Patents

Literature

73results about How to "Prevent air tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum glass laminated at high temperature and production method thereof

InactiveCN104743842AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingHeating furnace

The invention relates to a vacuum glass laminated at high temperature, which comprises an upper glass and a lower glass, the upper glass and the lower glass are plane glass or convex glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder or a metal solder in a vacuum furnace, an enclosing vacuum layer is formed between the upper glass and the lower glass, and the supporters with lattice arrangement are arranged in the vacuum layer. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and usage life is increased.

Owner:戴长虹

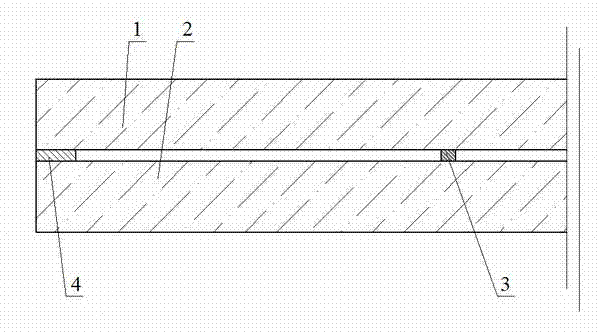

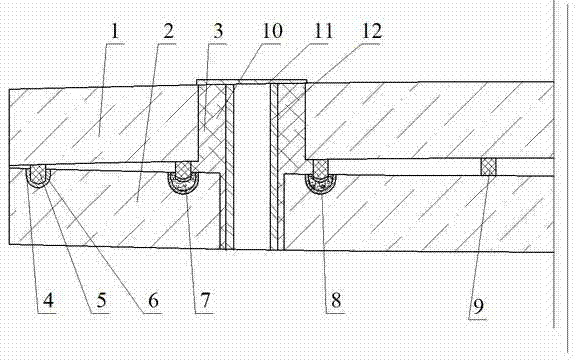

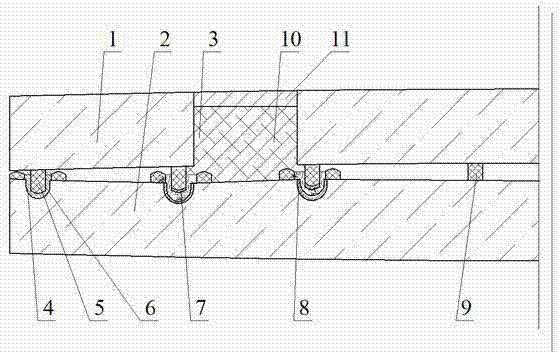

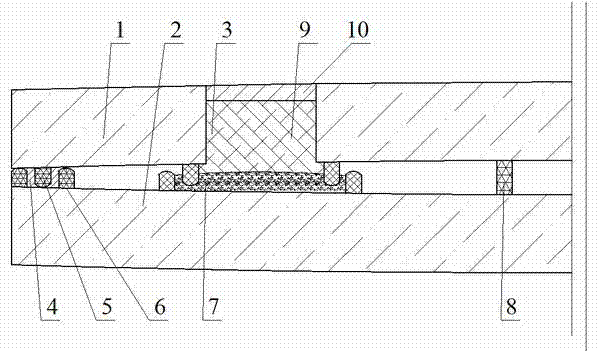

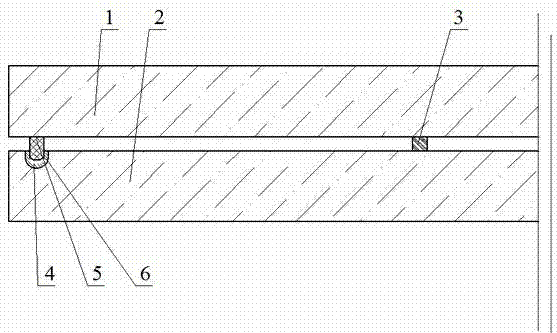

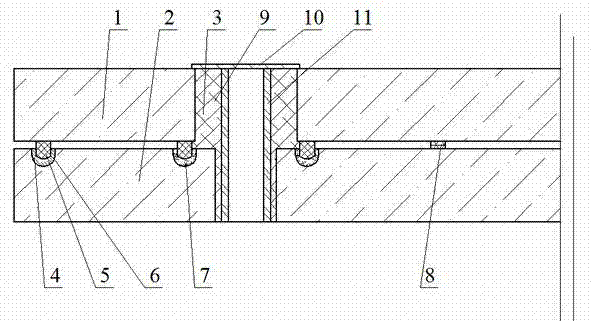

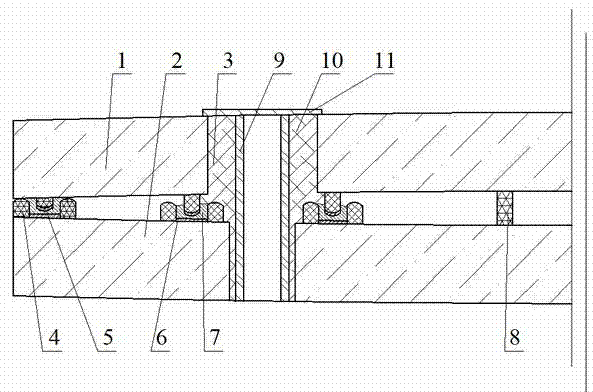

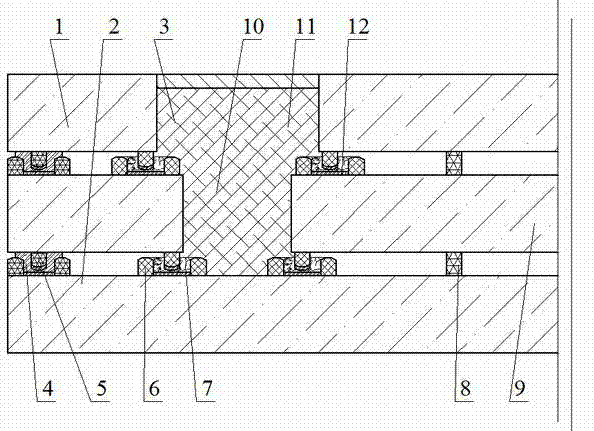

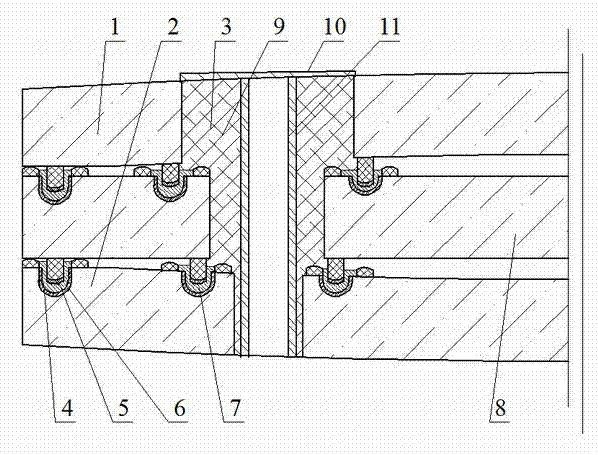

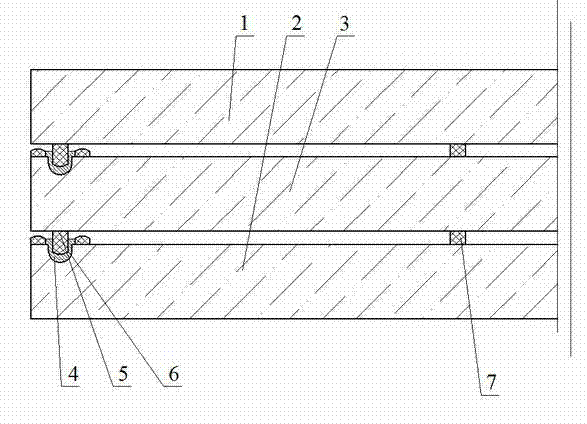

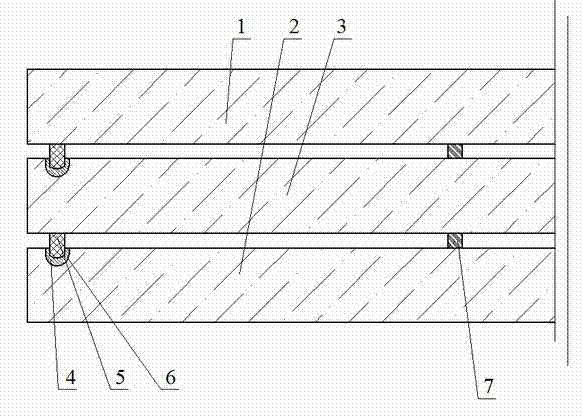

