Portable fast-assembly big bed guardrail

A portable and guardrail technology, applied in the direction of beds, other seating furniture, home appliances, etc., can solve the problems of portability, inconvenience, large space occupation, complex cost, etc., and achieve the effect of simple structure, low processing cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

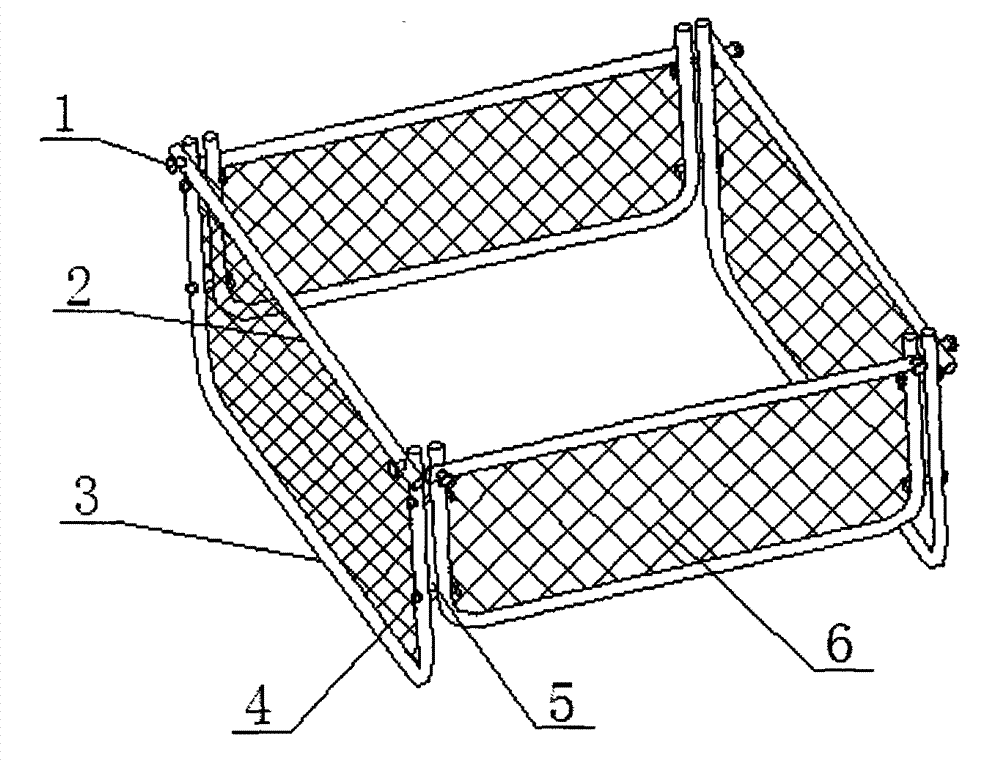

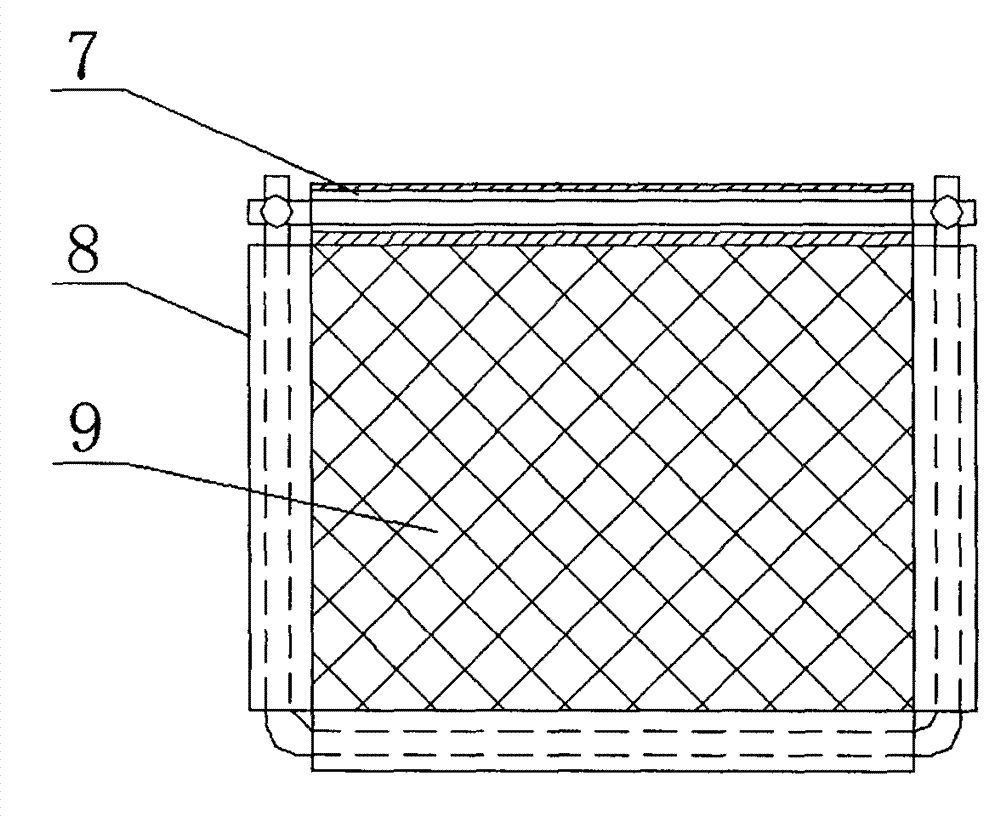

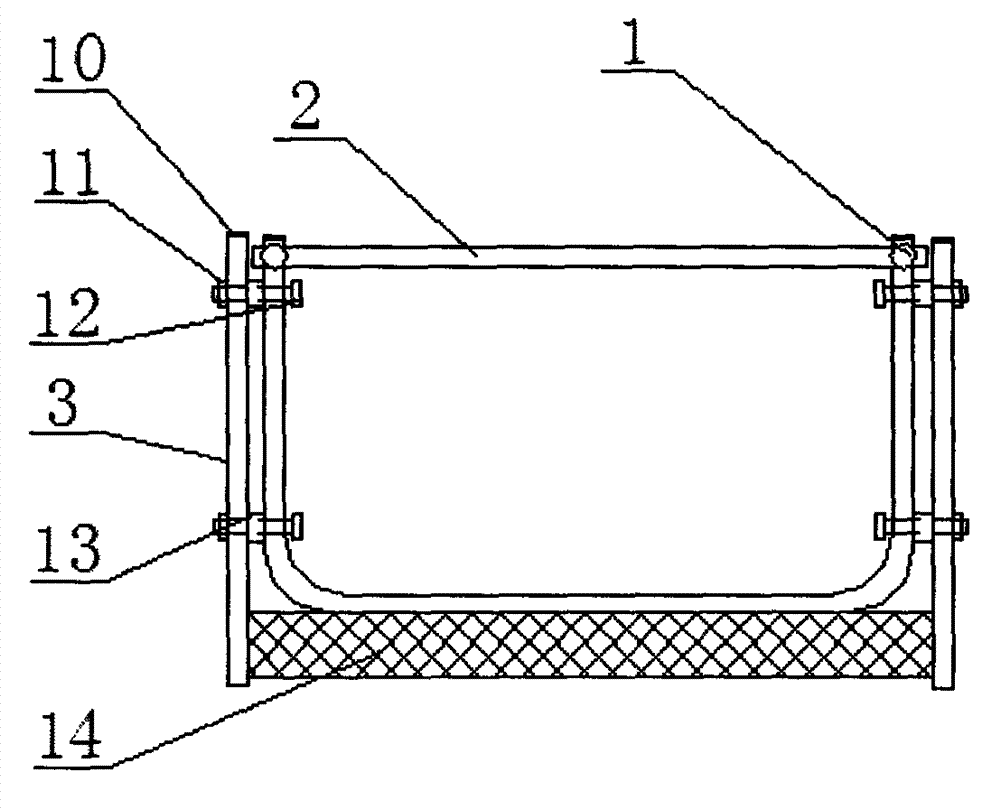

[0037] Embodiment 1: A portable quick-loading large bed guardrail, including four groups of interconnected single-sided guardrails 15 and a protective net 6 installed on the single-sided guardrail 15, the single-sided guardrail 15 includes a U-shaped fixed rod 3 and a Font movable rod 2, fixed rod 3 is made up of two L-shaped rods and adjusting rod 17, and the corner of each L-shaped rod is provided with rounded corners, and movable rod 2 is made up of two inline rods and adjusting rod 17, in fixed Both the rod 3 and the movable rod 2 are provided with threaded holes, and the movable rod 2 is positioned at the outside of the fixed rod 3, and the fixed rod 3 and the movable rod 2 are connected into a font by the knob 1 installed in the threaded hole. A plastic plug 10 is installed at the end of the movable rod 2, and the protective net 6 includes a mesh body 9 in the middle and surrounding cloth 8, and a sleeve opening 7 is provided on the surrounding cloth 8, and the fixed rod ...

Embodiment 2

