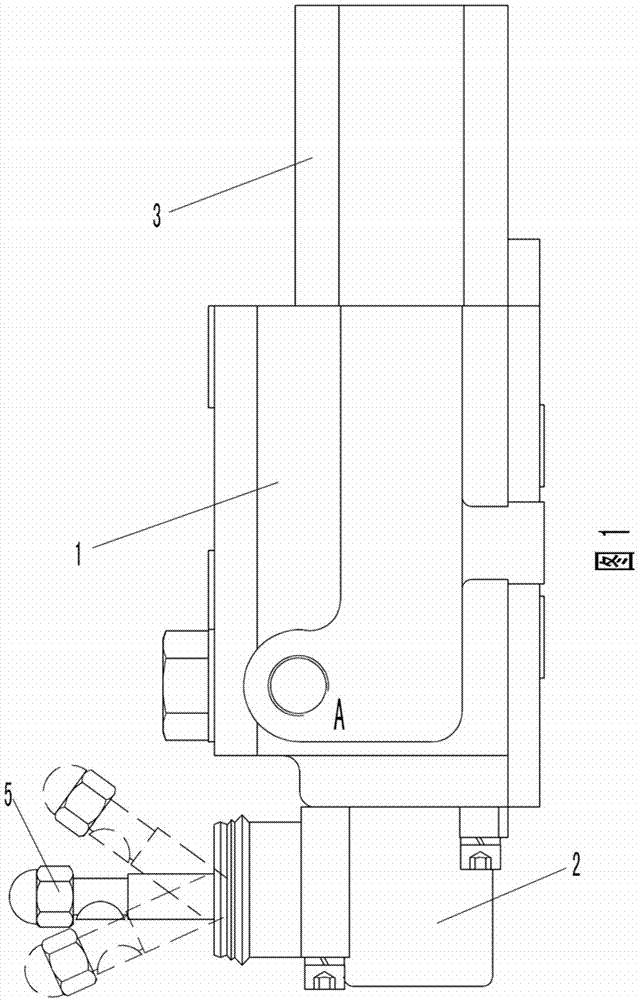

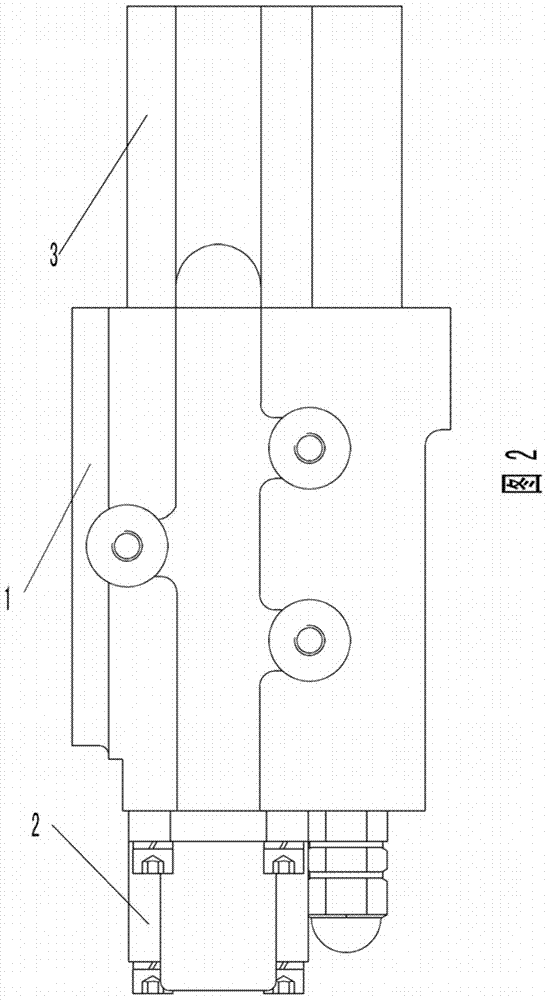

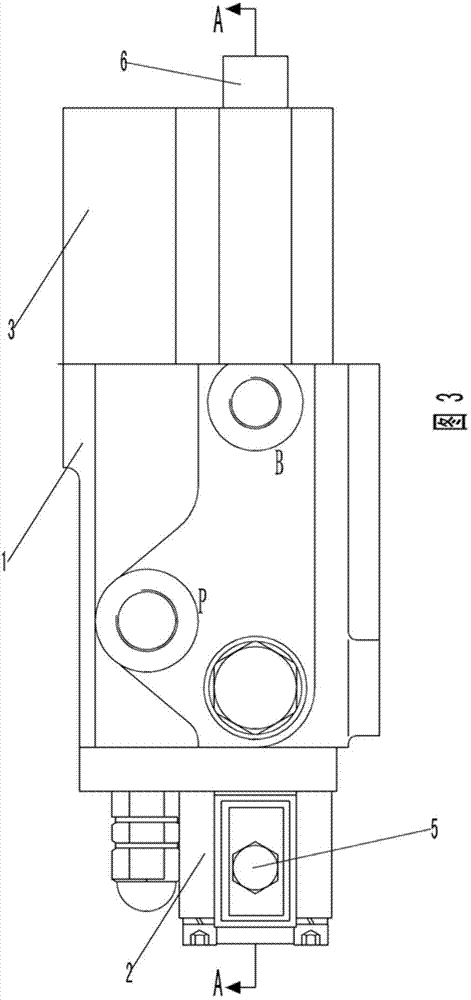

[0044] See attached Figure 1-9 , the distributor for the tractor of the present invention comprises a valve body 1, a front cover 2 and a rear cover 3; the valve body 1 is provided with a valve stem 4, and the first end of the valve stem 4 extends into the Inside the rear cover 3, the second end of the valve stem 4 extends into the front cover 2; the front cover 2 is provided with a handle 5; one end of the handle 5 extends into the front cover 2 and engages with the valve stem 4 so that the valve stem 4 can be pulled to move linearly along the axial direction of the valve stem 4 by pulling the handle 5; the other end of the handle 5 protrudes from the front cover 2 to facilitate manual wrenching;

[0045] A through hole 301 penetrating through the back cover 3 is provided on the end surface of the end of the back cover 3 away from the valve body 1, and a balance guide rod 6 is arranged in the through hole 301; the balance guide rod The first end of 6 protrudes outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com