Metal-welded plain vacuum glass provided with edges sealed by sealing strips and manufacturing method thereof

Metal-welded plain vacuum glass provided with edges sealed by sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with at least one sealing strip; the periphery of the lower glass is provided with at least two sealing strips; the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; and after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

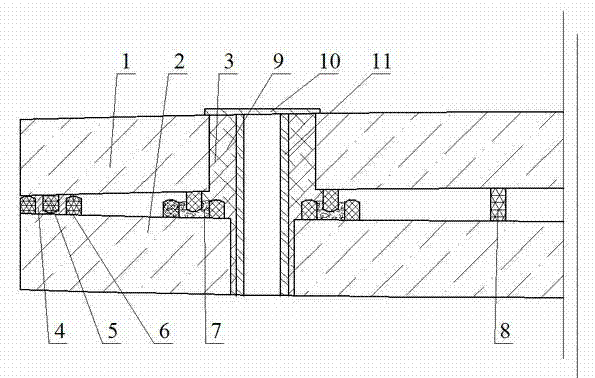

High-temperature-sheet-combination convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743825AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

InactiveCN104743805AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting holes. The peripheries of the upper glass and each air extracting hole are provided with sealing strips. Corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips. After being heated, the upper glass and the lower glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

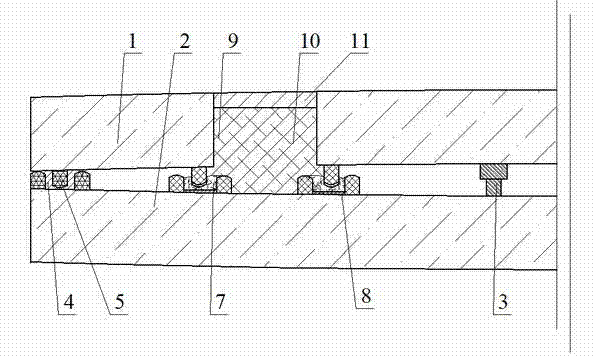

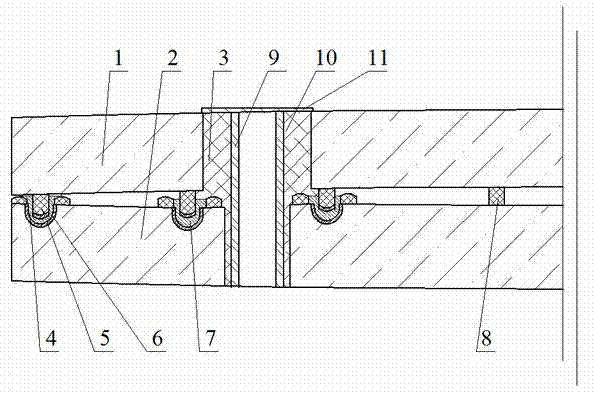

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the periphery of the upper glass is provided with sealing strips; corresponding positions of the periphery of the lower glass are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