[0038] Embodiment 2: The difference from the above embodiment is that in this embodiment, V-shaped spring clips 18 are built in both ends of the adjustment rod 17, and the V-shaped spring clips 18 are provided with protrusions 19, and the two L-shaped rods are provided with Several circular holes 20, two L-shaped rods connect the protrusion 19 on the adjusting rod 17 through the circular holes 20 respectively, two inline rods are provided with several circular holes 20, and the two inline rods pass through the circular holes 20 respectively. Connect the protrusion 19 on the adjusting rod 17. The beneficial effects of this embodiment: By using different round holes 20 to cooperate with the protrusions 19, the overall size of the guardrail can be adjusted to suit different sizes of beds, and the guardrail can also clamp the mattress by adjusting the size of the guardrail.

Embodiment 3

[0039] Embodiment 3: The difference from the above-mentioned embodiment is that in this embodiment, both ends of the adjustment rod 17 are threaded, and corresponding threads are processed on the L-shaped rod and the straight rod, so that the adjustment rod 17 and the L-shaped rod It is directly connected with the straight rod through threads, the structure is simple, the cost is low, and it is easy to carry after being disassembled. At the same time, the installation is simple. The length of the rod 17 can be adjusted by screwing the L-shaped rod and the straight rod, and the size of the guardrail can be adjusted to make the guardrail Clamp the mattress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com