Metal-welded sealed convex double-vacuum-layer glass with installing holes and edges sealed by sealing grooves and strips

A sealing strip groove and metal welding technology, applied in the field of glass deep processing, to achieve high sealing strength and airtightness, eliminate variable deformation, and increase heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

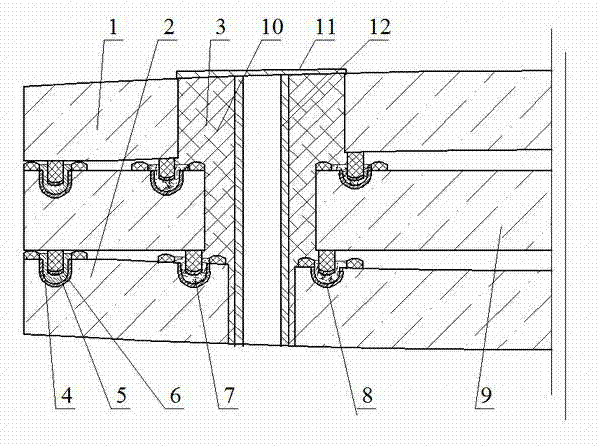

[0046] Embodiment: Referring to the accompanying drawings, the convex double vacuum laminated glass consists of an upper convex glass 1 , an intermediate glass 9 and a lower convex glass 2 . The production method is as follows: First, cut three pieces of flat glass of the required size according to the shape and size of the vacuum glass to be produced, and drill a through hole at the corner of the upper glass 1, the middle glass 9 and the lower glass 2 as the air outlet ( Mounting hole) 3, wherein the through hole on the upper glass 1 is larger than the through hole on the middle glass 9, and the sealing groove 6 is set on the upper surface periphery of the middle glass 9 and the lower glass 2 and the periphery and the corresponding place of the suction port 3, and the Three pieces of glass are ground, chamfered, cleaned, and dried; secondly, the sealing strip 5 is prepared by spraying on the periphery of the lower surface of the upper glass 1 and the middle glass 9, the periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com