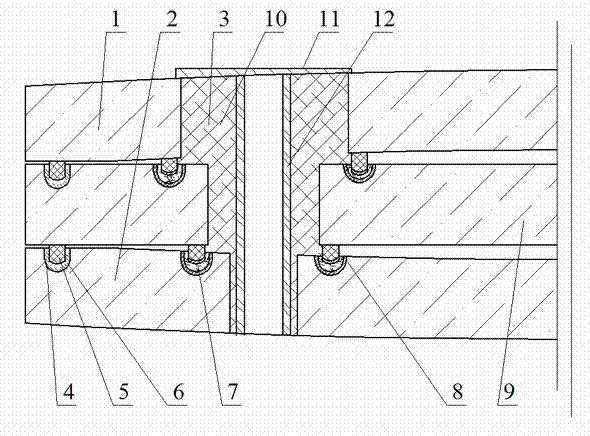

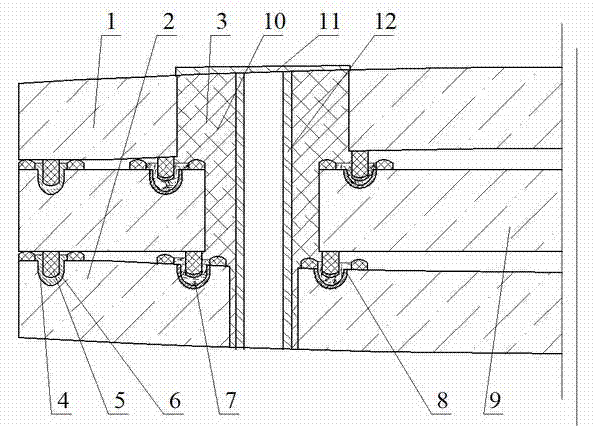

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and manufacturing method thereof

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: peripheries of the upper surfaces of the upper glass and the middle glass are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass are provided with the sealing grooves; after the three sheets of glass are rapidly heated, the peripheries of the three sheets of glass are welded under elevated pressure by metal solder in a vacuum furnace; and two vacuum layers are formed among the upper glass, the lower glass and the middle glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded sealed convex vacuum glass with edges and extraction openings sealed by sealing strips and production method thereof

InactiveCN104743850AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

The invention relates to a glass-welded sealed convex vacuum glass with edges and extraction openings sealed by sealing strips, which comprises an upper glass and a lower glass, 1-4 extraction openings are arranged on the upper glass, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are respectively provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

Glass-welded plain vacuum glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743832AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain vacuum glass with edges sealed by sealing grooves is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with sealing strips; the periphery of the lower glass is provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

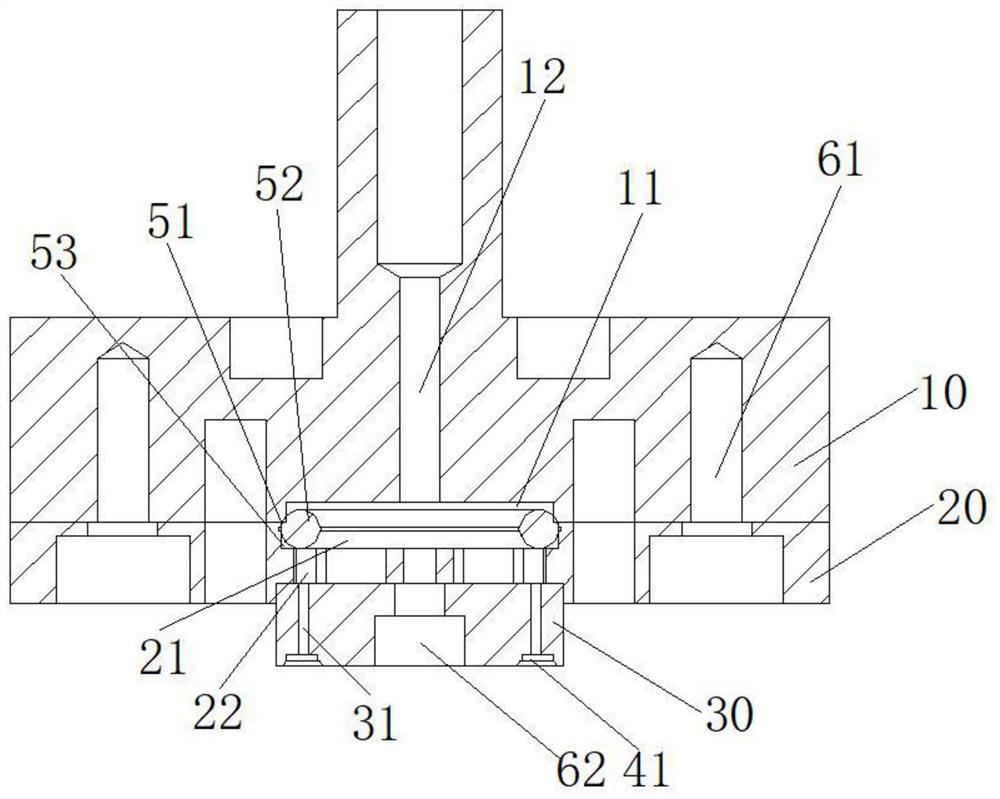

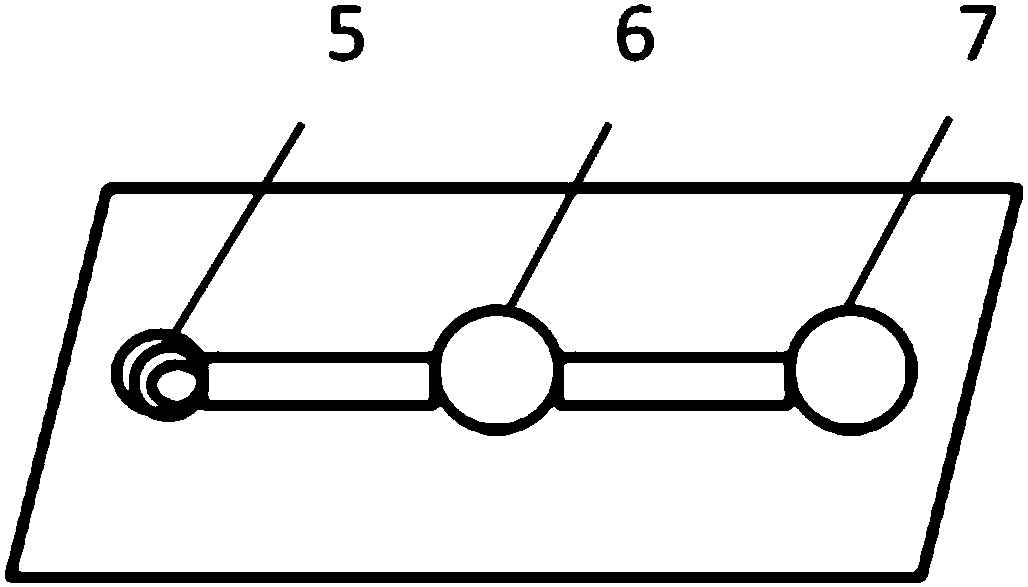

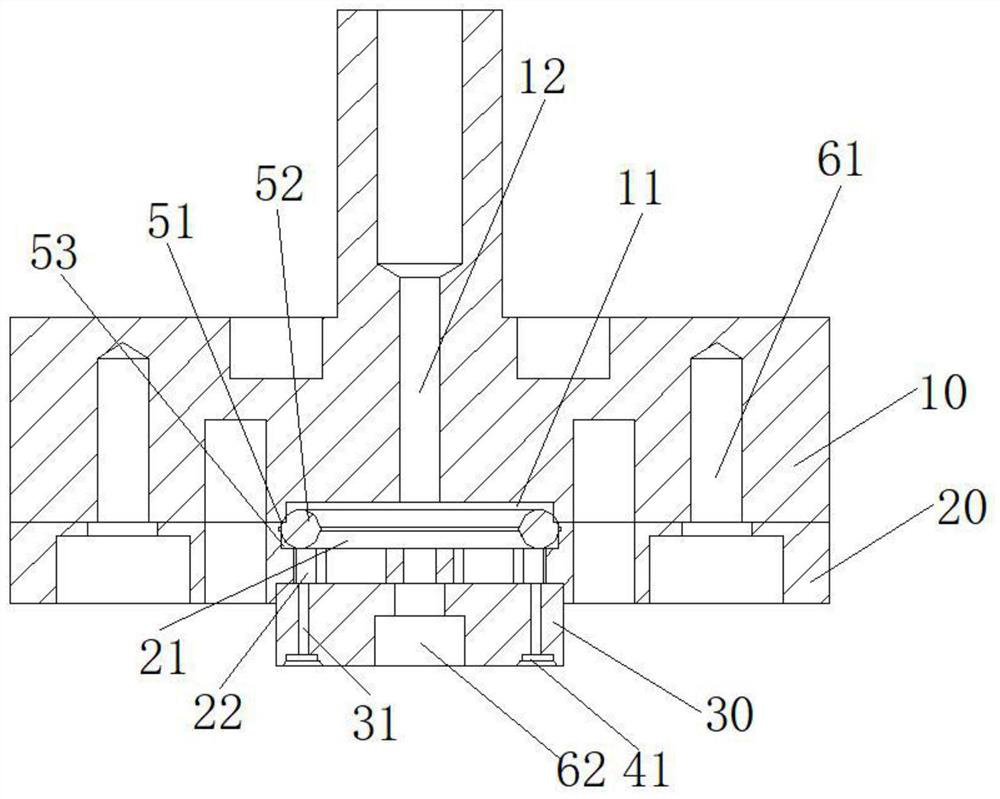

Suction head mechanism of annular product

The invention discloses a suction head mechanism of an annular product. The suction head mechanism comprises a guide seat, a mounting seat and a suction head module which are sequentially stacked fromtop to bottom, the guide seat is provided with a groove A and a channel A, the groove A is a circular groove, the mounting seat is provided with a groove B, a groove C and a plurality of channels B,and the groove B is a circular groove; the plurality of channels B are sequentially and uniformly distributed at intervals along a first loop line, the suction head module comprises a suction head main body and a plurality of suction nozzles, the suction head main body is provided with a plurality of channels C, the plurality of channels C are sequentially and uniformly distributed at intervals along a second loop line, the groove A and the groove B are oppositely combined up and down to form an air equalizing cavity and an annular butt joint seam; a sealing ring used for blocking the butt joint seam is arranged in the air equalizing cavity, the upper end of the suction head main body extends into the groove C, the channels B communicate with the channels C to form an air suction channelsin a one-to-one correspondence mode, and the suction nozzles are connected with the air suction channels in a one-to-one correspondence mode. According to the suction head mechanism of the annular product, the sealing ring is arranged between the two workpieces, so that air leakage of a gap between the two workpieces is prevented, and the air tightness is prevented from being influenced.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

Metal-welded plain double-vacuum-layer glass provided with edges sealed by sealing strips and sealing grooves and provided with mounting hole(s)

Metal-welded plain double-vacuum-layer glass provided with edges sealed by sealing strips and sealing grooves and provided with mounting hole(s) is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace; each air extracting hole is sealed by utilization of metal solder in a vacuum furnace; two sealed vacuum layers are formed among the three sheets of glass; and supports arranged in a point array are disposed in the vacuum layers. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

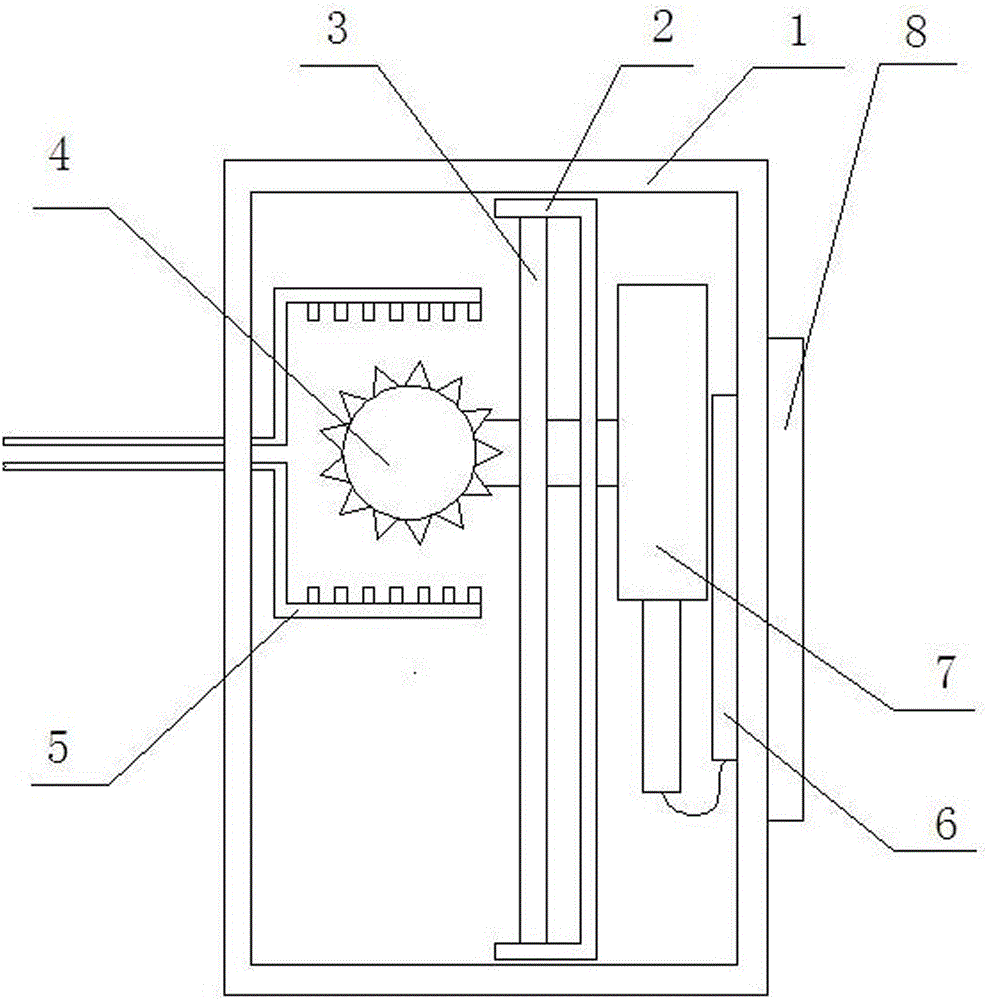

Specialized lever handle for bridge-cutoff aluminum alloy doors and windows

InactiveCN105041101APrevent air tightnessOvercoming the inability to lock automaticallyWing handlesWing knobsEngineeringControl circuit

The invention discloses a specialized lever handle for bridge-cutoff aluminum alloy doors and windows. The specialized lever handle comprises a shell, a supporting groove, a control circuit board, a motor and a separation and combination sheet and is characterized in that the supporting groove is formed in the middle of the interior of the shell, and the control circuit board, the motor and the separation and combination sheet are arranged in the shell; the control circuit board is connected to the motor, and a rotating shaft is arranged on the motor and is connected to a gear wheel which is connected to the separation and combination sheet in a toothing manner; and a circular hole is formed in the supporting groove, and the rotating shaft passes through the circular hole and is connected to the gear wheel. The specialized intelligent automatic lever handle for the bridge-cutoff aluminum alloy doors and windows is connected to a bridge-cutoff aluminum alloy door and window transmission and can automatically lock the bridge-cutoff aluminum alloy doors and windows, thereby realizing functions of prevention of loose airtightness, air leakage and rain leakage and burglary and the like.

Owner:HARBIN PENGLAI SCI & TECH DEV CO LTD

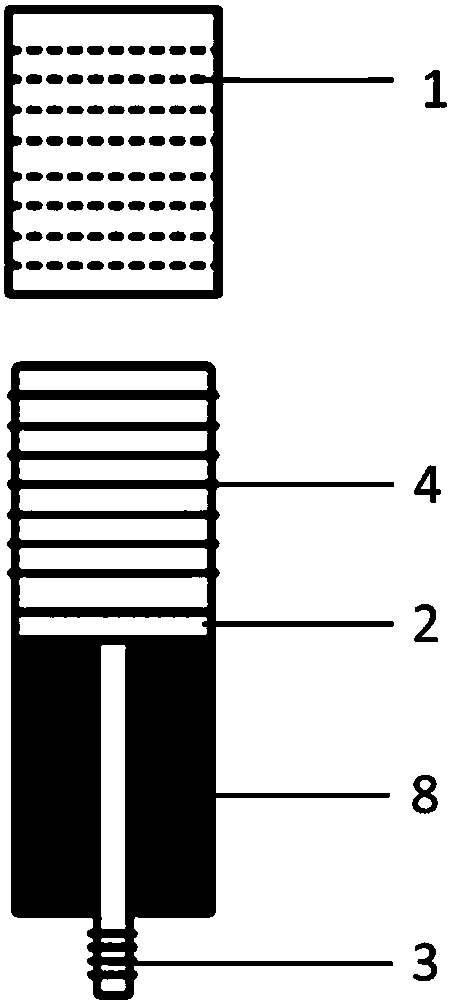

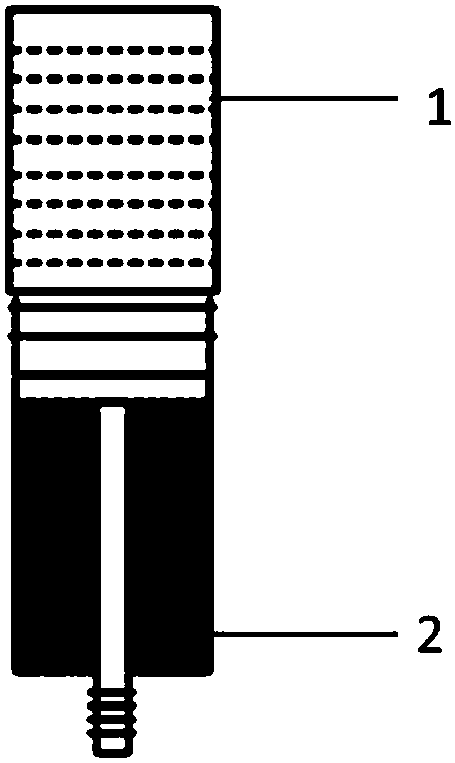

Manual sample injector capable of controlling sample injection volume and sample injection method and application thereof

PendingCN110470856AReduce size and complexityImprove convenienceLaboratory glasswaresMaterial analysisInjectorInjection equipment

The invention relates to the field of a sample injector, and discloses a manual sample injector capable of controlling sample injection volume and a sample injection method and an application thereof.The manual sample injector comprises a sample tank (2), a sample tank cover (1) and a sample discharging part (3); the sample tank cover (1) seals the sample tank (2) to form a sample cavity; the sample discharging part (3) is located on one side, opposite to the sample tank cover (1), of the sample tank (2); and the volume of the sample cavity can be changed through the movement of the sample tank cover (1), and a sample in the sample cavity is pressed out through the sample discharging part (3). According to the manual sample injector, the pressure intensity is increased through manual airpressure to realize sample injection, so that the pressure change is mild and controllable, a phenomenon of unstable sample injection caused by pressure fluctuation is avoided, the use of external sample injection equipment is avoided, and the size and the system complexity of the sample injector are greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Glass-welded plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743818AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The plain vacuum glass comprises upper glass and lower glass. The plain vacuum glass is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the middle glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace; one sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

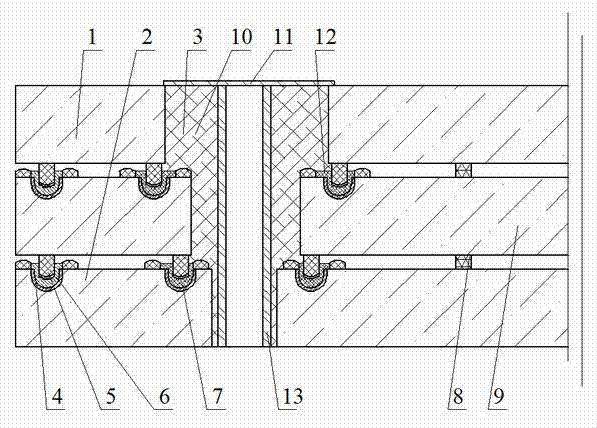

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

InactiveCN104743792AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the plain double-vacuum-layer glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each mounting hole are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and the mounting hole(s) are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass and the periphery of each mounting hole are welded under elevated pressure by glass solder in a vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: the convex vacuum glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; peripheries of the upper glass and the mounting hole(s) are provided with sealing strips; corresponding positions of the periphery of the lower glass and the mounting hole(s) are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded plain vacuum glass with installing holes and edge sealed by sealing strips

The invention relates to a metal-welded plain vacuum glass with installing holes and edge sealed by sealing strips, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through an alloy solder in an atmosphere heating furnace, and the extraction opening is enclosed by using metal solder in vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

Metal-welded convex vacuum glass having installing holes by metal welding at sealed edge of sealing strips

The invention relates to a convex vacuum glass having installing holes by metal welding at sealed edge of a sealing strip, which comprises an upper glass and a lower glass, the installing holes are provided, 1-4 installing holes are provided, at least a sealing strip is respectively provided at circumference of the upper glass and the installing hole, at least two sealing strips are provided at circumference of the lower glass, at least a sealing strip is arranged at the lower glass corresponding to the installing hole, the sealing strip of the upper glass is inserted between sealing strips of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a metal solder in a vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and usage life is increased.

Owner:戴长虹

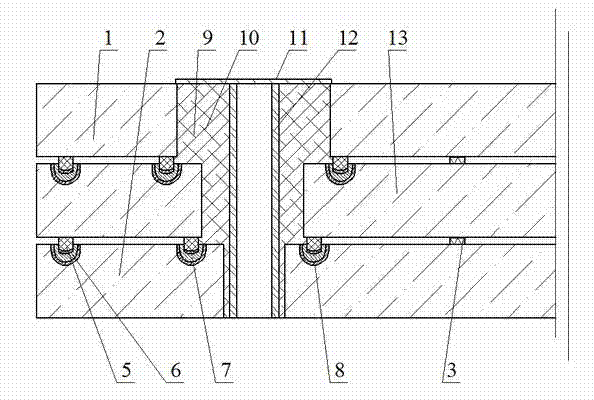

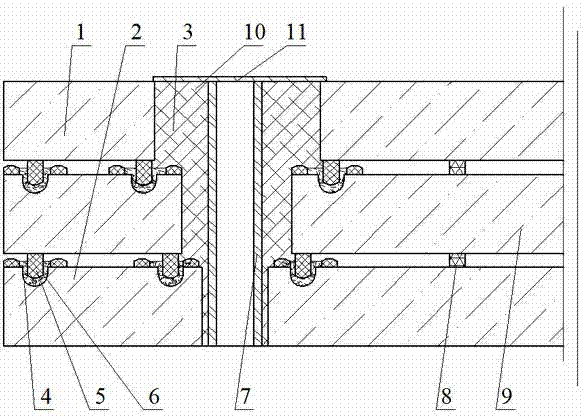

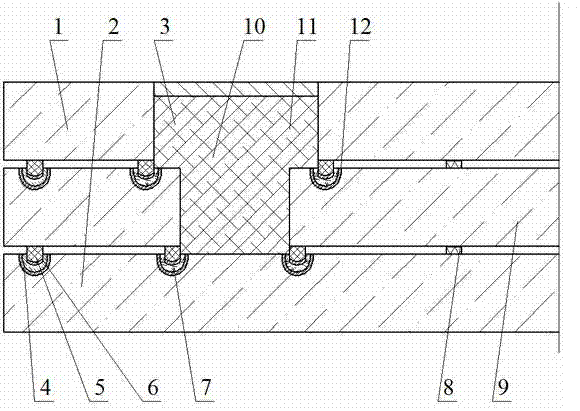

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing grooves and manufacturing method thereof

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass. The upper glass and the middle glass are provided with one to four air extracting holes. The lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves. After being heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. Two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded convex vacuum glass having installing holes with edge sealed by sealing strips

InactiveCN104743852AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

The invention relates to a glass-welded convex vacuum glass having installing holes with edge sealed by sealing strips, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

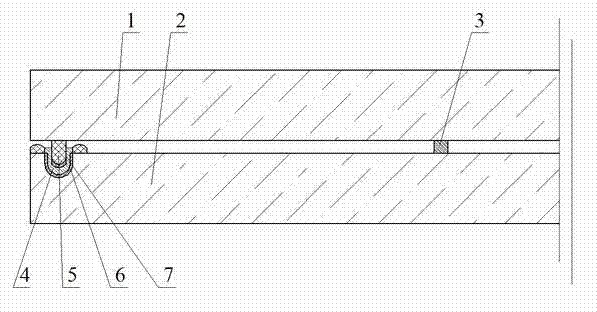

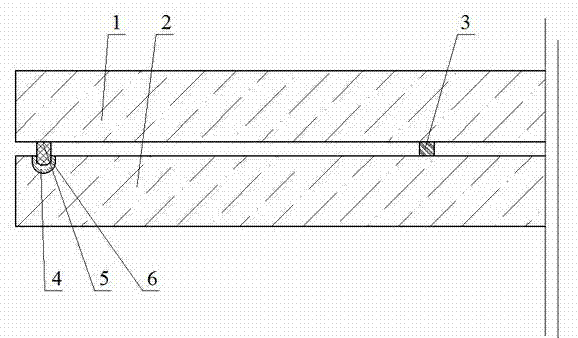

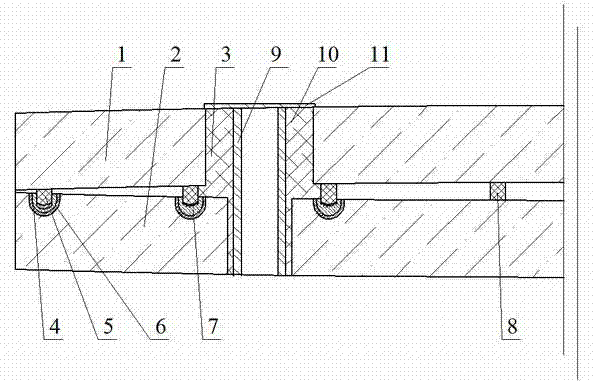

Glass-welded plane glass low-altitude glass with edge sealed by sealing grooves and production method thereof

InactiveCN104743865AShorten the timeMaintain tempered propertiesGlass reforming apparatusGlass productionHigh volume manufacturingHeating furnace

The invention relates to a glass-welded plane glass low-altitude glass with edge sealed by sealing grooves, which comprises an upper glass and a lower glass, a sealing strip is provided at the upper glass, a seal groove is arranged at circumference of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, an enclosing low-altitude layer is formed between the upper glass and the lower glass, and the supporters with lattice arrangement are arranged in the low-altitude layer. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

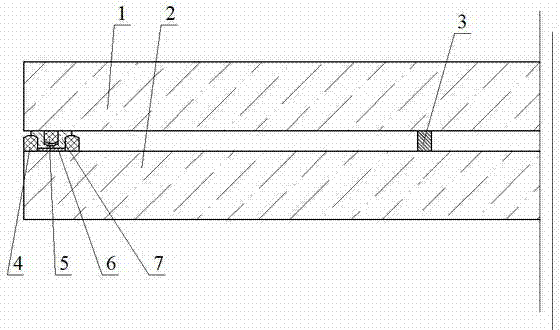

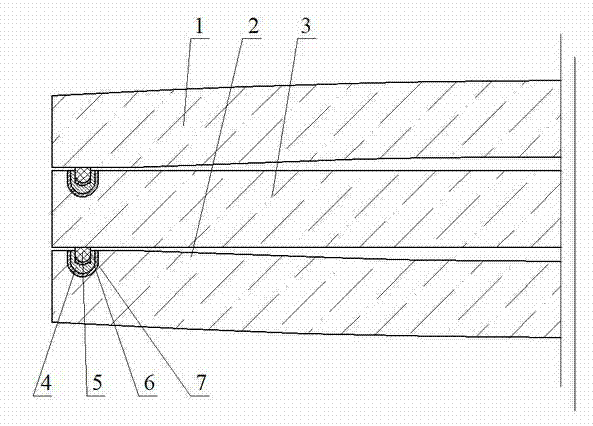

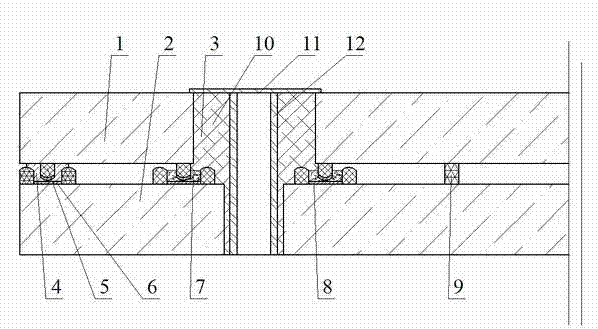

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing strips and manufacturing method thereof

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing strips is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass which are plain glass. The upper glass and the middle glass are provided with one to four air extracting holes. The periphery of the lower surface of the upper glass, the periphery of the lower surface of the middle glass and the periphery of each air extracting hole are respectively provided with at least one sealing strip. The peripheries of the upper surfaces of the middle glass and the lower glass are provided with at least two sealing strips. A position on the lower glass, which is corresponding to each air extracting hole, is provided with at least one sealing strip. Peripheries of the three sheets of glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. A manufacturing method of the plain double-vacuum-layer glass is simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the convex double-vacuum-layer glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each mounting hole are provided with sealing strips; corresponding positions of peripheries of the upper surfaces of the middle glass and the lower glass and the mounting hole(s) are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

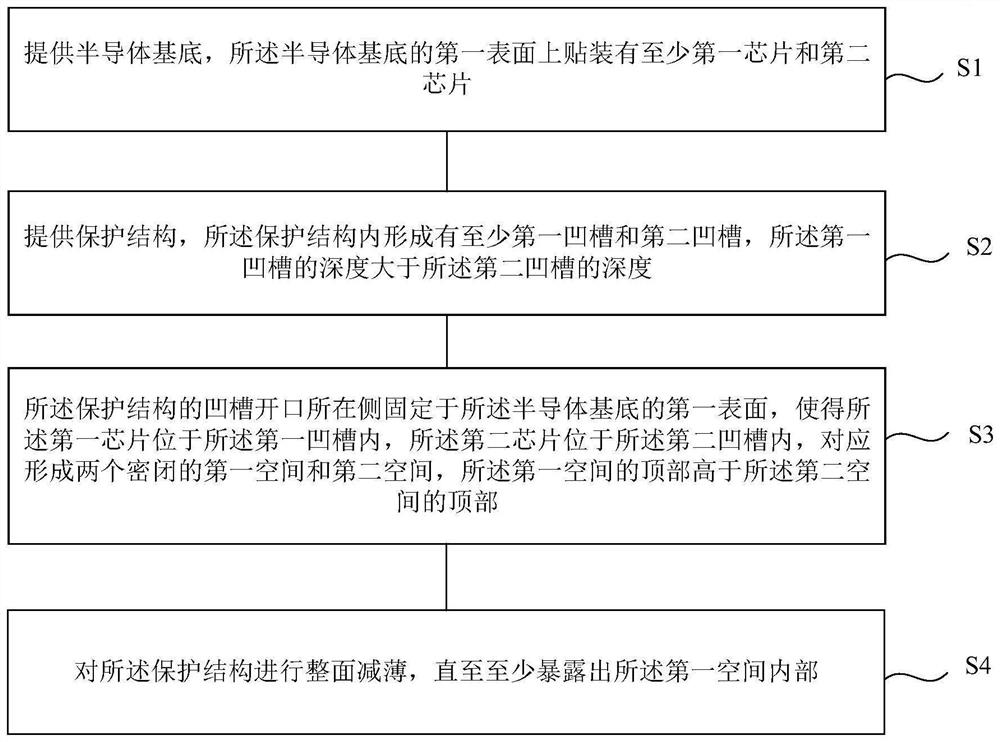

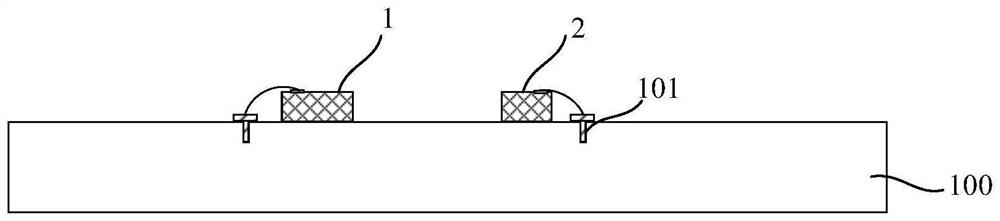

Chip packaging structure, forming method and electronic equipment

PendingCN114300932AAchieve nudityAchieve light transmissionLaser detailsSemiconductor lasersPhysicsEngineering

The invention discloses a chip packaging structure, a forming method and electronic equipment, the packaging structure comprises a semiconductor substrate, and at least a first chip and a second chip are mounted on the first surface of the semiconductor substrate; the protection structure is located on the first surface of the semiconductor substrate and comprises at least a first space and a second space, the first space is a first groove, the second space is a closed cavity, and a first depth from the bottom of the first groove to an opening is larger than a second depth from the bottom to the top in the closed cavity; the first chip is located at the bottom of the first groove, and the second chip is located at the bottom of the closed cavity. By means of the first groove with the first depth larger than the second depth and the closed cavity, the first chip located in the first groove can be exposed to achieve light transmission, and meanwhile the second chip with the requirement for air tightness is still located in the closed cavity to meet the air tightness requirement.

Owner:SHANGHAI JUYOU SMART INTELLIGENCE TECH CO LTD

Glass-welded plane double-low altitude-layer glass with edge sealed by sealing grooves and strips and production method thereof

InactiveCN104743855AShorten the timeMaintain tempered propertiesGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

The invention relates to a glass-welded plane double-low altitude-layer glass with edge sealed by sealing grooves and strips, which comprises an upper glass, a lower glass and an intermediate glass, the sealing strips are provided at lower surfaces of the upper glass and the intermediate glass, the seal groove and the sealing strips are arranged on the upper surface circumference of the intermediate glass and the lower glass, three glasses are rapidly heated, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and two enclosing low-altitude layers are formed between the upper glass and the intermediate glass as well as between the intermediate glass and the lower glass. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Suction head mechanism of a ring product

The invention discloses a suction head mechanism for annular products, which comprises a guide seat, an installation seat and a suction head module stacked sequentially from top to bottom, the guide seat is provided with a groove A and a channel A, and the groove A is a circular concave Groove, the mounting seat is provided with groove B, groove C and several channels B, the groove B is a circular groove, and several channels B are evenly spaced along the first ring line, and the suction head module includes the suction head body and several suction heads. Nozzle, the main body of the suction head is provided with a number of channels C, and the dry channels C are evenly spaced along the second ring line. There is a sealing ring for sealing the butt joint inside, the upper end of the suction head body extends into the groove C and the channel B and the channel C are connected one by one to form an inhalation channel, and the suction nozzle and the inhalation channel are one by one corresponding connection. The sealing ring in the present invention is arranged between two workpieces to prevent air leakage between the two workpieces and affect the air tightness.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

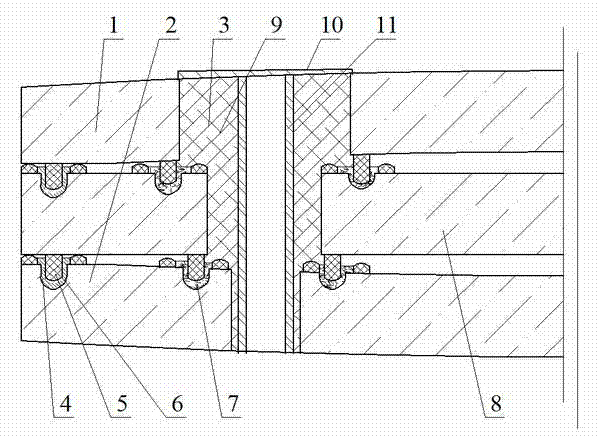

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743795AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the upper surfaces of the upper glass and the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and two vacuum layers are formed among the upper glass, the lower glass and the middle glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: the convex vacuum glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the upper glass and the lower glass are convex glass; peripheries of the upper glass and the mounting hole(s) are provided with sealing strips; corresponding positions of the periphery of the lower glass and the mounting hole(s) are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743833AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the lower surfaces of the upper glass and the middle glass are provided with sealing strips; the peripheries of the upper surfaces of the middle glass and the lower glass are provided with the sealing grooves; after being rapidly heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; and two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

InactiveCN104743815AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

InactiveCN104743831AShorten the timeAvoid pollutionGlass reforming apparatusGlass productionHigh volume manufacturingFused glass

Glass-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com